Table of Contents

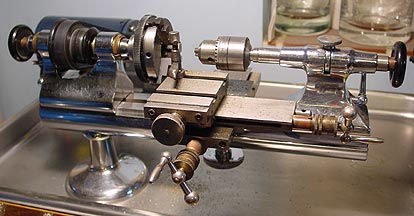

A small metal turning lathe is a versatile tool used for precision machining. It shapes metal by rotating it against cutting tools.

A small metal turning lathe is essential for hobbyists and professionals in metalworking. Compact and efficient, this tool can perform various tasks such as threading, drilling, and facing. Its precision allows users to create intricate designs and components with ease.

The lathe’s adaptability makes it suitable for crafting custom parts, repairing machinery, and creating prototypes. Investing in a small metal turning lathe can significantly enhance your metalworking capabilities. It offers both accuracy and control, ensuring high-quality results in every project. Whether you are a beginner or an experienced machinist, a small metal turning lathe can be a valuable addition to your workshop.

Credit: www.jamesriser.com

Introduction To Small Metal Turning Lathes

Small metal turning lathes are essential tools for metalworking. They shape metal pieces with high precision. These machines are compact and fit in small workshops. Many hobbyists and professionals use them.

Metalworking involves cutting, shaping, and finishing metal. A small lathe can handle these tasks efficiently. It allows users to create detailed parts. It’s perfect for making custom pieces and repairs.

The size of a lathe affects its usability. A small lathe is easier to move and store. It takes up less space in a workshop. These lathes are also more affordable. They are perfect for beginners and small projects.

Credit: eur.vevor.com

Selecting The Right Lathe For Your Projects

Motor power is very important. A strong motor will cut metals easily. Speed control helps for different tasks. Some lathes have variable speed settings. Build quality matters too. A sturdy lathe lasts longer and works better. Size is also crucial. Smaller lathes fit in limited spaces. Precision is key for detailed work. Look for a lathe with high accuracy.

| Brand | Model | Price |

|---|---|---|

| Brand A | Model X | $500 |

| Brand B | Model Y | $750 |

| Brand C | Model Z | $900 |

Setting Up Your Lathe: A Step-by-step Guide

Ensure you have a clean and well-lit workspace. The area should be free from clutter. This helps in avoiding accidents. Keep all your tools organized. This will save time later. Ensure there is enough room around the lathe. This allows for easy movement. Place the lathe on a sturdy bench. It should not wobble or shake.

Level the lathe using a spirit level. This ensures accurate work. Tighten all bolts and screws. This keeps the machine stable. Check the alignment of the tailstock. It should align perfectly with the headstock. Lubricate the moving parts. This reduces wear and tear. Test the lathe by running it at low speed. Ensure everything works smoothly.

Credit: www.amazon.com

Basic Operations And Techniques

A small metal turning lathe performs precise cuts on metal pieces. Sharp cutting tools are essential for clean cuts. Adjusting the lathe speed ensures the best results. Tool angles matter for different materials. Lubrication keeps the process smooth and reduces tool wear. Maintaining a steady feed rate avoids rough edges. Always secure the workpiece tightly. Safety goggles protect your eyes from metal shavings.

Drilling on a lathe requires proper alignment. Center drills help start the hole accurately. Use the tailstock for support during drilling. Threading creates screw threads on metal. Thread cutting tools match the desired thread size. Setting the lathe’s speed and feed rate correctly ensures smooth threads. Lubricants help reduce friction while threading. Always check your work with a thread gauge.

Advanced Crafting Tips

Use a sharp tool for better cuts. Check measurements often for accuracy. Slow down the lathe for fine details. Keep the tool steady and firm. Practice makes perfect.

Choose the right speed for soft metals. Avoid too much pressure to prevent damage. Use a light touch with delicate pieces. Lubricate often to reduce friction. Inspect materials for flaws before starting.

Maintenance And Care For Longevity

Clean your lathe after every use. Remove metal shavings and dust. Use a soft brush to clean. Ensure all moving parts are free from debris. Lubricate the lathe regularly. Apply oil to the gears and bearings. Check for rust and remove it immediately. A well-lubricated lathe lasts longer. Keep a maintenance schedule. Follow the manufacturer’s guidelines.

Lathe not turning? Check the power source first. Ensure all connections are secure. Inspect the motor for any damage. Check for loose belts and tighten them. Facing inconsistent cuts? Verify tool alignment. Ensure the cutting tool is sharp. Examine the spindle for wear and tear. Addressing these issues promptly prevents bigger problems.

Safety Measures And Best Practices

Always wear safety goggles to protect your eyes. Use gloves to keep your hands safe. Ensure your workspace is clean and free from clutter. Keep tools organized and within reach. Proper lighting is essential for safety. Use a face shield to protect from flying debris.

Ear protection is important in noisy environments. Wear sturdy shoes to protect your feet. Ensure ventilation to avoid inhaling harmful fumes. Check that all machines are in good working condition. Emergency exits should always be clear. Know where the fire extinguisher is located.

Never wear loose clothing around machines. Avoid rushing your work to prevent accidents. Double-check your measurements before cutting. Do not use dull tools; they can slip. Always secure your material properly. Keep your focus on the task to avoid mistakes.

Regular maintenance of your lathe is crucial. Use the correct speed settings for each material. Read the manual thoroughly before using any new tool. Do not force the tool; let it do the work. Stay calm and patient while operating machinery.

Expanding Your Skillset

CNC technology can make your work easier. It helps in making precise cuts. CNC machines can follow complex designs. This technology saves time. It also reduces errors. Learning CNC can be fun. You can create amazing projects. Start with simple designs. Gradually move to complex ones. Practice makes you better. Always stay safe. Follow all safety rules. Never rush your work.

Advanced projects challenge your skills. Create unique pieces with your lathe. Try making rings or small statues. Use different metals. Mix creativity with skill. Draw your designs first. Plan each step. Measure twice, cut once. Patience is key. Enjoy the process. Each project makes you better. Keep learning new techniques. Experiment with different tools.

Frequently Asked Questions

What Is The Best Mini Lathe?

The best mini lathe is the Grizzly G8688. It offers precision, durability, and excellent customer reviews. Ideal for hobbyists and professionals.

What Can I Make With A Mini Metal Lathe?

A mini metal lathe can create custom parts like screws, bolts, bushings, and small intricate components. It’s ideal for hobbyists, model makers, and DIY projects. You can also perform tasks like threading, drilling, and facing with precision. This tool suits small-scale manufacturing and repair jobs.

What Is The Smallest Working Lathe?

The smallest working lathe is the Taig Micro Lathe II. It’s compact and ideal for precision tasks. This mini lathe is popular among hobbyists and DIY enthusiasts for its versatility and ease of use.

Can You Turn Steel On A Mini Lathe?

Yes, you can turn steel on a mini lathe. Use proper tooling, low speeds, and lubrication for best results.

Conclusion

A small metal turning lathe can transform your workshop projects. It’s versatile, efficient, and user-friendly. Investing in one enhances precision and creativity. Whether you’re a hobbyist or professional, this tool is a valuable addition. Elevate your craftsmanship with a reliable metal turning lathe.

Your projects will thank you.