Table of Contents

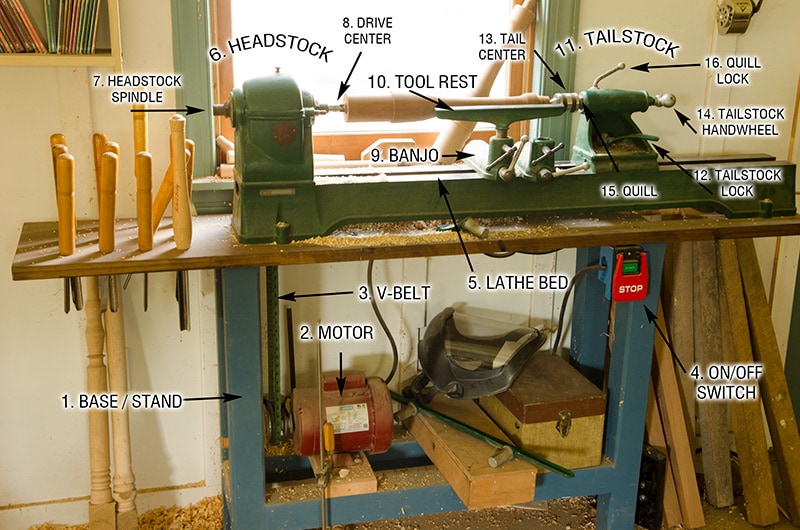

A wood turning lathe machine consists of essential parts such as the headstock, tailstock, bed, and tool rest. These components work together to shape wood accurately.

Wood turning lathe machines are vital in woodworking, allowing artisans to create intricate designs and shapes. The headstock houses the motor and spindle, crucial for rotating the workpiece. The tailstock supports the opposite end, ensuring stability. The bed provides the foundation, connecting all parts securely.

The tool rest assists in guiding the tools, facilitating precise cuts. Understanding these parts is essential for anyone keen on mastering woodturning. Proper maintenance and handling of these components ensure longevity and efficiency, making wood turning both an art and a skill.

Credit: www.pinterest.com

Introduction To Wood Turning Lathe Machines

Wood turning lathe machines are essential tools in woodworking. These machines help shape wood into various forms. They are especially useful for creating cylindrical objects. Wood lathes spin a piece of wood while a tool shapes it. This process is called wood turning. It is both an art and a skill.

The Art Of Wood Turning

Wood turning is a unique form of art. It requires precision and creativity. Craftsmen use wood lathes to create beautiful objects. These can include bowls, vases, and intricate designs. The process starts with a block of wood. The lathe spins the wood at high speeds. The craftsman then uses special tools to carve the shape. Each piece is unique and showcases the artist’s skill.

Primary Uses In Woodworking

Wood turning has many uses in woodworking. It is used to make functional items and decorative pieces. Some common uses include:

- Furniture legs: Many tables and chairs have turned legs.

- Bowls and vases: These are popular items made on a lathe.

- Spindles: Used in staircases and railings.

Wood turning lathes are versatile tools. They are a must-have for any serious woodworker. Below is a table showing the main parts of a wood turning lathe machine:

| Part | Description |

|---|---|

| Headstock | Holds the motor and spindle. |

| Tailstock | Supports the other end of the workpiece. |

| Tool Rest | Supports the cutting tools. |

| Bed | The base of the machine. |

Anatomy Of A Wood Lathe

Understanding the anatomy of a wood lathe helps in achieving precise woodwork. A wood lathe has several crucial parts. Each part plays a unique role in the woodturning process. In this section, we will explore the basic components and structural overview of a wood lathe.

Basic Components

The wood lathe consists of several basic components. Each component has a specific function. Here are the primary parts:

- Headstock: Holds the motor and drives the spindle.

- Tailstock: Supports the other end of the workpiece.

- Bed: The horizontal base connecting the headstock and tailstock.

- Tool Rest: Provides a steady place for tools during operation.

- Spindle: Rotates the workpiece for turning.

- Banjo: Adjusts the position of the tool rest.

Structural Overview

The structure of a wood lathe is designed for stability and precision. Let’s break down its key elements:

| Component | Description |

|---|---|

| Headstock | Contains the motor and controls the spindle. |

| Tailstock | Adjustable and supports the workpiece’s end. |

| Tool Rest | Allows for stable tool placement during turning. |

| Bed | The foundation connecting headstock and tailstock. |

| Spindle | Rotates to shape the wood piece. |

| Banjo | Adjusts the tool rest for better control. |

Each of these parts works in harmony. The headstock and tailstock align to hold the workpiece. The bed provides a solid base. The tool rest and banjo allow precise tool positioning. Together, they enable accurate and efficient woodturning.

The Bed: Foundation Of The Lathe

The bed of a wood-turning lathe machine serves as its foundation. It is the most crucial part of the lathe. The bed ensures the stability and accuracy of the machine. It supports all other parts, ensuring precise operations.

Types Of Lathe Beds

There are different types of lathe beds available. Each type has its unique characteristics and benefits. The most common types include:

- Flat Bed: Suitable for light-duty work. It is easy to manufacture and maintain.

- V-Bed: Offers better alignment and stability. Ideal for medium-duty operations.

- Dovetail Bed: Provides excellent precision. Best for heavy-duty tasks.

Materials And Design

The material of the lathe bed affects its durability and performance. Common materials include:

| Material | Properties |

|---|---|

| Cast Iron | High rigidity and vibration damping. |

| Steel | Strong and durable, but less vibration damping. |

The design of the lathe bed also plays a significant role. A well-designed bed ensures smooth and precise operations. Key design aspects include:

- Width: Wider beds offer more stability.

- Length: Longer beds allow for turning larger workpieces.

- Weight: Heavier beds reduce vibration and improve accuracy.

Credit: woodandshop.com

Headstock: Powering The Machine

The headstock is a crucial part of the wood turning lathe machine. It provides the necessary power to rotate the workpiece. This rotation allows for precise cutting and shaping of wood. Let’s explore its key features and maintenance tips.

Key Features

- Motor: The motor powers the headstock. It determines the machine’s speed and torque.

- Spindle: The spindle holds the workpiece. It rotates it with the help of the motor.

- Bearings: Bearings ensure smooth rotation. They reduce friction and wear.

- Pulley System: The pulley system controls the speed. It allows for different speed settings.

- Handwheel: The handwheel helps in manual adjustments. It provides better control over the rotation.

Maintenance Tips

- Regular Lubrication: Lubricate the bearings and spindle. Use high-quality grease.

- Check Belt Tension: Ensure the belts are tight. Loose belts can affect performance.

- Clean the Headstock: Remove dust and wood chips. Use a soft brush for cleaning.

- Inspect Motor: Check the motor for overheating. Ensure proper ventilation.

- Tighten Fasteners: Regularly tighten all bolts and screws. Loose parts can cause vibration.

By following these tips, you can keep your headstock in top condition. This ensures smooth and efficient operation of your wood turning lathe machine.

Tailstock: Support And Precision

The tailstock is a critical component of the wood turning lathe machine. It provides essential support and ensures precision during the turning process. This component holds the workpiece securely, allowing for accurate and stable turning.

Adjustment Mechanisms

The tailstock features various adjustment mechanisms to enhance its versatility. These mechanisms allow users to fine-tune the position and pressure of the tailstock. Proper adjustments ensure that the workpiece is centered and stable.

- Handwheel Adjustment: This mechanism allows for easy movement of the tailstock along the lathe bed.

- Locking Lever: This lever securely locks the tailstock in place.

- Quill Adjustment: The quill can be adjusted to move the center point closer or further.

Alignment With Headstock

The alignment of the tailstock with the headstock is crucial for achieving precision. Misalignment can cause inaccuracies and vibrations.

| Alignment Check | Procedure |

|---|---|

| Visual Inspection | Ensure the tailstock center aligns with the headstock center visually. |

| Test Cut | Perform a test cut to check for any misalignment. |

| Dial Indicator | Use a dial indicator to measure alignment precisely. |

Regular checks and adjustments ensure that the tailstock remains perfectly aligned with the headstock. This alignment is key for achieving accurate and precise woodturning results.

Tool Rest: Control And Comfort

The tool rest is an essential part of a wood turning lathe machine. It provides control and comfort while shaping wood. Ensuring a smooth operation, it supports the turner’s tools. This section will delve into its design variations and safety considerations.

Design Variations

Tool rests come in various designs, each serving a unique purpose. Common types include the straight tool rest, curved tool rest, and modular tool rest.

- Straight Tool Rest: Ideal for most general turning tasks.

- Curved Tool Rest: Best for turning bowls and curved shapes.

- Modular Tool Rest: Allows customization with different attachments.

Each design variation provides specific advantages. Choose based on the project requirements and personal preference.

Safety Considerations

Safety is critical when using a tool rest. Here are some key points to ensure safe operation:

- Proper Adjustment: Always adjust the tool rest to the correct height.

- Secure Tightening: Ensure the tool rest is securely tightened before starting.

- Regular Inspection: Check the tool rest for any damage or wear regularly.

Following these safety considerations can prevent accidents and ensure a smooth woodturning experience.

The Carriage: Movement And Control

The carriage is a crucial part of a wood turning lathe machine. It allows precise control and movement of the cutting tool. This ensures smooth and accurate woodwork. Understanding its components and functions can enhance your woodturning skills.

Components Of The Carriage

The carriage consists of several important parts. These parts work together for effective movement and control.

| Component | Function |

|---|---|

| Cross Slide | Moves the tool perpendicular to the workpiece. |

| Compound Rest | Holds the tool post and tool holder. |

| Tool Post | Secures the cutting tool in place. |

| Apron | Houses the handwheel and other controls. |

Handwheel Functions

The handwheel is a vital control element on the lathe. It allows manual movement of the carriage.

- Longitudinal Handwheel: Moves the carriage along the lathe bed.

- Cross Slide Handwheel: Controls the tool’s movement across the workpiece.

Using the handwheel ensures precision in your woodturning projects. Mastering the handwheel functions improves your accuracy and efficiency.

Spindle: The Rotational Core

The spindle is the heart of a wood turning lathe machine. It is responsible for the rotational motion that shapes the wood. Without a well-functioning spindle, precise woodwork is impossible. Understanding its parts and types is key for any woodworker.

Spindle Types

There are various types of spindles, each suited for different tasks. Here’s a table to help understand the different spindle types:

| Type | Description | Best For |

|---|---|---|

| Fixed Spindle | Does not move axially | Basic turning |

| Rotating Spindle | Moves both rotationally and axially | Complex designs |

| Live Spindle | Has a bearing system | High-speed turning |

Choosing The Right Spindle

Choosing the right spindle depends on the type of work you do. Here are some tips:

- For basic work, a fixed spindle is sufficient.

- For more complex designs, a rotating spindle is ideal.

- For high-speed turning, opt for a live spindle.

Remember, the spindle you choose directly affects your woodwork quality. Always consider your specific needs before making a decision.

Motor: Driving The Wood Lathe

The motor is the heart of a wood lathe. It powers the machine to shape and carve wood. A well-functioning motor ensures smooth operation and precision.

Power Specifications

The power of a wood lathe motor is measured in horsepower (HP). Most wood lathes have motors ranging from 1/2 HP to 2 HP. The higher the HP, the more powerful the lathe. Choose a motor with the right HP for your projects.

| Horsepower (HP) | Use Case |

|---|---|

| 1/2 HP | Small projects, like pens and ornaments |

| 1 HP | Medium projects, like bowls and vases |

| 2 HP | Large projects, like furniture legs |

Variable Speeds And Controls

Variable speed controls allow you to adjust the motor speed. This is crucial for different wood types and projects. Most modern wood lathes come with electronic variable speed controls. These controls offer smooth and precise speed adjustments.

Here are some benefits of variable speed controls:

- Better control over cutting and shaping

- Reduced chances of wood cracking

- Enhanced safety during operation

Look for a lathe with easy-to-use speed controls. Some lathes have digital displays for accurate speed settings. This feature is helpful for beginners and experts alike.

Credit: woodwhirled.com

Accessories And Attachments

Wood turning lathe machines are versatile tools. They need various accessories and attachments to perform different tasks. These additions enhance the machine’s functionality and precision. Let’s explore the most essential accessories and attachments for wood turning lathes.

Chucks And Faceplates

Chucks and faceplates are vital for securing the wood piece. Chucks hold the wood firmly, allowing intricate designs. They come in different types, such as four-jaw chucks and scroll chucks.

| Type | Purpose |

|---|---|

| Four-jaw chucks | Offer a strong grip on irregular shapes |

| Scroll chucks | Enable quick adjustments for repetitive tasks |

Faceplates are another essential tool. They attach flat pieces of wood to the lathe. Ideal for turning bowls and platters, they provide stability and precision.

Specialized Cutting Tools

Specialized cutting tools are crucial for detailed woodwork. These tools come in various shapes and sizes. They include gouges, skews, and parting tools.

- Gouges: Perfect for creating curves and hollows.

- Skews: Ideal for smooth finishes and fine details.

- Parting tools: Useful for cutting and separating pieces.

Each tool serves a unique purpose. Using the right tool ensures precision and quality. Proper maintenance of these tools is essential for long-lasting performance.

Safety Measures And Best Practices

Operating a wood turning lathe machine can be both rewarding and hazardous. Understanding and adhering to safety measures and best practices is crucial. This guide will help you stay safe and efficient while working with your lathe machine.

Protective Gear

Wearing the right protective gear can prevent injuries. Always wear safety goggles to protect your eyes from flying debris. Use ear protection to shield your ears from loud noises. Wear a dust mask to avoid inhaling wood particles.

Clothing is also important. Wear tight-fitting clothes to avoid getting caught in the machine. Use non-slip footwear to maintain good footing. Gloves can protect your hands but avoid loose-fitting ones.

Operating Procedures

Follow strict operating procedures to ensure safety. Before starting, ensure all parts are secure. Check the lathe machine for any loose or damaged parts.

Always start the lathe at a low speed. Gradually increase the speed once you are comfortable. Stand to the side when turning on the machine. This practice can protect you from flying debris.

| Procedure | Step |

|---|---|

| Starting the Machine |

|

| During Operation |

|

During operation, keep your hands away from moving parts. Use proper tools for each task. Maintain a clean workspace to avoid tripping hazards.

Monitor the machine constantly. Stop immediately if you notice anything unusual. Regular maintenance checks can prevent accidents.

Maintenance And Troubleshooting

Keeping your wood turning lathe machine in top condition is essential for smooth operation. Regular maintenance prevents issues and extends the machine’s life. This section focuses on regular upkeep and troubleshooting common problems with your lathe machine.

Regular Upkeep

Regular maintenance ensures the lathe machine runs smoothly. Here are some essential tasks:

- Clean the machine after each use to remove wood shavings and dust.

- Lubricate moving parts to prevent wear and tear.

- Check the belts for tension and wear.

- Inspect the tool rest for alignment and damage.

- Sharpen cutting tools regularly for optimal performance.

Common Issues And Solutions

Even with regular maintenance, problems may arise. Here are some common issues and their solutions:

| Issue | Solution |

|---|---|

| Machine vibration | Check for loose parts and ensure the lathe is level. |

| Uneven cuts | Sharpen tools and check tool rest alignment. |

| Motor overheating | Ensure proper ventilation and check for obstructions. |

| Belt slippage | Adjust belt tension and replace worn belts. |

Addressing these issues promptly will keep your lathe machine in top shape. Regular checks and maintenance are key to avoiding major problems.

Advancements In Wood Turning Technology

Wood turning has evolved with technology. Modern machines bring precision and ease. New advancements make wood turning more efficient and exciting.

Cnc Integration

CNC machines have revolutionized wood turning. They offer unmatched precision and repeatability. A CNC wood lathe uses computer programming to control the machine. This allows for intricate designs and patterns.

With CNC integration, woodworkers can create complex shapes. The machine reads digital files and follows exact instructions. This reduces errors and waste.

Here are some benefits of CNC integration:

- High precision

- Consistency in production

- Reduced material waste

- Ability to replicate intricate designs

Overall, CNC integration brings a new level of excellence to wood turning.

Innovations In Wood Turning

Innovations in wood turning tools and techniques are constant. New materials and designs make tools more effective. This makes wood turning easier and more enjoyable.

Ergonomic designs reduce strain on the user. High-speed steel and carbide-tipped tools offer longer life and better performance. These innovations help woodworkers achieve better results.

Here are some key innovations in wood turning:

| Innovation | Benefit |

|---|---|

| Ergonomic tool handles | Reduce user fatigue |

| High-speed steel tools | Longer tool life |

| Carbide-tipped tools | Sharper and more durable |

| Variable speed control | Better control over turning |

These innovations improve the wood turning experience. They make it more accessible to beginners and hobbyists.

Frequently Asked Questions

What Are The Parts Of A Wood Lathe Machine?

A wood lathe machine consists of the headstock, tailstock, bed, tool rest, and motor. The headstock holds the workpiece. The tailstock supports the other end. The bed provides stability. The tool rest guides cutting tools. The motor powers the machine.

What Are The 5 Major Parts Of The Lathe Machine?

The 5 major parts of a lathe machine are the bed, headstock, tailstock, carriage, and lead screw.

How Do I Identify Wood Lathe Tools?

Identify wood lathe tools by their shapes and functions. Common tools include gouges, skew chisels, parting tools, and scrapers. Check the handle and blade for labels.

What Are The Four Basic Tools You Need When Using The Wood Lathe?

The four basic tools for using a wood lathe are a roughing gouge, spindle gouge, parting tool, and skew chisel.

Conclusion

Understanding wood turning lathe machine parts is essential for any woodworking enthusiast. Proper knowledge enhances efficiency and precision. Invest time to familiarize yourself with each component. This will improve your craftsmanship and safety. Keep exploring and practicing, as mastery comes with experience.

Happy woodworking!