Table of Contents

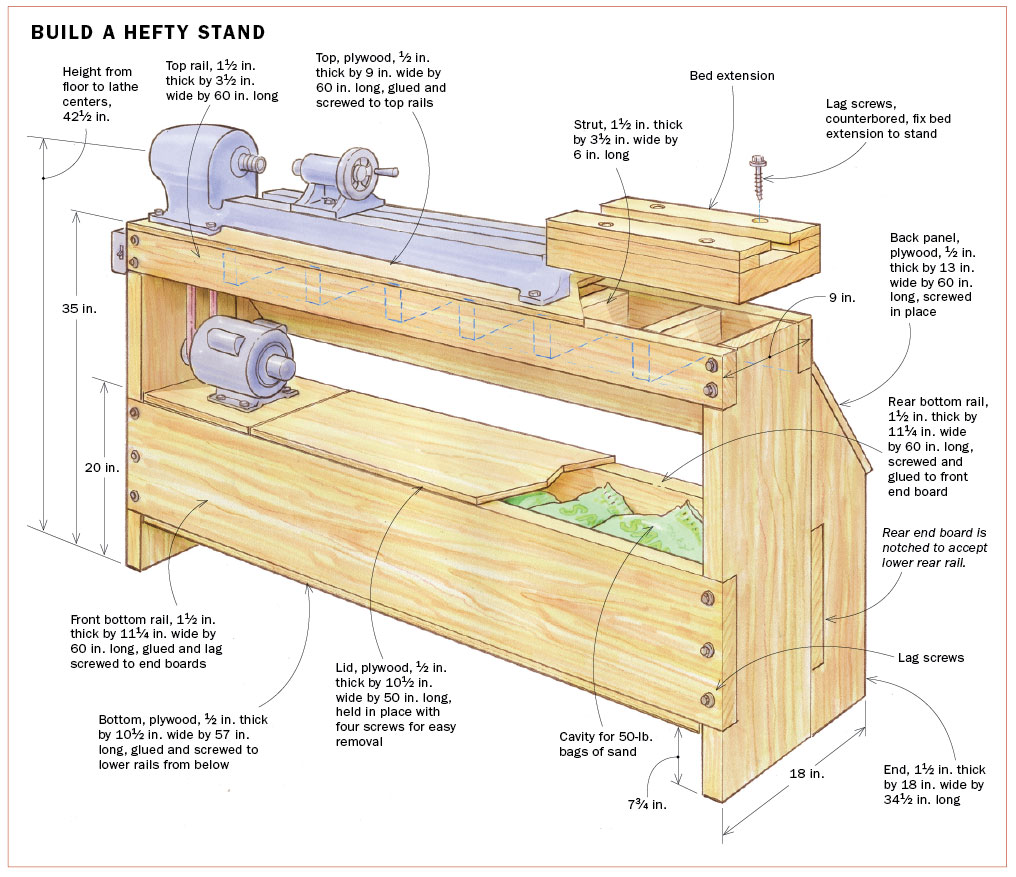

A wood turning lathe stand provides stability and support for your lathe. It ensures precision and safety during woodturning tasks.

A wood turning lathe stand is essential for any woodworker. It offers a sturdy base, which is crucial for maintaining balance and accuracy. The stand minimizes vibrations, allowing for smoother operation and better results. Many stands come with adjustable heights, catering to different user preferences and ergonomic needs.

Materials like steel and cast iron are popular for their durability and strength. Investing in a quality stand enhances your woodworking experience and prolongs the life of your lathe. Whether you’re a hobbyist or a professional, a reliable lathe stand is a valuable addition to your workshop.

Credit: www.finewoodworking.com

Introduction To Wood Turning Lathes

Wood turning lathes are vital for creating round wooden objects. They make bowls, spindles, and furniture legs. A lathe spins the wood while you shape it with tools. This tool is essential for many woodworking projects.

The Role Of A Lathe Stand

A lathe stand holds the lathe steady. It prevents vibrations and movements during work. This ensures precise and smooth cuts. A solid stand is crucial for safety and accuracy.

Lathe stands come in various sizes and materials. Some are made of metal, others of wood. The stand must match the lathe’s size and weight. A good stand keeps your lathe at the right height. This helps in reducing strain and fatigue.

Benefits Of A Custom Stand

A custom stand offers many advantages. It fits your specific needs and space. Custom stands are often sturdier and more durable. They provide extra storage for tools and accessories.

Here are some benefits of a custom stand:

- Stability: Custom stands can be tailored for maximum stability.

- Comfort: Adjust the height to suit your working posture.

- Storage: Add shelves or drawers for easy access to tools.

- Durability: Choose high-quality materials for a longer lifespan.

| Feature | Benefit |

|---|---|

| Stability | Prevents vibrations, ensures smooth cuts |

| Comfort | Reduces strain and fatigue |

| Storage | Keeps tools and accessories organized |

| Durability | Long-lasting and reliable |

Design Criteria For The Ideal Lathe Stand

Creating the ideal lathe stand requires careful consideration. It must meet specific design criteria to ensure the best performance. Two crucial aspects are ergonomics and comfort and stability and vibration reduction.

Ergonomics And Comfort

A well-designed lathe stand should prioritize ergonomics and comfort. The stand height should be adjustable to suit different users. This prevents strain and enhances precision. The workspace should be clear and free from obstructions, allowing easy movement.

Consider adding a footrest to reduce fatigue. The controls should be within easy reach. Ensure the stand has a smooth surface to avoid injuries. Comfortable working conditions lead to better craftsmanship and productivity.

Stability And Vibration Reduction

The lathe stand must be stable to ensure safety. A sturdy base prevents wobbling during operation. Use heavy-duty materials like steel or hardwood. These materials provide excellent support and durability.

Vibration reduction is vital for precise work. Incorporate anti-vibration pads or feet in the design. These components absorb shocks and reduce noise. Ensure the stand is level and properly balanced.

| Design Aspect | Considerations |

|---|---|

| Height | Adjustable for different users |

| Workspace | Clear and free from obstructions |

| Footrest | Reduces fatigue |

| Controls | Within easy reach |

| Surface | Smooth to avoid injuries |

| Base | Sturdy to prevent wobbling |

| Materials | Heavy-duty like steel or hardwood |

| Anti-vibration pads | Absorb shocks and reduce noise |

| Balance | Level and properly balanced |

Materials For Building A Lathe Stand

Choosing the right materials is crucial for building a sturdy lathe stand. The right materials ensure durability and stability. Below, we explore the best options for your lathe stand.

Wood Vs. Metal Stands

Both wood and metal have their own advantages. Understanding their differences helps in making an informed decision.

| Material | Advantages | Disadvantages |

|---|---|---|

| Wood |

|

|

| Metal |

|

|

Choosing The Right Wood

Choosing the right wood for your lathe stand ensures stability and durability. Different types of wood offer unique benefits.

- Oak: Strong and durable. Ideal for heavy-duty stands.

- Maple: Hard and resistant to wear. Good for long-term use.

- Pine: Lightweight and easy to work with. Not as strong as hardwoods.

Use hardwoods for the base and legs. Softwoods can be used for less critical parts. Ensure the wood is dry and free from defects.

Planning Your Lathe Stand

Planning your lathe stand is crucial. It ensures a smooth woodworking experience. A well-designed stand offers stability and efficiency.

Dimensions And Workspace Considerations

Consider your workspace size first. Measure the available area for the lathe stand. A compact stand suits small spaces. A larger stand fits bigger workshops.

| Workspace Size | Recommended Stand Size |

|---|---|

| Small (up to 100 sq ft) | Compact Stand (2-3 ft long) |

| Medium (100-250 sq ft) | Standard Stand (3-4 ft long) |

| Large (250+ sq ft) | Large Stand (4-6 ft long) |

Ensure the stand height fits your working posture. This helps reduce fatigue. The stand should be sturdy to avoid vibrations. Stability is key for precision work.

Tool And Accessory Storage

Good storage keeps your tools handy. Plan for drawers or shelves. They help organize chisels, gouges, and other tools.

- Drawers for small tools

- Shelves for larger items

- Hooks for hanging accessories

Consider a pegboard for easy access. A pegboard allows quick tool changes. Keep your workspace tidy and efficient.

Label storage areas clearly. This saves time searching for tools. An organized stand boosts productivity.

Assembly Tips And Techniques

Assembling a wood turning lathe stand requires precision and care. Following expert tips will ensure a sturdy and reliable setup. This guide covers essential techniques for joinery and securing your lathe to the stand.

Joinery For Durability

Using strong joinery techniques is crucial for a durable lathe stand. Consider using mortise and tenon joints for maximum strength. These joints interlock and provide robust support.

- Mortise and Tenon: Perfect for heavy-duty stands.

- Dovetail Joints: Adds aesthetic appeal and strength.

- Box Joints: Simple yet effective for light to medium tasks.

Ensure all joints are properly glued and clamped until fully dry. This ensures they hold under stress.

Securing The Lathe To The Stand

Properly securing the lathe is crucial for safety and performance. Use heavy-duty bolts to attach the lathe to the stand.

- Position the lathe on the stand.

- Mark the bolt holes on the stand.

- Drill the holes and insert bolts.

- Tighten the bolts securely.

Use lock washers to prevent the bolts from loosening over time. This step is essential for long-term stability.

For extra stability, consider adding cross-bracing to the stand. This can be done with steel or wood braces, and it will reduce any wobbling.

Credit: m.youtube.com

Finishing Touches For Aesthetics And Protection

Adding the final touches to your wood turning lathe stand can make a big difference. A well-finished stand not only looks good but also lasts longer. Let’s explore how to seal and protect the wood, and add personal touches.

Sealing And Protecting The Wood

Sealing the wood helps in maintaining its quality over time. It prevents moisture and dust from damaging your stand.

- Use Wood Sealer: Apply a coat of wood sealer for protection.

- Sand Smooth: Sand the surface to ensure it’s smooth before sealing.

- Apply Varnish: A varnish adds a shiny finish and additional protection.

Below is a simple table outlining the steps to seal and protect your wood:

| Step | Description |

|---|---|

| 1 | Clean the wood surface |

| 2 | Sand the surface to smooth it |

| 3 | Apply a coat of wood sealer |

| 4 | Let it dry completely |

| 5 | Apply varnish for a shiny finish |

Adding Personal Touches

Adding personal touches makes your wood turning lathe stand unique. Here are some ideas to consider:

- Staining: Choose a wood stain that matches your style.

- Engraving: Engrave your initials or a design.

- Painting: Add a splash of color with paint.

Personal touches make your stand one-of-a-kind. They can also reflect your personality and creativity.

Maintenance And Upkeep

Maintaining your wood turning lathe stand is crucial for its longevity. Proper care ensures smooth operation and safety. Follow these tips to keep your stand in top condition.

Regular Inspection And Adjustments

Regular inspection of your lathe stand is essential. Check for any loose bolts or parts. Tighten them as needed to maintain stability. Look for signs of wear and tear. Replace damaged components promptly.

Adjustments are also necessary for optimal performance. Ensure the stand is level. Use a spirit level to check it. Adjust the feet to maintain balance. A balanced stand reduces vibrations and increases accuracy.

Lubrication is another key aspect. Apply oil to moving parts. This prevents rust and ensures smooth movement. Use a clean cloth to wipe off excess oil.

Long-term Care For Your Stand

Long-term care keeps your lathe stand in prime condition. Store the stand in a dry area. Moisture can cause rust and damage. Use a cover to protect it from dust.

Regular cleaning is also vital. Dust and wood chips can accumulate. Use a vacuum or brush to clean the stand. Pay special attention to joints and moving parts.

Inspect the electrical components periodically. Check the wiring for any signs of wear. Replace frayed wires immediately. This ensures safety and prevents accidents.

Follow these tips for a well-maintained lathe stand. It will serve you well for years to come.

Credit: m.youtube.com

Case Studies: Successful Lathe Stand Projects

Creating a wood turning lathe stand can be a rewarding project. From amateur woodworkers to seasoned professionals, many have built impressive stands. In this section, we’ll look at some successful lathe stand projects.

Amateur Woodworkers’ Creations

Even beginners can build sturdy and functional lathe stands. Here are some examples:

| Creator | Materials | Features |

|---|---|---|

| John Doe | Pine Wood | Simple design, easy to build |

| Jane Smith | Reclaimed Wood | Eco-friendly, rustic look |

John Doe used pine wood for his stand. It has a simple design. It is easy to build. Jane Smith opted for reclaimed wood. Her stand is eco-friendly. It has a rustic look.

Professional Grade Setups

Professional woodworkers create advanced lathe stands. These stands have special features:

- Heavy-duty construction

- Multiple storage options

- Enhanced stability

Mark Johnson built a stand with heavy-duty construction. It has multiple storage options. It offers enhanced stability. Emily Davis created a stand with metal reinforcements. It is highly durable. It supports large projects.

Whether you’re an amateur or a pro, a custom lathe stand enhances your woodworking experience. These case studies show it’s possible for anyone to succeed.

Frequently Asked Questions

How Tall Should A Wood Lathe Stand Be?

A wood lathe stand should be approximately 40 inches tall. This height ensures comfortable use and reduces strain. Adjust based on personal height and preference.

Should I Bolt My Wood Lathe To The Floor?

Yes, bolting your wood lathe to the floor ensures stability and safety. It reduces vibration and enhances precision.

What Is The Best Height For A Lathe Bench?

The best height for a lathe bench is between 36 to 44 inches. This height ensures comfort and reduces strain. Adjust based on your height for optimal ergonomics. Proper bench height enhances precision and safety.

Why Should You Stand At The Right Height When Using A Lathe?

Standing at the right height ensures safety, precision, and comfort while using a lathe. It prevents strain and enhances control.

Conclusion

Crafting a wood turning lathe stand enhances your woodworking experience. It provides stability and precision for your projects. With the right materials and a solid design, your stand will last for years. Invest in a quality lathe stand to achieve professional results in your woodworking endeavors.

Happy turning!