Table of Contents

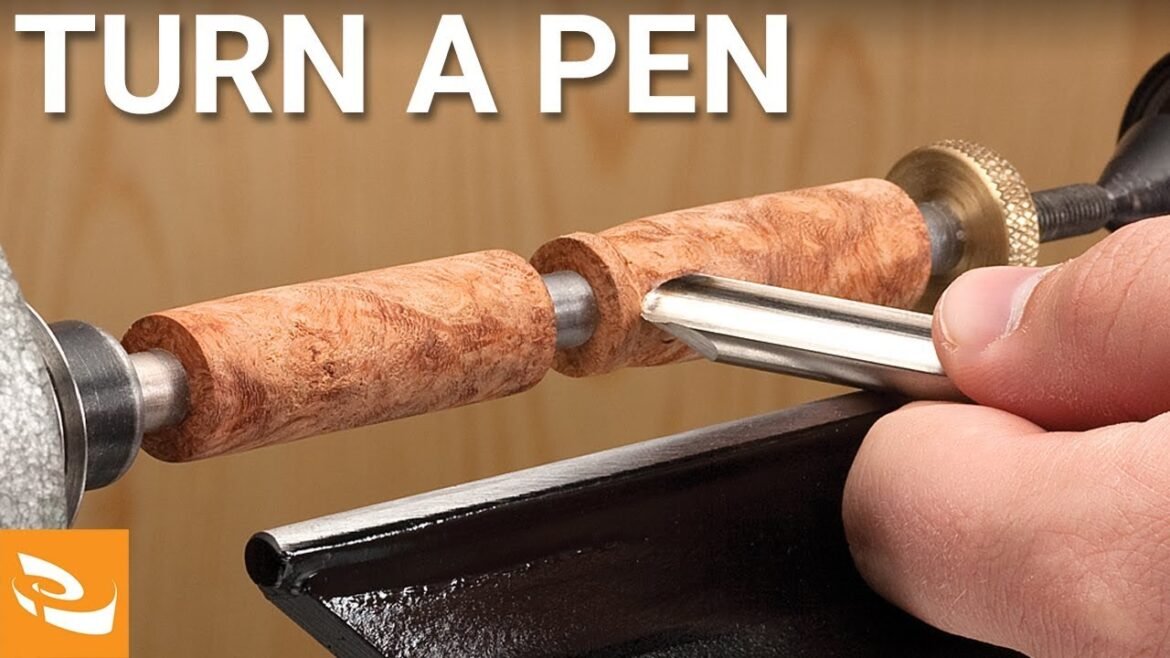

Turning pens on a lathe involves shaping and finishing pen blanks into beautiful writing instruments. This craft requires precision, skill, and the right tools.

Pen turning is a rewarding hobby for woodworkers. It combines creativity and craftsmanship to produce unique, handcrafted pens. Beginners can easily start with basic equipment and materials. Essential tools include a lathe, pen mandrel, chisels, and sandpaper. Selecting high-quality pen blanks ensures better results.

Careful attention to detail during the turning process is crucial. Proper sanding and finishing add the final touches. Safety is important, so always wear protective gear. Pen turning is a satisfying way to create personalized gifts or products to sell. With practice, anyone can master this enjoyable and productive craft.

Credit: www.axminstertools.com

The Art Of Pen Turning

Pen turning started many years ago. People love making things by hand. Handcrafted pens became popular quickly. They are unique and personal. Collectors and artists enjoy them. Pen turning clubs and shows are now common. These events bring people together. They share tips and show their work. This craft keeps growing every year.

Today, pen turning uses modern tools. Lathes are more advanced now. Materials like acrylic and exotic woods are used. This makes pens more beautiful and durable. Online tutorials and guides help beginners. They can learn from experts easily. Kits are available for starters. These kits include all needed parts. This makes starting the hobby easier.

Tools Of The Trade

A mini lathe is perfect for small projects. These lathes are easy to use and save space. They are also more affordable. A midi lathe is a step up. It offers more power and versatility. For bigger projects, a full-size lathe is the best choice. These are heavy-duty machines with more features.

Chisels are a must for shaping the wood. Good chisels make clean cuts. A pen mandrel holds the pen blank steady. It helps in precise turning. Bushings are used to size the pen blank. They ensure the correct fit. Sandpaper smooths the pen after turning. Different grits are needed for a fine finish.

Materials And Preparation

Selecting the right materials and preparation is crucial for turning pens on a lathe. Ensure wood blanks are properly sized and tools are sharpened to achieve a smooth finish.

Selecting Pen Blanks

Choose pen blanks with attractive grain patterns. Common choices are walnut, cherry, and maple. Ensure the blanks are dry and free of defects. Size matters; they should be at least 3/4 inch square and 5 inches long.

Preparing The Wood

Cut the blanks to the desired length. Use a saw for precise cuts. Drill a hole through the center of each blank. This hole will hold the pen tube. Ensure the hole is straight and clean.

Setting Up Your Workspace

Keep your tools within reach. Arrange them neatly on a pegboard. This helps in finding tools quickly. Use labeled drawers for small items. Store wood blanks in a dry place. Ensure your lathe has enough space around it. A clean workspace increases efficiency. Good lighting is also important.

Always wear safety glasses. Protect your ears with earmuffs. Dust masks keep harmful particles away. Use gloves to protect your hands. Avoid loose clothing; it can catch in the lathe. Tie back long hair for safety. Keep a first aid kit nearby. Safety gear is very important.

The Pen Turning Process

First, select a blank for your pen. Secure the blank in a pen vise. Drill a hole through the blank, ensuring it stays straight. Insert a brass tube into the hole, using glue to keep it firm. Trim any excess material from the ends of the blank.

Mount the blank on the lathe using bushings for proper alignment. Use a gouge tool to start shaping the blank. Turn the blank to the desired shape, ensuring smooth and even cuts. Check the diameter frequently to match the bushings.

Start sanding with a coarse grit sandpaper. Gradually move to finer grits for a smoother surface. Apply a finishing polish to enhance the wood’s appearance. Finally, use a wax or resin finish to protect the pen and give it a glossy look.

Customization Techniques

Inlay work makes pens look special. Use different materials to create designs. Wood, metal, and stone work well for inlays. First, cut a groove in the pen blank. Next, fit the inlay material into the groove. Finally, sand it smooth for a seamless finish. This technique adds beauty and uniqueness to your pens.

CA finish makes pens shiny and smooth. Start by sanding the pen blank. Then, apply a thin layer of CA glue. Use a paper towel to spread the glue evenly. Let it dry before adding more layers. Usually, three to four layers work best. After the final layer, sand the pen blank again. Finally, polish it to a high gloss. This finish makes the pen look professional and durable.

Troubleshooting Common Issues

Keep your tools sharp. Dull tools cause chatter. Maintain a steady hand. Avoid pressing too hard on the tool. Use the right speed for your lathe. Slow speed may cause vibrations. Fast speed can prevent chatter. Keep the tool rest close to the wood. This gives better control. Check if the wood is secure. Loose wood can cause tool chatter.

Choose the right wood. Some woods split easily. Avoid dry wood. It splits more. Use a sharp tool. Dull tools can cause splits. Turn the wood slowly. Fast turning may split it. Apply steady pressure. Uneven pressure can cause splits. Seal the wood ends. This helps prevent cracks. Glue small cracks early. This stops them from getting bigger.

Credit: www.pennstateind.com

From Hobby To Business

Create a brand for your pens. Use social media to show your work. Share pictures of your pens. Join craft fairs to sell in person. Talk to local stores about selling your pens. Build a website for online sales. Write a blog about your pen-making journey. Offer custom designs to attract more buyers.

Calculate costs for materials and labor. Add a profit margin to your price. Research competitor prices for similar pens. Consider offering different price ranges. Create special editions for higher prices. Offer discounts for bulk orders. Track sales to adjust prices as needed.

Joining The Community

Discover the joy of turning pens on a lathe by joining our passionate community. Share techniques, get tips, and improve your skills together.

Forums And Social Media

Engage with fellow pen turners online. Many forums offer advice and support. Social media platforms have groups for pen turning. These groups share tips, tricks, and inspiration. Posting your work can get helpful feedback. Meeting others can spark new ideas. Build connections with experienced turners. Ask questions and learn from their knowledge. This makes the hobby more enjoyable.

Workshops And Conventions

Attend workshops to improve your skills. These events have hands-on sessions. Learn new techniques from experts. Conventions are also great for networking. They feature demonstrations and lectures. Meet other pen turners in person. Share your experiences and learn new tips. These events often have vendors. Buy new tools and materials directly from suppliers.

Continuing Your Craft

Mastering advanced techniques helps you create unique pens. Try using different types of wood. Each type offers a unique finish and texture. Practice makes these techniques second nature. Watching tutorials can also help you learn faster. Joining workshops can give you hands-on experience. Don’t hesitate to ask experts for tips. They can offer valuable insights. Developing new skills keeps your craft exciting.

Creating new designs adds flair to your pens. Start by sketching your ideas on paper. Visualizing helps in the actual crafting process. Combine different materials for a unique look. Mixing wood and metal can be eye-catching. Trying out various shapes can make your pens stand out. Keep your creativity flowing by always experimenting. Your unique designs will attract more people.

Credit: www.youtube.com

Frequently Asked Questions

What Speed Do You Turn Pens On A Lathe?

Turn pens on a lathe at speeds between 3,000 and 4,000 RPM. Use sharp tools for smoother finishes.

What Is The Best Lathe For Pen Turning?

The Jet JWL-1221VS is widely regarded as the best lathe for pen turning. It offers variable speed control, stability, and precision. This lathe is perfect for both beginners and experienced pen turners. Its compact size and reliable performance make it a top choice.

Can You Turn Pens On A Big Lathe?

Yes, you can turn pens on a big lathe. Use precise tools and techniques for best results.

What Speed Do You Turn Bowls On A Lathe?

Turn bowls on a lathe at speeds between 500 to 1000 RPM. Adjust based on bowl size and wood type.

Conclusion

Mastering the art of turning pens on a lathe offers immense satisfaction. It combines creativity with craftsmanship. This rewarding hobby not only enhances skills but also produces unique, handmade gifts. Dive in, practice, and enjoy the process. Your efforts will result in beautiful, custom pens that stand out.