Table of Contents

Professional woodturning requires essential tools and equipment, including a durable lathe, sharp chisels, gouges for shaping, parting tools, calipers for measuring, and safety gear like face shields and dust masks. Quality lathes, specialized chisels, and gouges ensure precision and safety for detailed work on various kinds of wood. Calipers help skilled artisans maintain accuracy in dimensions, and robust safety equipment is crucial for protecting the woodturner during the process.

Essential Woodturning Tools for Professional Craftsmanship

1. Lathe: The Cornerstone

A lathe is the heart of a woodturner’s workshop, enabling the turning and shaping of wood. It allows artisans to create various cylindrical forms such as table legs, candlesticks, and bowls. With its rotating mechanism, the shaft provides the foundation for crafting exquisite wooden pieces.

Artisans rely on their lathes, shafts, and cutters to create precise designs and unique shapes that define their craftsmanship. For example, using different lathe speeds and techniques, they can produce intricate patterns or smooth curves using a cutter.

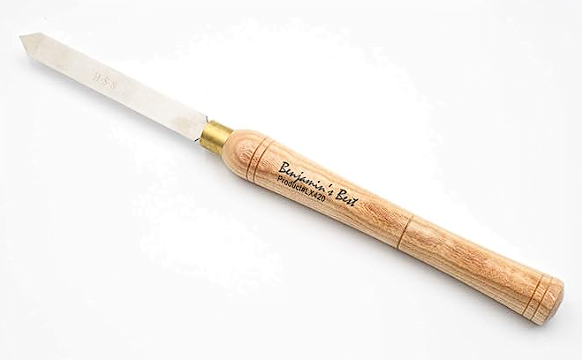

different types of Chisel

2. Chisels and Gouges: Essential Cutting Tools

Chisels, gouges, and cutters are indispensable cutting tools for any skilled woodturner. These tools allow artisans to shape, hollow out, detail, and use cutters to smoothen the surfaces of turned wood pieces. They come in various sizes and shapes to cater to different hanging needs, cutters, and quantities.

When I started my journey into professional woodturning, understanding how each cutter or gouge interacts with the wood was crucial for mastering this craft. Learning to handle these tools, such as the cutter, has significantly improved my woodworking skills.

3. Parting Tool: Separating Turned Pieces

Once the shaping process is complete, the parting tool, a cutter or cutoff tool, is vital for separating turned wooden pieces from the lathe. This thin blade-like cutter tool ensures a clean cut without damaging the finished piece or risking injury during removal from the lathe.

In my years of experience working with professional woodturning tools and equipment, such as parting tools and cutters, I’ve found that having a reliable one makes all the difference in achieving seamless results when finishing turned items.

Choosing the Right Chuck and Jaw for Your Lathe

4. Chuck and Jaw Options

Choosing the suitable chuck and jaw combination is crucial when selecting professional woodturning tools and equipment. Chucks offer various gripping options, such as dovetail or expanding jaws. These options provide versatility in securing different shapes and sizes of workpieces during turning and quantity. For instance, dovetail jaws are ideal for holding bowls, while expanding jaws are suitable for gripping small spindles.

When choosing a chuck and jaw set, it’s essential to consider factors like size compatibility, ease of use, durability, and quantity. The chuck quantity should match your lathe’s spindle thread size to ensure a secure fit. Opting for durable materials like steel provides longevity, especially when working on heavy-duty projects. Ease of use is also critical – look for chucks with smooth operation mechanisms that allow quick adjustments between different projects.

Personal Insights

In my experience with woodturning tools, I’ve found that investing in a versatile chuck with interchangeable jaws significantly expands my range of projects./// Having multiple sets of jaws allows me to effortlessly transition from turning intricate pens to crafting more giant bowls without investing in separate chucks.

Furthermore, considering the ease of swapping out different jaw sets and the quantity, it has saved me valuable time during complex projects where efficiency is critical. Ultimately, choosing professional woodturning tools that offer both security and adaptability in quantity has dramatically enhanced my craftsmanship.

Importance of Specialty Cutters and Sharpening Systems

5. Specialty Cutters

Specialty cutters, such as scrapers or hollowing tools, are essential for specific woodturning techniques. For instance, a scraper and a hollowing tool are used to smooth out the turning surface and create internal contours within the wood, respectively. These specialized tools enable woodworkers to achieve precise shapes and finish with a number of cuts that may not be attainable with standard cutting tools.

Using these specialty cutters allows for greater creative freedom in woodturning projects. They allow for the execution of intricate designs and details that enhance the overall quality of turned items. They offer versatility by enabling woodworkers to work effectively with various types of wood.

Personal note: I find that having a diverse selection of specialty cutters expands my capabilities as a woodturner. It allows me to experiment with different styles and designs, leading to unique and personalized creations.

6. Sharpening Systems

Keeping woodturning tools sharp is crucial for achieving clean cuts and reducing strain on the lathe motor. A reliable sharpening system is integral in maintaining the effectiveness of professional woodturning tools. Grinding wheels, honing guides, or diamond sharpening stones are standard components of sharpening systems used by woodturners.

A well-sharpened cutter ensures smoother cutting actions and reduces tear-out during turning processes. This results in improved efficiency when working on various woodworking projects while contributing to better overall safety in the workshop environment.

Advanced Lathes and Accessories for Expert Turners

Enhanced Features

Advanced woodturning lathes come with a range of enhanced features that cater to the needs of professional woodturners. These lathes are equipped with variable speed control, allowing turners to adjust the speed according to the specific requirements of each project. Including digital readouts provides precise measurements, ensuring accuracy and consistency in turning operations. Advanced lathes often feature swiveling headstocks, which offer increased versatility by enabling turners to position their workpieces at various angles.

Expert woodturners can significantly benefit from these advanced features as they provide greater control over turning, resulting in high-quality and intricate designs.

Expandable Capabilities

In addition to advanced features, expert turners can enhance their woodturning capabilities through various accessories. Steady rests are crucial in stabilizing longer workpieces during turning, while faceplates enable secure attachment of irregularly shaped blanks. Tailstock extensions further expand the reach of the lathe’s tailstock, accommodating larger projects with ease.

For instance, my precision and efficiency improved significantly when I started using a lathe with variable speed control and digital readouts. This allowed me to take on more complex projects without compromising on quality.

Larger Capacity and Multiple Spindle Options

Lathes designed for expert turners often boast larger swing capacities and multiple spindle options. A larger swing capacity enables turners to work on larger-diameter pieces while maintaining stability throughout the turning process. Moreover, numerous spindle options allow for the simultaneous mounting of different tools or chucks, streamlining production processes for seasoned professionals.

Combining these enhanced features and versatile accessories empowers expert woodturners to tackle diverse projects with confidence and finesse.

Enhancing Woodturning Techniques with Quality Equipment

Precision Enhancement

Investing in professional woodturning tools and equipment can significantly enhance your precision and control. High-quality tools like skew chisels or spindle gouges allow for intricate detailing and smoother finishes. With these specialized tools, you can achieve a level of precision that is simply unattainable with standard equipment.

The upgrade to quality woodturning equipment also reduces vibration, improves stability, and minimizes the risk of accidents during turning. This means you can work more confidently on your projects without worrying about potential mishaps due to unstable or low-quality tools.

Improved Woodturning Experience

Using professional-grade woodturning tools, turners can elevate their creativity to new heights. The enhanced control provided by these tools allows for exploring new techniques like negative rake scraping, opening up a new realm of creative possibilities. Moreover, the improved stability from high-quality equipment enables turners to execute neutral techniques with greater ease and finesse.

In my experience, upgrading to professional woodturning tools has improved the quality of my finished pieces and made the entire process more enjoyable. The satisfaction derived from working with top-notch equipment is unparalleled, making it a worthwhile investment for any severe woodturner.

Maximizing Efficiency with Fast Shipping and Diverse Accessories

Fast shipping is crucial for ensuring the timely delivery of accessories and tools. This minimizes downtime in the workshop, allowing woodturners to resume their projects quickly. For example, if a woodturner urgently needs a new collet or faceplate, fast shipping ensures that these essential items arrive promptly.

Fast shipping also plays a vital role in maintaining an efficient workflow in the workshop. Woodturners can rely on receiving their tools and accessories within a short timeframe, enabling them to plan and execute their projects without unnecessary delays. Quick delivery allows professionals to focus on their craft without worrying about extended waiting periods, whether it’s high-speed steel turning tools or carbide inserts.

Diverse Accessories

Diverse accessories such as collets, centers, or faceplates provide flexibility for various woodturning projects. A wide range of readily available accessories allows for efficient workflow and quick project setup. For instance, when working with dense exotics or other challenging materials like m2 steel or dynamic brand tools, specialized accessories that are readily accessible are required.

Woodturners can benefit from access to various collet sizes and types depending on the project at hand. This adaptability ensures they can easily tackle different turning tasks while maximizing efficiency in the workshop.

Flexibility for Projects

The availability of diverse accessories offers greater flexibility for efficiently tackling different types of woodturning projects. For instance, if I’m working on intricate spindle work requiring specific centers or turning bowls demanding suitable faceplates, having these diverse options at my disposal significantly enhances my ability to complete each project seamlessly.

The Role of High-Quality Equipment in Woodturning Success

Enhanced Results

Using professional woodturning tools and equipment leads to superior outcomes. Precision-engineered tools minimize the risk of tool chatter or catch that can harm the workpiece, resulting in smoother finishes and finer details. This level of precision is difficult to achieve with lower-quality equipment.

Investing in high-quality equipment for woodturning also contributes to increased productivity. With reliable tools, turners can work more efficiently and produce more pieces within a given timeframe. For example, a sharp and well-balanced gouge lets turners remove material quickly without compromising control or precision.

Improved Safety

Using professional-grade woodturning tools prioritizes safety by reducing the likelihood of accidents caused by tool failure. Quality equipment minimizes the chances of unexpected breakage or malfunction during operation, creating a safer working environment for turners.

Moreover, investing in reliable woodturning equipment saves time and money in the long run by reducing maintenance and replacement costs. When using high-quality items, turners spend less time maintaining their tools and more time turning wood into beautiful creations.

Access to top-notch professional woodturning tools significantly impacts my ability to create stunning pieces while ensuring my safety throughout the process.

Conclusion on Selecting the Best Woodturning Tools and Equipment

Having the right tools is non-negotiable in crafting exceptional wood pieces. The quality of the equipment significantly impacts the outcome, from chucks and jaws to specialty cutters and sharpening systems. Investing in advanced lathes and accessories enhances precision and efficiency, culminating in superior craftsmanship. As a professional woodturner, I understand that utilizing high-quality tools elevates the work and streamlines the entire process. Therefore, selecting the best woodturning tools and equipment is paramount for achieving unparalleled results.

Now that you have gained insights into the essential tools and equipment for professional woodturning, it’s time to take action. Explore reputable suppliers, compare product specifications, and make informed decisions based on your needs. Remember, the right tools are the gateway to unlocking your full potential as a wood-turning artisan.

Frequently Asked Questions

What are the essential woodturning tools for professional craftsmanship?

The essential woodturning tools for professional craftsmanship include a roughing gouge, spindle gouge, bowl gouge, skew chisel, parting tool, and a round-nose scraper. These tools are crucial for creating various shapes and finishes on turned wood projects.

How do I choose the suitable chuck and jaw for my lathe?

When choosing a chuck and jaw for your lathe, consider factors such as the size of your lathe spindle, the turning you’ll be doing (spindle or bowl), and the materials you’ll be working with. Make sure to select a chuck that is compatible with your lathe’s specifications.

Why are sharpening systems critical in woodturning?

Specialty cutters and sharpening systems are crucial in maintaining sharp cutting edges on wood-turning tools. Properly sharpened tools ensure cleaner cuts and smoother finishes and reduce the risk of accidents due to dull blades. Investing in quality sharpening systems can significantly improve woodworking outcomes.

What are advanced lathes and accessories for expert turners?

Advanced lathes often feature variable speed controls, larger swing capacities, outboard turning options, digital readouts for precision control, and ergonomic designs. Expert turners may also invest in specialized accessories such as steady rests, live centers with interchangeable tips, indexing wheels, or attachments.

How can I maximize efficiency when purchasing woodturning equipment?

Maximizing efficiency involves selecting suppliers that offer fast shipping options and diverse accessories under one roof. This ensures quick access to necessary equipment without delays while providing a wide range of products to meet specific project requirements.