Table of Contents

Seasonal maintenance for wood lathes, including regular cleaning of woodturning tools and adapting care routines to changing conditions throughout the year, is crucial for the machine tool’s headstock. In spring, clean off regular accumulated debris and lubricate moving parts to recover from winter storage.

During the summer, focus on dust removal and maintaining excellent, dry conditions to prevent overheating and moisture damage.

In the autumn, check and tighten any loose bolts and threads, and apply rust protectant in preparation for the damp and cold.

Winter requires ensuring the lathe, threads, quill, and banjo are dry and well-covered, ideally stored in a controlled environment to avoid rust and cold damage.

Regularly inspect and replace worn parts each season to ensure your wood lathe’s longevity and optimal performance.

Making Your Wood Lathe Maintenance Checklist

Essential Tasks

Regular seasonal maintenance for wood lathes, including threads and banjo, is crucial to ensure optimal performance and longevity. When creating a maintenance checklist for your wood lathe, include essential tasks that address the specific needs of your wood lathe, such as threads. These tasks typically involve cleaning, lubrication, and inspection.

Cleaning: Regularly clean the lathe bed, tailstock, tool rest, threads, and other components to remove dust, debris, and accumulated residues. This helps prevent wear and tear on threads while ensuring smooth operation. Inspect the motor housing for any buildup that may hinder its functionality, including threads.

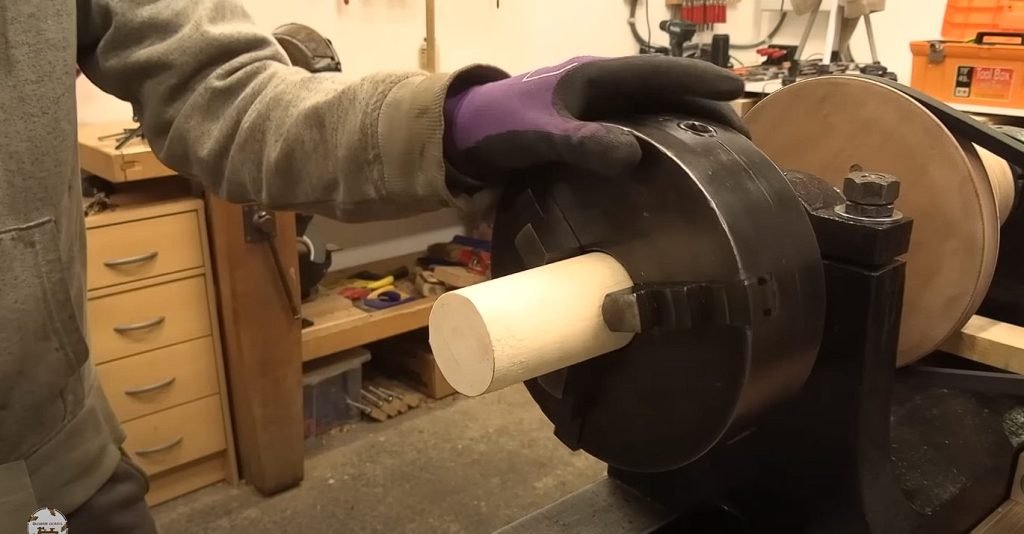

Lubrication: Proper lubrication is vital for reducing friction and preventing premature wear of moving parts. According to the manufacturer’s recommendations, apply lubricant to the spindle bearings, headstock gears, and other moving components.

Inspection: Periodically inspect critical components such as belts, pulleys, screws & nuts for signs of wear or damage. Check for any unusual vibrations or noises during operation, as they can indicate underlying issues that need attention.

Customization Tips

Customizing your maintenance checklist based on your specific lathe model and usage patterns is essential in ensuring comprehensive care tailored to your equipment’s unique requirements. For instance:

- If you frequently work with larger pieces of wood or hardwoods that produce more dust and shavings than usual,

- You may need to increase the frequency of cleaning sessions.

- Likewise, if you use your lathe infrequently,

- It’s essential to perform a thorough inspection before each use due to potentially prolonged periods of inactivity.

shoptop

Daily and Quarterly Wood Lathe Care Routines

Establishing Daily Care Routines

Establish daily care routines to keep your wood lathe in top condition. After each use, start by wiping down the lathe with a clean, dry cloth. This helps remove any dust or wood shavings that could damage the machine. Applying a light coat of wood-specific lubricant to the moving parts can prevent rust and corrosion.

It’s also essential to check for any loose bolts or screws during your daily inspection. Tightening these components ensures the stability and safety of the lathe while in use. Furthermore, inspecting the tool rest and banjo for proper alignment is essential for accurate turning results.

Personal Insight: Dedicating just a few minutes each day to these simple care routines significantly extends the lifespan of my wood lathe.

Implementing Quarterly Maintenance Tasks

In addition to daily care routines, quarterly maintenance tasks are necessary to address deeper cleaning and inspection needs. Begin by thoroughly cleaning all exposed surfaces with a damp cloth and mild detergent solution. This removes built-up grime and residue from previous turning projects.

Furthermore, inspecting the motor belt tension is vital during quarterly maintenance. Over time, belts can stretch or wear out, affecting performance. Adjust or replace as needed to ensure smooth operation of the lathe.

Finally, don’t overlook checking electrical connections for signs of wear or damage during quarterly maintenance sessions. Ensuring secure connections prevents potential hazards when operating the machine.

Properly maintaining your wood lathe regularly prolongs its lifespan and enhances its overall performance.

Essential Areas for Thorough Wood Lathe Upkeep

Cleaning and Lubricating

To ensure seasonal maintenance for wood lathes, it’s crucial to focus on cleaning and lubricating. Regularly remove wood shavings and dust buildup from the headstock, tailstock, and tool rest. Use a brush or vacuum to clear these areas thoroughly.

Lubricate the moving parts with appropriate oil or grease to prevent rusting and ensure smooth operation. Apply a thin lubricant layer to the headstock spindle, tailstock quill, and bedways. This will protect these components from wear and tear while maintaining their functionality.

A soft cloth dipped in mineral oil effectively wipes down metal surfaces without leaving any residue.

Protecting Vital Components

In addition to cleaning and lubricating, protecting vital components is essential for woodturning tools’ longevity. Consider using covers for the headstock, tailstock, and tool rest when not in use. This shields them from dust accumulation, which can affect their precision over time.

Applying a light coat of wax on the metal parts provides an extra layer of protection against moisture and corrosion. Be sure to remove any accumulated wood debris before applying wax, as this can cause scratches during the application process.

When not using my lathe regularly, I cover it with a breathable fabric specifically designed for woodworking equipment.

Rust Removal and Proper Lubrication Techniques

Effective Rust Removal

Use steel wool to scrub the affected areas to remove rust from your wood lathe effectively. Afterward, a flat metal file will smooth out any remaining rough spots. Wipe the surface with a lint-free cloth once the rust is removed.

It’s important to note that regular maintenance can prevent excessive rust buildup on your wood lathe. Applying paste wax on metal surfaces creates a protective barrier against moisture and prevents friction-induced corrosion. Dry silicone spray on moving parts helps repel moisture and inhibits rust formation.

Choosing the Right Lubricants

Consider using oil-based lubricants for nuts, bolts, and other threaded components. For flat metal surfaces prone to wear and tear, applying paste wax effectively reduces friction.

Properly lubricating your wood lathe prevents rust while ensuring smooth operation. Using the correct lubricant reduces wear on moving parts and significantly extends their lifespan. Regular application of suitable lubricants helps maintain optimal performance and protects against corrosion.

Inspection and Adjustment Strategies for Peak Performance

Thorough Component Inspection

When inspecting your wood lathe, developing strategies for a comprehensive check is crucial. Look out for any signs of wear or buildup that could affect the machine’s optimal performance. Check the bed, edges, and threads for any irregularities that might impact the quality of work.

It’s essential to pay close attention to the alignment and ensure all components are in proper contact. You can make necessary adjustments promptly by identifying common issues such as taper or chips on the bed. This thorough inspection process allows you to address potential problems before they escalate.

I find it helpful to create a checklist with specific points for inspection, including areas prone to wear and tear over time. This systematic approach ensures that no critical component is overlooked during inspection.

Fine-Tuning for Optimal Performance

After identifying any issues during the inspection, making adjustments for optimal performance is essential. Fine-tune the belt tension to ensure smooth operation at different speeds. Proper adjustment of power transmission elements contributes significantly to maintaining high-quality work output.

One effective strategy is monitoring and adjusting belt tension based on usage patterns and load variations. Ensuring precise component alignment minimizes vibration and enhances overall stability during operation.

Personal tip: I always note any adjustments made and their impact on performance. This helps me track changes and understand how different settings influence my wood lathe’s operations.

Preventive Maintenance and Proper Storage Solutions

Importance of Preventive Maintenance

Regular maintenance is crucial for extending the lifespan of your wood lathe. Routine cleaning and inspection can identify potential issues early on. This allows you to address them promptly, preventing further damage to the machine. Neglecting this aspect can lead to more severe problems down the line.

Proper care involves using appropriate tools, such as a vacuum or compressed air, to remove dust and debris from critical parts. A protective spray or solution can also help shield metal components from moisture and rust. Inspecting the bed rails for wear and tear is essential in maintaining optimal performance.

Personal tip: I always clean my lathe thoroughly after each use to prevent the accumulation of dust or residue that could potentially cause issues later on.

Tips for Proper Storage

When your wood lathe is not in use, storing it correctly is equally important. One effective method is covering it with a breathable cloth to protect it from dust while allowing airflow. Another approach involves desiccant packs or placing a dehumidifier nearby to mitigate moisture-related risks.

To safeguard against potential damage during extended periods of non-use, consider applying a light coat of oil on exposed metal surfaces. This helps create a barrier against corrosion caused by humidity in the air.

Regular Servicing Frequency and Overall Mechanical System Checks

Determining Maintenance Frequency

Establish a regular cleaning and maintenance schedule to keep your wood lathe in top condition. The ideal frequency for servicing your wood lathe depends on how often you use it and the recommendations provided in the manual. For instance, if you frequently work with hardwoods or dense materials, more frequent maintenance may be necessary to prevent premature wear.

Understanding the manufacturer’s guidelines is essential for ensuring your wood lathe remains in optimal working order. Adhering to these recommendations can mitigate potential issues caused by neglect or improper care. If there are no specific guidelines from the manufacturer, a general rule of thumb is to conduct maintenance at least once a month.

Personal insight: I find that scheduling regular monthly checks helps me avoid potential problems with my wood lathe. Knowing that I’m taking proactive steps to maintain its performance gives me peace of mind.

Importance of Mechanical System Checks

Regular mechanical system checks are vital for identifying signs of wear and tear before they escalate into more significant issues. Inspecting components such as the electric motor, carriage, and other moving parts ensures smooth operation and prevents unexpected breakdowns during use. By routinely examining these elements, you can address any abnormalities promptly.

When conducting system checks, pay close attention to accumulated debris or dust within the machine. If left unattended, these contaminants can affect performance. Clearing out any debris not only prolongs the life of your wood lathe but also contributes to safer operating conditions.

Importance of Wood Lathe Maintenance

Performance Impact

Proper seasonal maintenance for wood lathes is crucial for ensuring optimal performance. Regular cleaning and lubrication of the components help prevent wear and tear, maintaining smooth operation. Neglecting maintenance can lead to decreased precision in turning wood, affecting the quality of your work.

Regular care also ensures that all parts function correctly, reducing the risk of malfunctions during use. This means fewer interruptions and smoother workflow when working on your woodworking projects. For example, keeping the lathe’s bed clean prevents sawdust buildup that could affect the movement of the tailstock or tool rest.

Lifespan Extension

Routine maintenance significantly extends the lifespan of a wood lathe. By regularly inspecting and tightening bolts and checking for any signs of damage or wear, you can prevent major breakdowns or damage to critical parts over time. It’s like giving your lathe a longer lease on life by taking preventive measures against potential issues.

Moreover, proper storage practices during periods of non-use (such as winter) contribute to preserving its condition over time. Storing it in a dry place with minimal temperature fluctuations helps prevent rust and corrosion, which can occur if exposed to moisture-laden environments.

Conclusion: Ensuring the Longevity of Your Wood Lathe

Make a checklist for daily, quarterly, and seasonal care to keep your wood lathe working well and lasting longer. This includes preventing rust, lubricating correctly, and checking and adjusting everything. Remember to prioritize preventive maintenance, proper storage, regular servicing, and mechanical system checks. Taking care of your wood lathe will improve your woodworking and save you money on repairs or replacements.

Follow these maintenance practices to ensure your wood lathe lasts a long time. Regular upkeep will improve your woodworking and keep your equipment in good shape. Start caring for your wood lathe today for smooth operations and great woodworking results.

Frequently Asked Questions

What is the importance of seasonal maintenance for wood lathes?

Seasonal maintenance is crucial for wood lathes to prevent wear, ensure precision, and maintain safety. It helps identify potential issues early, preserve the machine’s longevity, and provide high-quality woodworking output.

How often should I lubricate my wood lathe?

Lubrication frequency depends on usage, but generally, it’s recommended to lubricate your wood lathe every 40-60 hours. Use a high-quality lubricant suitable for woodworking machinery and follow manufacturer guidelines for best results.

What are the essential areas to focus on during wood lathe maintenance?

Key areas include the spindle and bearings, tool rest assembly, tailstock alignment, motor and pulleys, drive belts or chains, banjo, and tool post locks. Regular inspection and upkeep of these components are vital for optimal performance.

How can I effectively remove rust from my wood lathe?

Use fine-grade steel wool or abrasive pads and a rust remover solution to remove rust from a wood lathe. After removing the rust, thoroughly clean and dry the surfaces before applying a protective coating like wax or oil to prevent future corrosion.

Why is preventive maintenance necessary for wood lathes?

Preventive maintenance helps detect potential problems early on, preventing costly repairs later. It also ensures consistent performance while extending the lifespan of your wood lathe equipment.