Table of Contents

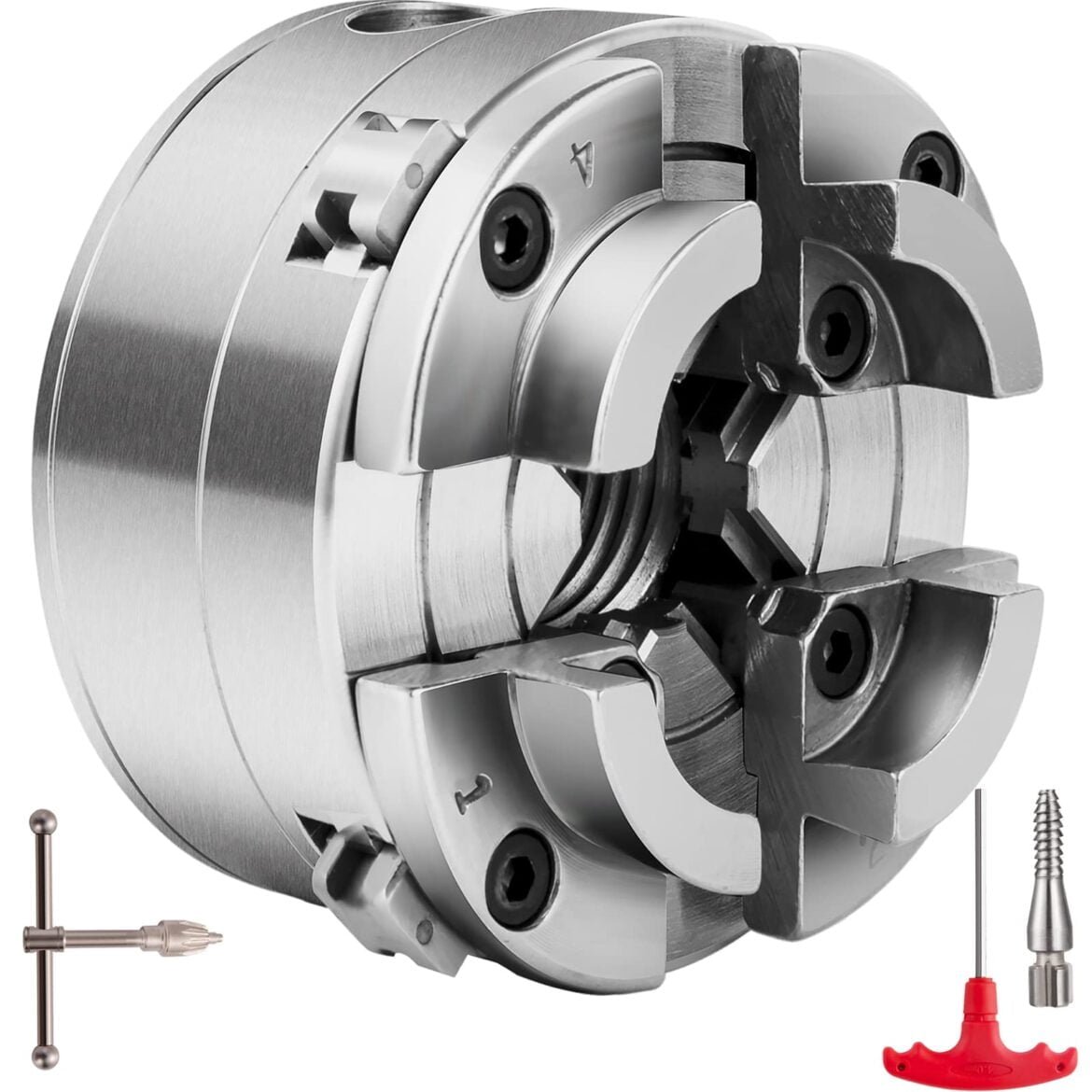

Wood turning lathe chucks are essential tools for woodworkers. They securely hold the workpiece in place during turning.

Wood turning lathe chucks play a crucial role in woodturning projects. These devices clamp onto the wood, providing stability and precision. With a reliable chuck, woodworkers can achieve intricate designs and smooth finishes. Chucks come in various sizes and types, each suited for different tasks.

From basic models to advanced versions, there’s a chuck for every skill level and project need. Investing in a quality lathe chuck enhances both efficiency and safety in the workshop. Whether you’re a hobbyist or a professional, the right chuck can make all the difference in your woodturning endeavors.

Credit: www.amazon.com

Introduction To Wood Turning Lathe Chucks

Wood turning lathe chucks are important tools. They hold wood in place on the lathe. This allows for safe and accurate turning. Chucks make it easier to shape wood. They come in different types and sizes. Each type has its own use. Knowing the right chuck can improve your woodturning projects. Always choose the right chuck for your task.

Chucks hold the wood tight. This helps in making precise cuts. They also reduce wobbling. Wobbling can ruin your work. Good chucks make turning smoother. This means better results. Chucks also allow for quick changes. You can switch pieces easily. This saves time and effort.

| Type | Description |

|---|---|

| Scroll Chuck | Holds wood with jaws. Great for round objects. |

| Collet Chuck | Grips smaller pieces tightly. Good for detailed work. |

| Faceplate | Secures large, flat pieces. Ideal for bowls. |

| Pin Chuck | Uses pins to hold wood. Best for small items. |

Key Features Of Quality Lathe Chucks

Lathe chucks come with different jaw types. Two-jaw chucks hold square or rectangular pieces. Three-jaw chucks are best for round objects. Four-jaw chucks provide flexibility. They can hold odd-shaped pieces securely. Scroll chucks have a synchronized movement. Independent chucks let you adjust each jaw separately. Each type serves a unique purpose in wood turning.

Quality lathe chucks are made from hardened steel. This material ensures durability. High-grade steel resists wear and tear. Precision engineering is crucial. It ensures accurate grip and alignment. Corrosion-resistant coatings add to longevity. Good chucks also have smooth operating mechanisms. These features make them reliable and efficient.

Choosing The Right Chuck For Your Project

Understand the needs of your woodturning project. Different projects need different types of chucks. Small projects might need a simple chuck. Large projects might need a stronger chuck. Think about the size and shape of the wood you will turn. Select a chuck that fits those needs.

Not all chucks fit all lathes. Check the spindle size of your lathe. Make sure the chuck matches that size. Some chucks are made for specific brands of lathes. Read the manufacturer’s guide to ensure compatibility. Using the right chuck helps in safe and effective woodturning.

Installation And Maintenance

Installing wood turning lathe chucks requires precise alignment for optimal performance. Regular maintenance ensures longevity, preventing wear and tear.

Setting Up Your Chuck Properly

Make sure your lathe is switched off. Attach the chuck to the spindle carefully. Tighten it securely using the provided key. Align the jaws with your workpiece. Balance the workpiece before starting. Check for any loose parts.

Routine Maintenance Tips

Clean the chuck after each use. Remove any sawdust and debris. Lubricate the moving parts regularly. Inspect for wear and tear. Replace damaged parts immediately. Store in a dry place to prevent rust. Check alignment before each use.

Safety Tips For Using Lathe Chucks

Always wear safety goggles to protect your eyes. Use ear protection to guard against loud noises. Gloves can keep your hands safe from splinters. A dust mask helps to avoid breathing in wood dust. Wear tight clothing to prevent getting caught in the lathe. Make sure your hair is tied back if it is long.

Always check the chuck for tightness before starting. Keep your hands away from the spinning chuck. Stop the lathe before making any adjustments. Use the correct speed for the material you are working on. Inspect the wood for cracks or defects before turning. Clean the workspace to avoid tripping hazards.

Advanced Techniques And Tips

Use a four-jaw chuck to hold wood tightly. This helps in getting a firm grip. Adjust the jaws evenly to improve accuracy. Always check the alignment before starting. Use soft jaws for delicate wood pieces. This prevents damage. A tailstock can provide additional support. This reduces wobbling.

For better results, use sharp tools. They make cleaner cuts. Also, keep the work area clean. This avoids slipping. Practice regularly to improve skills. Make sure to wear safety gear. This protects you from accidents.

Chucks can help in making unique bowls. Use a compression chuck to hold the bowl firmly. You can also create detailed spindle work. This includes making chair legs and handles. Use a pin chuck for small, intricate designs.

Hollow forms can also be made using chucks. This involves hollowing out a piece of wood. Use a scroll chuck for this purpose. Chucks are versatile tools. They help in various woodturning projects. Experiment with different techniques. This will improve creativity and skills.

Common Challenges And Solutions

Slippage can cause frustration. Ensure the chuck is properly tightened. Inspect the jaws for any wear or damage. Clean the chuck regularly to remove debris. Use high-quality wood to reduce the chances of slippage. Check the alignment of the wood piece before starting. Consider using a tailstock for additional support. Avoid using excessive force while turning.

Difficult woods can be challenging. Choose the right lathe speed for the wood type. Sharp tools are essential for hard woods. Take light cuts to avoid stressing the wood. Use a steady hand to prevent accidents. Stabilize the wood if it is prone to cracking. Sand the wood surface to make it smooth.

Credit: www.axminstertools.com

Future Trends And Innovations

New materials are making chucks stronger. These materials also make them lighter. 3D printing helps create unique chuck designs. These designs fit better for different wood pieces. Smart chucks can adjust themselves. They use sensors to grip wood securely. This makes wood turning safer.

Eco-friendly chucks are becoming popular. They use materials that are better for the planet. Recycled metals and plastics are used. This helps reduce waste. Energy-efficient machines also save power. They use less electricity, making wood turning greener. Sustainable practices are good for the environment. They help keep our planet healthy.

Credit: www.axminstertools.com

Frequently Asked Questions

What Chuck Do I Need For My Wood Lathe?

Choose a chuck that fits your lathe’s spindle size and thread. Consider a four-jaw chuck for versatility.

What Is The Most Commonly Used Lathe Chuck?

The most commonly used lathe chuck is the three-jaw chuck. It is versatile and self-centering, ideal for round and hexagonal workpieces.

What Size Chuck For Lathe?

Lathe chucks typically range from 3 to 12 inches. Choose the size based on your lathe’s spindle and project needs.

How Do You Use A 4 Jaw Chuck On A Wood Lathe?

To use a 4 jaw chuck on a wood lathe, first center your workpiece. Adjust each jaw individually for secure grip. Ensure the piece is balanced and tightly held. Rotate manually to check alignment. Begin turning at a low speed, increasing gradually as needed.

Always follow safety precautions.

Conclusion

Choosing the right wood turning lathe chuck enhances your woodworking projects. It ensures precision, safety, and efficiency. Explore different types to find the perfect fit for your needs. Invest in quality chucks for better results and a smoother woodworking experience.

Happy turning!