Table of Contents

Wood lathe accessories are a must for every woodturner: lathe light, drill chucks, negetive rake scraper, curved tool rest, live center set, dust hood, thickness calipers, digital micrometer, paste wax, Drive centers, etc.

Lathe Light

Detailed Overview:

- Function: The lathe light is specifically designed to illuminate the work area on a wood lathe, focusing on the interior of bowls or vessels being turned.

- Key Features: These lights often come with a magnetic base, making them easy to attach and adjust on the lathe or other metal surfaces. They are designed to be sturdy enough to withstand vibrations from the lathe.

- Benefits: The primary benefit is improved visibility, especially in dusty conditions common in woodturning. This better illumination helps identify and work on fine details, ensuring a higher quality finish and avoiding missed imperfections like scratches or swirl marks.

Drill Chuck

Detailed Overview:

- Function: A drill chuck attachment allows the wood lathe to be used as a drill press. It is beneficial for drilling holes longitudinally through the center of a workpiece.

- Key Features: This attachment can be particularly advantageous in workshops where space is limited, eliminating the need for a separate drill press.

- Benefits: The drill chuck enhances the wood lathe’s versatility, making it suitable for a broader range of tasks. It’s especially beneficial for boring deep holes accurately, and its ease of use makes it appealing to beginners and experienced woodturners.

Negative Rake Scraper

Detailed Overview:

- Function: The negative rake scraper is designed to smooth the wood surface in the finishing stages of woodturning.

- Key Features: This tool requires regular sharpening to maintain its effectiveness. Its design helps balance during the cutting process, leading to a smoother finish.

- Benefits: The main advantage of using a negative rake scraper is the superior surface finish it can provide. While it requires more maintenance in sharpening, the resulting smoothness of the turned wood piece is often worth the extra effort.

Curved Tool Rest

Detailed Overview:

- Function: A curved tool rest is designed to support the turning tools while working on bowls‘ interior and exterior curves.

- Key Features: These rests come in various shapes, but the curved design is specifically beneficial for reaching the bottom of deep bowls. They can usually accommodate bowls of up to 12 inches in depth.

- Benefits: The primary benefit is its increased control and reach, especially for deeper and more intricate bowl designs. This leads to more precise turning and better overall project outcomes.

Live Center Set

Detailed Overview:

- Function: A live center is placed in the tailstock of a lathe and supports the end of the workpiece, allowing it to rotate freely.

- Key Features: High-quality live centers are designed to minimize the mark left on the workpiece. They come in various sizes and styles to accommodate different project requirements.

- Benefits: The live center set adds stability to the workpiece, reducing wobble and vibration. This stability is crucial for achieving accuracy in turning, especially for longer or heavier workpieces.

Dust Hood

Detailed Overview:

- Function: A dust hood is designed to capture and manage the dust and chips generated during woodturning.

- Key Features: These hoods come in various sizes to fit different workspaces and lathes. They are typically positioned close to the work area to collect dust as it’s produced effectively.

- Benefits: The primary benefit is a cleaner and safer workspace. Dust collection is crucial for reducing the risk of respiratory issues and fire hazards due to dust accumulation. A well-placed dust hood also significantly reduces cleanup time after woodturning sessions.

Thickness Calipers

Detailed Overview:

- Function: Thickness calipers measure the thickness of materials, and they are particularly useful in turning applications like bowl and vessel walls.

- Key Features: These calipers provide precise measurements, which are crucial for ensuring uniform thickness in woodturning projects.

- Benefits: The main advantage is the ability to achieve consistent thickness across a workpiece, which is essential for both the aesthetic and functional aspects of woodturning. It helps avoid the common mistake of uneven wall thickness.

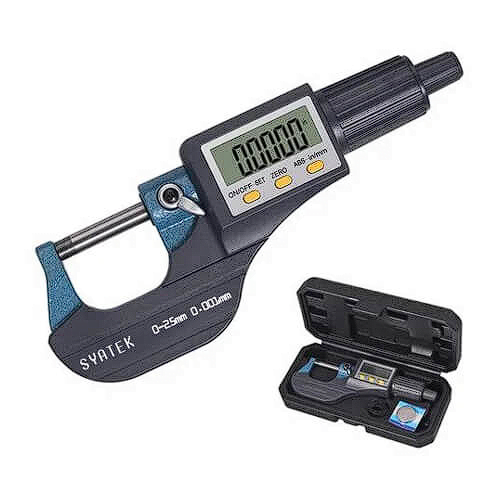

Digital Micrometer

Detailed Overview:

- Function: A digital micrometer provides highly accurate measurements, essential for precise woodturning tasks.

- Key Features: It offers digital precision, setting and maintaining exact measurements, particularly useful for repetitive tasks.

- Benefits: It’s invaluable for projects that require consistent dimensions, like fitted lids or rings. The digital display makes reading measurements easy and accurate, enhancing the overall quality of the workpiece.

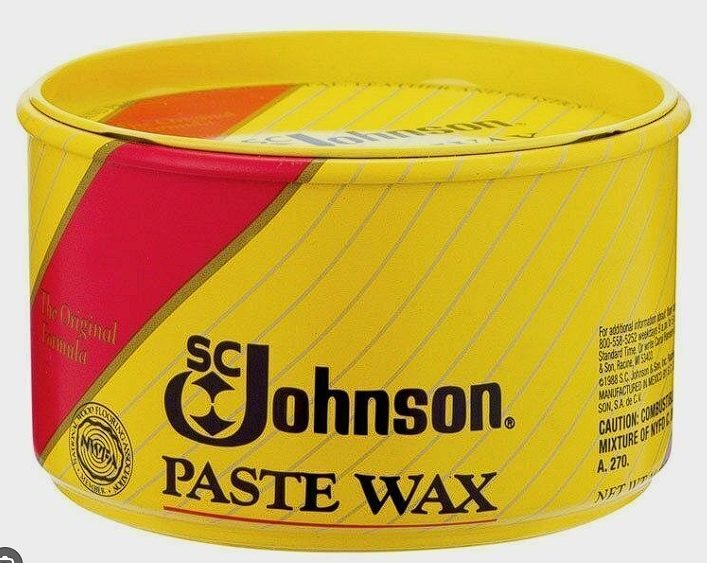

Paste Wax

Detailed Overview:

- Function: Paste wax lubricates parts of the lathe, such as the tailstock, to allow for smoother movement.

- Key Features: This wax is designed to reduce friction and facilitate the smooth operation of moving parts on the lathe.

- Benefits: By ensuring smooth movement, paste wax aids in making precise adjustments during woodturning. This leads to better control over the turning process and can improve the overall quality of the finished workpiece.

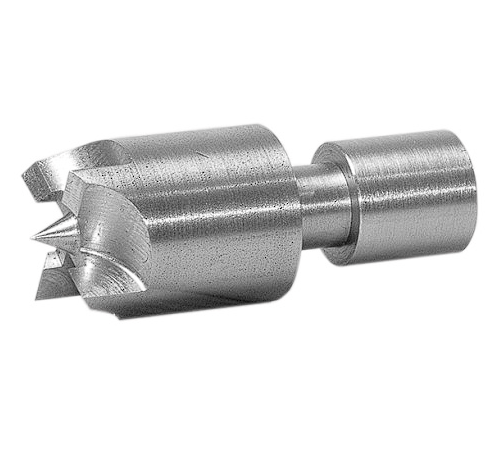

Drive Center

Detailed Overview:

- Function: A drive center secures the workpiece onto the lathe, offering additional gripping power.

- Key Features: It typically features a spring-loaded center pin and small teeth, providing a solid grip without leaving significant marks on the wood.

- Benefits: The enhanced gripping power ensures the workpiece stays secure during turning, which is particularly important for intricate or delicate projects. The design minimizes damage to the wood, maintaining the integrity of the workpiece.

Best Wood Lathe Attachments to Consider

Expanding Capabilities

Wood lathe attachments can significantly broaden your woodworking capabilities. You can take your craft to new heights with specialized attachments like steady rests, bowl gouges, spindle savers, and solid steel rods. These accessories (scratch, holes, solid steel rod, top rod) are designed to help you create intricate designs and achieve smoother finishes on your woodturning projects.

For instance, a steady rest attachment provides support for longer or thinner workpieces, reducing vibrations and enhancing safety during turning. This is especially helpful when working with delicate materials, such as wood blanks, that require extra stability.

Bowl gouges, featuring a solid steel rod, are essential tools for shaping concave curves in wooden bowls or similar projects. They allow for precise control over the depth and shape of the cuts, enabling you to create stunning pieces using solid steel rods easily.

Specialized Functionality

Wood lathe attachments’ specialized functionality and features, including solid steel and top rods, allow woodworkers to tackle diverse projects with precision and efficiency. For example, spindle savers are designed to protect the delicate tips of spindles from scratch and damage during turning processes. By using this attachment, you can ensure that your spindles remain intact throughout the entire turning operation.

Moreover, these attachments, featuring a solid steel rod as the top rod, enable woodworkers to explore techniques such as thread cutting or fluting without investing in separate machinery or tools. This not only enhances versatility but also saves space in woodworking endeavors.

In addition to their functional benefits, these attachments provide an avenue for creativity by offering unique ways to manipulate wood into different shapes and forms.

The Role of Tool Rests in Wood-Turning

Stability and Support

Wood lathe attachments and accessories, such as solid steel tools that rest with a long post, are crucial in providing stability and support for wood-turning tools during the shaping process. When working with wood blanks, a reliable solid steel tool rest is essential to ensure precise and controlled movements while turning the wood. Different tool rests, including curved or straight designs, offer varying levels of control and ease of use. For instance, a curved tool rest with solid steel features might be preferred when shaping intricate details on the wood, while a straight tool rest could provide more stability for roughing cuts.

When using solid steel wood lathe attachments like chisels or gouges to shape the wood, proper positioning and adjustment of the top tool rest are paramount for safe and efficient woodturning. By securely locking the solid steel tool rest at the top, turners can minimize vibrations that may lead to unwanted scratches or irregularities on their projects.

Positioning and Adjustment

Correctly adjusting the height of the solid steel tool rest top according to different sizes of wood blanks is also essential, as it allows turners to maintain consistent cutting angles throughout their work. Moreover, ensuring no obstructions between the top rod (banjo) holding the solid steel tool rest and its contact point with the iron body prevents unnecessary accidents during turning.

In addition to these safety considerations, understanding how different types of solid steel tool rests function can significantly enhance one’s ability to produce high-quality turned items. For example, experienced turners may find that certain styles suit specific applications better than others based on personal preferences or project requirements.

Headstock Spindle Adapters and Their Uses

Expanding Versatility

Wood lathe attachments, accessories, solid steel, and top are essential for enhancing the functionality of your lathe. One crucial accessory to consider is the solid steel headstock spindle adapter, which allows you to use a variety of different-sized attachments on your lathe’s spindle. These reliable steel adapters connect the lathe’s spindle and various accessories, such as faceplates, chucks, or other attachments with varying thread sizes.

By investing in a set of solid steel headstock spindle adapters, woodturners can significantly expand the versatility of their top lathes. This means you can easily switch between different attachments without needing multiple lathes or permanently modifying your existing equipment. Whether you’re working on a large bowl using a chuck or turning smaller items with a faceplate, having access to these steel adapters ensures you have the right tool for any project.

Having used steel headstock spindle adapters extensively in my woodworking projects, I’ve found they offer convenience and flexibility when transitioning between different turning tasks. For instance, when I needed to switch from using a steel faceplate for creating bowls to employing a steel chuck for turning smaller spindles, having the appropriate adapter readily available saved me time and effort.

Compatibility and Convenience

The beauty of steel headstock spindle adapters lies in their ability to accommodate accessories with varying thread sizes. This steel compatibility ensures that woodturners can seamlessly connect different tools without worrying about mismatched threads. These steel adapters provide convenience by eliminating the need for separate spindles dedicated to specific attachment types.

With steel headstock spindle adapters at your disposal, you do no need to invest in multiple specialized spindles or worry about finding compatible accessories for each thread size. Instead, woodworkers can focus on honing their craft while enjoying the ease of transitioning between diverse turning applications and steel.

The Importance of Steel Faceplates in Woodworking

Secure Workpiece Attachment

Steel faceplates are crucial wood lathe attachments and accessories that provide a reliable attachment point for workpieces during woodturning. They securely hold the wood, preventing unwanted movements or shifts while turning. This stability is essential for achieving precise cuts and creating smooth, symmetrical shapes.

Steel faceplates minimize vibrations during woodturning, resulting in smoother cuts and better overall control. Reducing vibrations helps prevent the workpiece from shifting or wobbling on the lathe, allowing woodworkers to achieve more accurate results. This enhanced stability also contributes to a safer working environment by reducing the risk of unexpected movements while operating the lathe.

Versatility in Size

One key advantage of steel faceplates is their availability in various sizes to accommodate different project requirements. Whether working on small-scale intricate designs or larger pieces such as bowls or platters, having a range of solid steel faceplate options allows woodworkers to select the most suitable size for each project. This versatility ensures they can effectively secure various workpieces without compromising stability or safety.

In my Experience, using high-quality steel faceplates has significantly improved the precision and overall finish of my woodworking projects. The ability to choose from different sizes based on my project needs has been incredibly beneficial, providing me with greater flexibility and control over my woodturning process.

Benefits of a Plastic Center Finder for Lathes

Simplifies Center Point Location

A plastic center finder is an essential accessory for wood lathe users as it simplifies locating the center point on a workpiece. Using a plastic center finder, woodturners can quickly and accurately identify the exact middle of their workpiece, ensuring precision in their turning projects. This tool eliminates manual measurements and guesswork when determining the center point, saving time and reducing errors.

Woodworkers often encounter challenges when mounting irregularly shaped or asymmetrical workpieces onto their lathe’s spindle or faceplate. A plastic center finder helps address this issue by providing a reliable method for finding the precise midpoint regardless of the workpiece’s shape or size. This ensures that workpieces are securely aligned with the lathe’s spindle or faceplate, resulting in smoother turning operations and improved overall craftsmanship.

Lightweight and Durable Tool

The lightweight nature of plastic center finders makes them easy to handle and maneuver during woodworking tasks. Unlike heavier metal alternatives, plastic center finders offer convenience without compromising accuracy. These tools are durable enough to withstand regular use without wearing out quickly. Their resilience makes them suitable for both beginners and experienced woodturners who require a reliable yet low-maintenance tool to aid them in achieving precise results consistently.

In my Experience as a woodworker, having a plastic center finder has significantly enhanced my efficiency in setting up workpieces on my lathe while ensuring they are perfectly aligned each time. This tool’s simplicity and effectiveness have made it an indispensable part of my woodworking toolkit.

Revolving Centers: Enhancing Wood Lathe Precision

Smooth Rotation

Revolving centers, or live centers, are essential wood lathe attachments and accessories that provide crucial support to the tailstock end of the lathe. They play a vital role in ensuring smooth workpiece rotation during turning. Revolving centers help maintain precision and accuracy throughout the woodturning process by reducing friction and heat buildup.

Revolving centers come with different tip designs tailored to specific turning applications. For instance, a cone-shaped center is suitable for general-purpose turning, while a cup center is ideal for supporting hollow workpieces such as vases or bowls. These variations allow woodworkers to choose the most appropriate revolving center based on their project requirements.

Personal Experience: using a revolving center significantly improves my woodturning experience by providing consistent support and minimizing vibration. This has helped me achieve smoother finishes on my turned pieces.

Tailored Turning Applications

The versatility of revolving centers makes them indispensable accessories for wood lathes. Whether spindle turning, bowl turning, or creating intricate details on furniture components, these attachments ensure that the workpiece rotates seamlessly without compromising precision.

Some advanced revolving centers feature interchangeable tips that can be swapped out to accommodate different types of projects. This adaptability allows woodworkers to explore various turning techniques without investing in multiple specialized tools.

Essential Accessories for Advanced Wood Lathe Turning

Hollowing Systems

Hollowing systems are essential accessories for advanced wood lathe turning, allowing the creation of hollow forms like vases and bowls. These systems consist of tools designed to reach inside a turned piece and remove material from within. Using a hollowing system, woodturners can achieve intricate designs that are impossible with traditional turning tools. For example, the Easy Hollower tool set offers different configurations for varying project needs.

Captive Ring Tools

Captive ring tools are specialized accessories that create decorative rings on spindle turnings without parting off the workpiece. These unique tools enable woodturners to produce stunning projects such as napkin rings and curtain rod finials with integrated captive rings. The Sorby captive ring tool is popular among woodturners due to its versatility and ease of use.

Eccentric Chuck Sets

Eccentric chuck sets, or off-center chuck sets, allow woodturners to create strange or off-center turnings. This allows for the production of asymmetrical pieces, such as goblets and candlesticks, that feature non-concentric shapes. The Oneway Talon chuck set is widely favored by experienced woodturners for its precision and flexibility in achieving diverse eccentric turning designs.

Incorporating these wood lathe attachments and accessories into advanced woodturning projects opens new creative avenues for producing complex and visually captivating wooden creations.

Tips for Locating Quality Wood Lathe Accessories

Material Quality

When selecting wood lathe attachments and accessories, it’s crucial to prioritize material quality. Look for accessories made from sturdy materials like high-speed steel or carbide, which ensure longevity and precision in your woodturning projects. High-quality materials also contribute to smoother finishes and reduce the risk of accidents or tool breakage during operation.

Investing in durable wood lathe accessories that can withstand the demands of turning dense hardwoods or large-scale projects is essential. For example, a robust chuck made from solid steel will provide the strength to hold workpieces securely without compromising stability. This durability is critical for maintaining safety standards while working with heavy, unbalanced blanks.

Compatibility and Reviews

Before purchasing, consider the compatibility of wood lathe attachments with your specific lathe model. Always check if an accessory is designed to fit your machine’s spindle size and thread type, ensuring seamless integration and optimal performance. Reading reviews from fellow woodturners about their experiences with certain accessories can offer valuable insights into product reliability and performance.

Seeking recommendations from experienced woodturners can help you identify reputable brands known for producing top-quality lathe accessories. Their firsthand knowledge can guide you toward reliable products that align with your turning needs while avoiding subpar options that may compromise your woodworking experience.

Price Comparison

While searching for wood lathe accessories, comparing prices across different retailers or online stores is wise. By doing so, you can find competitive deals without sacrificing quality. Watch for special promotions or discounts on reputable platforms, allowing you to acquire high-grade tools at more affordable prices.

Conclusion and Final Thoughts on Wood Lathe Upgrades

In exploring the wood lathe attachments and accessories world, I’ve highlighted the crucial role of tool rests, headstock spindle adapters, steel faceplates, plastic center finders, and revolving centers in enhancing wood lathe precision and woodworking efficiency. These upgrades are essential for advanced wood lathe turning, providing the necessary support for creating intricate designs and achieving superior craftsmanship. When locating quality wood lathe accessories, it’s imperative to consider their material, design, and compatibility with specific lathe models to ensure seamless integration and optimal performance.

As you continue your journey in woodturning, I encourage you to invest in these essential attachments and accessories to elevate your woodworking experience. Remember to prioritize quality and compatibility when selecting these upgrades, as they will significantly impact the precision and versatility of your wood lathe. Happy turning!

Frequently Asked Questions

What are some essential wood lathe attachments and accessories?

Wood lathe attachments and accessories such as tool rests, headstock spindle adapters, steel faceplates, revolving centers, and plastic center finders are essential for enhancing precision and expanding the capabilities of your wood lathe.

How does a tool contribute to woodturning?

Tool rests support woodturning tools during shaping, ensuring stability and control. They help maintain consistent cutting angles and reduce the risk of accidents or errors while working on a lathe.

What is the role of headstock spindle adapters in woodworking?

Headstock spindle adapters enable you to use different sizes of chucks or accessories with your lathe. They provide versatility by allowing you to mount various work holding devices onto your lathe’s headstock spindle.

Why are steel faceplates important in woodworking?

Steel faceplates offer durability and stability when mounting workpieces onto a lathe. Their sturdy construction ensures secure attachment, crucial for safe and efficient woodturning operations.

What benefits does a plastic center finder offer for lathes?

A plastic center finder simplifies locating the exact center on both square and round stock. It provides accuracy and convenience when setting up workpieces on a lathe, leading to improved precision in turning projects.

How can I enhance wood lathe precision with revolving centers?

Revolving centers facilitate smoother rotation of workpieces on a lathe by reducing friction. They improve accuracy by supporting the tail end of the workpiece with minimal resistance, resulting in cleaner cuts and enhanced overall precision.

Where can I find quality wood lathe accessories?

Quality wood lathe accessories can be found at reputable woodworking supply stores, online marketplaces specializing in woodworking tools, or directly from manufacturers’ websites. Look for products that receive positive reviews from experienced turners to ensure reliability.