Table of Contents

Lathe swing is the maximum diameter of the workpiece that can be turned on a lathe. It is determined by the distance from the spindle center to the nearest obstruction, doubled to represent the total diameter capacity.

How to Measure the Lathe Swing

Required Tools

A tape measure or ruler is essential for measuring a lathe swing. Some prefer calipers for precision. Make sure your tools are in good condition.

First, clean the lathe’s surfaces. Dust can affect measurements. I always check my tools before starting; a bent ruler once gave me incorrect readings. Place your tool of choice over the lathe bed and read the measurement from above.

Measurement Steps

The process involves several steps:

- Locate the center of the spindle.

- Extend your measuring tool across to the bed.

- Record this radius measurement.

- Double it to find the entire swing.

Take your time with these steps; accuracy matters most here.

When I first learned to measure the lathe swing, I found that taking my time helped prevent errors and ensured precise results every time.

Common Mistakes

Avoid these mistakes:

- Only zero out calipers before use.

- Measuring only one side and forgetting to double it.

- Ignoring worn-out measuring tapes, which may stretch over time.

I remember failing to zero out my digital caliper, resulting in an entire batch of parts being off by a small but critical amount!

Measurement of Different Types of Lathe Swing

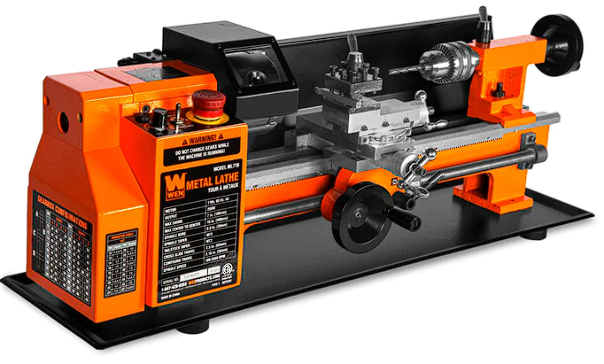

Benchtop Lathes

Benchtop lathes are compact, fitting easily on a workbench. Their swing sizes often range from 3 to 7 inches, making them ideal for small projects like pen-turning or jewelry-making.

I’ve used benchtop lathes for intricate pieces. The smaller swing size allows for precise control, which is crucial in detailed artistry.

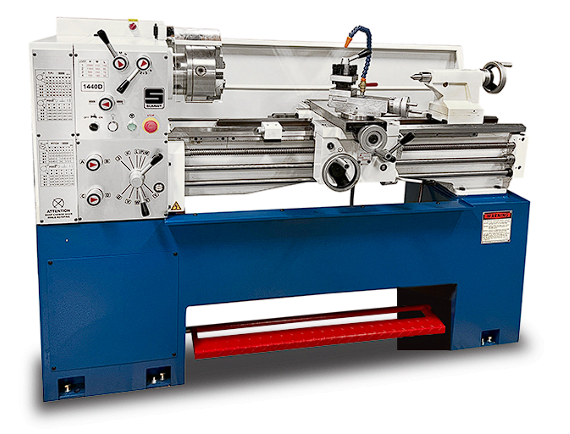

Engine Lathes

Engine lathes are versatile and common in machine shops. They can handle swings from about 13 to over 30 inches, covering various project sizes.

Their robust construction makes it easy to tackle more challenging materials. I appreciate their reliability when working on medium- to large-scale parts.

Toolroom Lathes

Toolroom lathes have similar capacities to engine lathes but focus more on precision and finishing than heavy removal rates. These machines often feature swings between 11 and above inches.

They’re perfect for tasks requiring high accuracy, such as creating fixtures or complex tooling components. In my experience, the finesse these lathes offer is unmatched.

Turret Lathes

Turret lathes stand out because they hold multiple cutting tools at once. This design increases productivity by allowing quick changes between operations without needing tool swaps.

Turret lathes are typically seen in production environments and support various swing dimensions depending on the model. When I need efficiency in repetitive production tasks, I go for a turret lathe because of its multitasking capabilities.

So.. what is a Lathe Swing

Lathe Basics

A lathe swing is the maximum work diameter that can rotate without hitting the lathe bed. It’s measured from the lathe centerline to the closest point on the bed, then doubled. Understanding this term is crucial for selecting a suitable lathe and planning projects.

Most lathes list their swing in specifications. For example, a wood lathe might advertise a “12-inch swing,” which means it handles wood up to 24 inches in diameter. This size influences what you can create.

Machine Functionality

The connection between the lathe swing and machine functionality must be balanced. This measurement dictates what jobs your lathe can handle. An enormous swing allows for bigger workpieces on a wood lathe, like table legs or bowls.

In my experience working with metalworking lathes, knowing your machine’s capabilities ensures efficiency and safety during operation. I’ve learned that attempting to turn an oversized piece risks damaging your project and poses serious safety hazards.

Importance

Understanding your lathe’s swing is essential for several reasons:

- It ensures you choose the correct equipment.

- It helps avoid costly mistakes.

- It enhances workshop safety by preventing accidents due to oversized materials.

I always double-check my material against my tool post clearance when setting up for turning operations to be safe.

Essential Dimensions of a Lathe

Swing Measurement

The swing is the primary dimension when discussing lathes. It determines the maximum diameter workpiece that can be turned on the machine. The swing is double the distance from the center of the spindle to the bed. This means a lathe with a swing of 20 inches can handle materials up to 10 inches in radius.

My experience with different swings taught me that more significant swings offer more versatility but require more space and often cost more. Smaller swings are sufficient for intricate projects like making custom pens or chess pieces.

Spindle Capacity

Next is spindle capacity, which relates directly to swing and length dimensions. The size of bearings in your lathe influences this capacity because they determine how much weight your spindle can support without compromising precision or safety.

I remember working on a project requiring long shafts; my lathe’s spindle bore was too small for these pieces. That day, I learned how crucial it is for drill presses and lathes alike to match their capacities with project requirements.

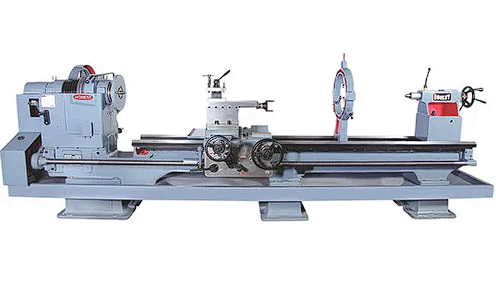

Bed Length

Bed length measures your workpiece’s length while still being supported by your lathe without additional stands or tailstock adjustments. Longer beds allow you to efficiently turn items like table legs or baseball bats.

In my shop, balancing space constraints and desired bed lengths has always been vital in selecting equipment that meets most needs without overcrowding my workspace.

Components of a Lathe and Their Roles

Bed Structure

The bed is the backbone of the lathe. It supports all major parts. Made from rigid material, it ensures stability during operation.

The bed’s alignment directly affects precision. Even slight misalignments can cause significant errors in finished workpieces.

Headstock Assembly

At one end is the headstock. This part holds and rotates the workpiece or material and contains critical components like the spindle, gears, and chuck.

A headstock must be robust enough to handle various speeds without stress. In my experience, a well-maintained headstock results in smoother operations and better-quality parts.

Tailstock Support

Opposite the headstock sits the tailstock. It provides additional support for longer workpieces. It is also used for drilling by holding drill bits firmly against the materials being machined.

Tailstocks are adjustable; they move along the bed to accommodate different-sized pieces. The correct position of tailstocks enhances accuracy significantly when turning long parts on a lathe.

Carriage Mechanism

Below lies the carriage mechanism, which moves cutting tools across the surface of rotating materials. It comprises several components: apron, saddle, compound rest, cross-slide, and tool post. These elements coordinate to shape metals with precision. Their smooth interplay is crucial for achieving desired dimensions on turned parts.

As we’ve touched on in “Key Factors to Consider when Purchasing a Lathe,” a solid grasp of the essential elements of lathes can help buyers make knowledgeable choices.

Notable Features in Modern Lathes

Enhanced Precision

Modern lathes come with advanced features that boost precision. Digital readouts (DROs) are now standard. They show exact measurements on a screen. This means less guesswork and more aThe integration of DROs has transformed my machining work. It allowed me to create parts with tight tolerances, which was more challenging.

Computer numerical control (CNC) technology is another leap forward. CNC lathes can make complex shapes with high precision over and over again.

Efficiency Boosters

Contemporary lathes include features that speed up production. Quick-change tool posts save time when switching between tools like high-speed steel cutters or Morse taper drill bits.

Automatic tool changers are a game-changer for me. They let me step back while the machine swiftly swapped tools. Some machines also have multiple spindles, allowing simultaneous operations.

- Digital readouts

- CNC technology

- Quick-change tool posts

- Automatic tool changers

These elements combined significantly reduce manual adjustments and setup times.

Technology Integration

Technology plays a significant role in improving lathe swings today. For instance, 7x lathes are compact but powerful due to technological advancements. They often feature dovetail slides for smooth tailstock movement and compound rest along the bed’s axis. Moreover, modern materials such as carbide-tipped tools can handle higher speeds without quickly losing their edge. This makes them ideal for milling machine attachments on some lathe models, blending two powerful machine tools into one versatile unit.

Final Tips for Choosing the Right Lathe Based on Swing

Measure Accurately

Before deciding on a lathe, measure the size of the projects you plan to work on. This helps determine the swing you need. Lathes come in various sizes, and their swing dictates how large a material they can handle.

I always check my workspace before buying tools. This ensures enough room for the lathe and safe operation around it.

Key Considerations when Buying a Lathe

Lathe Swing

The lathe swing is a critical factor in choosing a suitable machine. It determines the maximum diameter of work that can rotate over the bed without hitting it. When I consider projects that require turning large diameters, lathe swing size becomes my top priority. More significant swings allow for more versatility but come with higher costs.

A minor swing may be adequate for small-scale projects or limited space. Always match the lathe swing to your most common tasks to avoid overspending on unnecessary capacity.

Budget Constraints

Your budget plays a significant role in selecting a lathe. High-end lathes with advanced features are tempting, but they may not fit within your financial limits. My approach involves balancing costs against essential functions needed for my work.

It is wise to invest more in quality and durability rather than fancy extras you might never use. Before deciding, list must-have features versus nice-to-haves based on your budget.

Project Requirements

Finally, think about your specific project needs when choosing a lathe. The materials you plan to work with and the precision required should influence your decision. Look for lathes with tight tolerance levels and robust construction for intricate pieces requiring high accuracy.

If you’re like me, working on varied projects means needing flexibility from your equipment—consider lathes offering easy changeovers between functions and multiple speed settings for this reason.

Conclusion

Knowing the lathe swing is critical for precision and efficiency in machining. It helps in choosing the suitable lathe for your project and understanding modern features. Review the above info to improve your skills or business. If you need more guidance, it could significantly impact the outcome of your next project.

Frequently Asked Questions

What exactly is a lathe swing?

The lathe swing is the maximum diameter of the workpiece that can be rotated on the machine without hitting the bed. It’s a critical measurement for sizing and capability.

How do you measure a lathe’s swing?

To measure a lathe’s swing, determine the distance from the center of the spindle to the bed and double it. This gives you the maximum material diameter that can turn on that lathe.

Are there different types of lathe swings?

Yes, lathes come with varying swings, typically categorized by size, such as mini, midi, or full-sized lathes, designed for different scales of workpieces.

What critical dimensions should I consider besides swing when choosing a lathe?

Consider both the swing over the bed and the distance between centers. These dimensions impact the size capacity and length of material you can work with.

What should I consider when buying a lathe based on its swing?

Key considerations include the type and scale of planned projects and the available workshop space. Ensure the chosen model accommodates your largest anticipated workpiece size.

Essential components include headstock, tailstock, carriage, and tool post; each plays a vital role in holding and maneuvering tools and workpieces during operations.

What are notable features found in modern lathes relevant to their swings?

Modern lathes may feature digital readouts (DROs), variable speed controls, and more extensive beds for increased capacity—features enhancing precision relative to their specified swings.