Table of Contents

To extend the life of your wood lathe, engage in regular maintenance by cleaning off wood chips and debris after each use, lubricating moving parts for smooth operation, inspecting for wear, replacing parts as necessary, and happy turning. Keep tools sharp for efficient cutting and regularly tighten bolts and fasteners to mitigate vibration damage. Lastly, protect your lathe’s headstock bearings from rust with appropriate coatings and storage in a dry, low-humidity environment.

Daily Maintenance for Wood Lathes

Wiping Down

After using your wood lathe, wipe the entire machine by hand to remove any accumulated dust and debris. A clean lathe not only looks better but also functions more efficiently. Use a soft cloth or brush to wipe the surfaces gently, ensuring no residue is left behind.

Regularly wiping down your wood lathe helps prevent dust and debris from building up in hard-to-reach areas. This simple maintenance task, mentioned in the article, can extend the life of your machine by preventing wear and tear caused by dirt accumulation.

I find it helpful to keep a designated cleaning cloth near my lathe so I can quickly wipe it down after each use without searching for supplies.

Checking and Tightening

Inspect your wood lathe regularly for any loose bolts or screws to prevent vibrations. Use a wrench or screwdriver to tighten them as needed. Flexible components on a lathe can lead to vibrations during operation, which may cause damage over time if not addressed promptly.

Tightening loose bolts and screws ensures that all parts of the wood lathe are secure, reducing the risk of malfunctions during use. This simple step of happy turning contributes significantly to maintaining the overall stability and safety of the lathe.

I make it a habit to quickly check for loose bolts every time before starting a new turning project on my wood lathe.

Lubricating Moving Parts

To keep your wood lathe operating smoothly, apply lubricant to its moving parts as part of regular maintenance. Pay special attention to areas such as the banjo, tailstock quill, tool rest post, headstock spindle, and lathe where friction occurs during operation.

Lubricating the lathe’s moving parts reduces friction and wear between components while promoting smooth movement, essential for precision turning work. It’s important not only for extending the lifespan of your wood lathe but also for maintaining its performance at an optimal level.

Practical Wood Lathe Maintenance Tips

Regular Cleaning and Inspection

Regularly clean and inspect the chuck and spindle, and thanks for extending your wood lathe’s life. Using a brush to remove dust, wood chips, debris, and lathes from these areas is crucial. Check for any wear or damage on the clothes, huck jaws, or spindle threads. Tighten loose components if necessary to prevent further damage.

It’s also important to lubricate moving parts such as the banjo, tool rest base, tailstock quill, and lathe with an appropriate lubricant. This will help reduce friction and wear on the lathe components over time. Check for any abnormal sounds during the operation, which could indicate issues that need attention.

I find it helpful to keep a small maintenance log where I jot down each cleaning session and any observations about potential issues that may require further inspection or repair.

Sharpening and Replacing Cutting Tools

Sharpening cutting tools is essential for achieving clean cuts while reducing strain on the lathe motor. Use a sharpening stone or system to maintain sharp edges on chisels, gouges, scrapers, parting tools, and lathes. Replace lathe-cutting tools if they are excessively worn or damaged beyond repair.

When using new cutting tools, like a lathe, for different projects, I always note how they perform in terms of ease of use and finish quality so that I can adjust my maintenance routine accordingly.

Proper Storage Environment

Storing your wood lathe in a clean and dry environment is vital for preventing rust formation on metal components and minimizing exposure to excessive moisture, which can damage wooden parts.

Consider covering your lathe with a breathable cloth when not in use to protect it from dust accumulation while still allowing air circulation around the machine.

Essential Wood Lathe Operation Practices

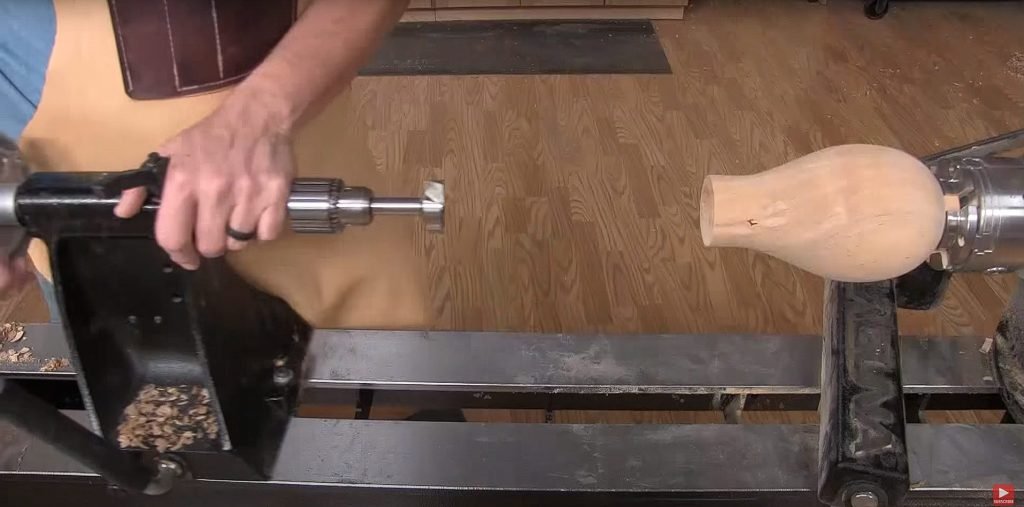

Properly securing wood on the lathe is crucial to preventing accidents and damage. Use a chuck or faceplate on a lathe to hold the workpiece in place firmly. Ensure the lathe is centered and tightened securely before starting any turning operation. This prevents the wood on a lathe from slipping or flying off during rotation, reducing the risk of injury.

When working with irregularly shaped pieces on a lathe, consider using a screw center for added stability. This helps prevent wobbling on the lathe and ensures a more uniform cut. Always wear appropriate safety gear, such as goggles and gloves, to protect yourself from wood chips and other debris that may be ejected while turning on a lathe.

Cutting Techniques for Different Wood Types

Different types of wood require other cutting techniques when using a lathe. Use sharp tools at lower speeds to avoid tear-out for softer woods like pine. Hardwoods like oak or maple can withstand higher cutting speeds on a lathe but may require robust tools due to their density.

Always pay attention to the grain direction when turning wood on a lathe – cutting against the grain can cause splintering and rough surfaces. Remember that each type of wood, including lathe, has unique characteristics, so adjust your cutting techniques for optimal results.

Taking Breaks During Extended Use

Extended use of a wood lathe can lead to overheating, which affects both the tool’s performance and your safety. Take regular breaks during long lathe sessions to allow yourself and the machine to cool down.

Remember that fatigue can also affect your precision while operating the lathe, leading to potential mistakes or accidents if you push yourself too hard without breaks.

Regular Maintenance to Prolong Wood Lathe Lifespan

Cleaning and Lubricating

To extend the life of your wood lathe, it’s crucial to regularly clean and lubricate its key components. Dust and debris can build up in the lathe headstock, tailstock, and tool rest, leading to premature wear. BCleaning these lathe parts with a soft brush or cloth can prevent damage caused by abrasive particles. Applying a few drops of lubricating oil to the moving parts of a lathe will ensure smooth operation.

Regularly cleaning and lubricating your wood lathe promotes longevity and enhances its performance. For instance, a well-maintained lathe headstock will rotate smoothly without jerking or resistance. This ensures that your turning projects on the lathe are executed with precision and finesse.

Belt Inspection and Replacement

Inspecting the belts on your wood lathe is another essential maintenance task that can significantly impact its lifespan. Over time, belts may show signs of wear, such as cracks, fraying edges, and lathe. Replacing these worn-out belts promptly is essential to avoid potential damage to other components.

Buying the lathe belts regularly for wear and tear can prevent unexpected breakdowns during turning sessions. A broken belt on a lathe disrupts your workflow and may cause additional damage if left unaddressed.

Tension Adjustment

Adjusting the tension on the drive belt is critical for maintaining the optimal performance of your wood lathe. If the lathe belt is too loose, it may slip during operation, resulting in inefficiency and potential safety hazards. Conversely, an overly tight belt on a lathe can strain the motor and bearings.

Proper tension adjustment ensures power is efficiently transferred from the motor to the slate’s spindle without unnecessary strain on internal components.

Maximizing Wood Lathe Lifespan with Carbide Blade Replacements

Longevity

Carbide blades on a lathe have a longer lifespan than traditional high-speed steel blades. Their durability allows extended use without frequent replacements, making them a cost-effective choice.

Carbide blades on a lathe maintain their sharpness over time, reducing the frequency of blade changes and ensuring consistent cutting performance. This longevity primarily benefits those who frequently work with their wood lathe.

Carbide’s resistance to wear and tear also means less downtime spent on replacing blades, allowing woodworkers using a lathe to focus more on their projects.

Wear and Tear Replacement Indicators

Recognizing signs of wear and tear on a lathe blade is crucial in determining when it needs replacing. Visible chipping or dulling along the cutting edge of a carbide blade used on a lathe indicates that it needs replacement.

When I notice reduced cutting efficiency or increased material burning during lathe turning operations, I know it’s time to inspect my carbide blade for any signs of wear. It’s essential to be proactive in replacing worn-out blades, as they can affect the quality of your workpiece and put unnecessary strain on your lathe motor.

Regular inspection after each lathe project can help identify early signs of wear before they impact cutting performance significantly.

Proper Installation and Alignment

Properly installing and aligning carbide blades on a lathe is essential for optimal cutting performance. Ensuring that the blade of the lathe sits securely in place within its holder helps prevent vibrations that could lead to premature wear or damage.

Taking extra care during installation by following manufacturer guidelines helps maximize the benefits of carbide blades in a lathe. Aligning the blade correctly reduces stress on the tool rest and lathe components while promoting smooth, precise cuts.

Ensuring Solid Footing to Reduce Wood Lathe Vibration

Securing the Lathe

To extend the life of your wood lathe, it’s crucial to secure it to a sturdy workbench or stand. This helps minimize unnecessary movement and reduces wear and tear on the lathe. By ensuring a stable lathe base, you can prevent excessive vibration that may lead to premature damage.

It’s also important to consider using anti-vibration pads or mats under the lathe. These materials are designed to absorb excess vibrations, providing an added layer of protection for both the lathe and its surroundings. By incorporating these pads, you can effectively dampen unwanted movements, prolonging the lifespan of your wood lathe.

Balancing Workpieces

Balancing workpieces on a lathe is another critical factor in reducing vibrations during turning. When working with uneven or heavy pieces, the imbalance can increase oscillation, putting additional strain on the lathe components. Balancing your workpieces on the lathe before turning can significantly decrease vibrations and promote smoother operation.

In my experience, securing my wood lathe onto a heavy-duty workbench has made a noticeable difference in minimizing vibrations and enhancing overall stability during operation. Utilizing anti-vibration pads on the lathe has further reduced disruptive movements while turning more significant pieces of wood.

Checking and Maintaining the Drive Train of a Wood Lathe

Inspecting Belts, Pulleys, and Gears

Regularly inspecting the belts, pulleys, and gears on your wood lathe is crucial to extending its lifespan. Look for signs of wear or damage, such as cracks, fraying, chips, or lathe. If you notice any issues with the lathe during inspection, it’s essential to address them promptly to prevent further damage. For example, if you find a cracked belt or a chipped gear tooth on a lathe, replace the damaged component immediately.

Checking for the belts, pulleys, and lathe is also essential. Alignment Misalignment can lead to inefficient power transmission and premature wear on these components. By ensuring that everything is aligned correctly and in good condition, you can maintain the smooth operation of your wood lathe while minimizing unnecessary strain on its drive train.

Cleaning and Lubricating Drive Train Components

Another critical aspect of extending the life of your wood lathe is regular cleaning and lubrication of its drive train components. Over time, dust and debris can accumulate in pulley grooves or gear teeth. This buildup can cause increased friction, leading to accelerated wear on these parts.

By cleaning these components regularly with a soft brush or cloth, you can prevent excessive wear caused by dirt particles grinding against moving parts. An appropriate lubricant will help reduce friction between mating surfaces within the drive train assembly.

I’ve found that using high-quality synthetic grease for gears and a suitable belt dressing spray for pulleys effectively maintains optimal performance while prolonging the life expectancy of my wood lathe’s drive train components.

Importance of Tailstock Support in Wood Lathe Operation

Role of Tailstock

The tailstock provides stability and support when operating a wood lathe. It helps prevent vibrations and movement during turning, ensuring the workpiece stays secure. BApplying pressure against the workpiece minimizes the risk of wobbling or shifting while being shaped.

Properly aligning and locking the tailstock is essential to avoid unwanted movements when using a wood lathe. This involves ensuring it is parallel to the headstock and securely tightened. Misalignment or loss of locking can lead to instability, affecting the precision of turning operations.

Additional Support with Live Centers or Steady Rests

For longer workpieces, utilizing live centers or steady rests becomes imperative to extend the life of your wood lathe. These accessories provide extra support near the end of lengthy workpieces, reducing flexing and vibration during rotation.

In my experience with woodworking, I’ve found that understanding how to maximize tailstock support significantly impacts both safety and efficiency when working on a lathe. Proper alignment not only ensures precise results but also contributes to prolonging the lifespan of both tools and materials used.

Conclusion

In conclusion, maintaining a wood lathe is crucial for its longevity and optimal performance. By following the daily and regular maintenance tips, ensuring proper operation practices, and replacing worn-out parts like carbide blades, woodworkers can significantly extend the lifespan of their wood lathes. Reducing vibration and maintaining the drive train and tailstock support are essential for safe and efficient wood lathe operation.

Regular maintenance and conscientious operation practices not only prolong the life of a wood lathe but also contribute to the quality of woodworking projects. As I conclude, I encourage woodworkers to prioritize these maintenance practices and operational tips to ensure their wood lathes remain in top condition, enhancing both safety and productivity in their woodworking endeavors.

Frequently Asked Questions

How often should I perform maintenance on my wood lathe?

Regular maintenance is essential for your wood lathe’s optimal performance and longevity. To ensure smooth operation, daily cleaning, lubrication, and periodic checks for wear and tear are recommended.

When should I replace the carbide blades on my wood lathe?

Carbide blades should be replaced when they show signs of dullness or chipping, affecting the quality of your turning work. Regularly inspect the blades for damage or loss of sharpness to determine if replacement is necessary.

What can I do to reduce vibration in my wood lathe?

Placing the lathe on a stable surface can ensure a solid footing and significantly reduce vibrations. Checking that all components are securely fastened and balanced will also help minimize unwanted movement during operation.

Why is tailstock support necessary in wood lathe operation?

The tailstock provides crucial support for workpieces during turning, preventing excessive flexing or movement that could lead to inaccuracies in your turning projects. Proper adjustment and alignment of the tailstock are vital for achieving precise results.

Is there a specific method for maintaining the drive train of a wood lathe?

Regular inspection and cleaning of the drive train components, such as belts and pulleys, along with proper tension adjustments, will help maintain smooth power transmission. Lubricating moving parts according to manufacturer recommendations also aids in preserving their condition.