Table of Contents

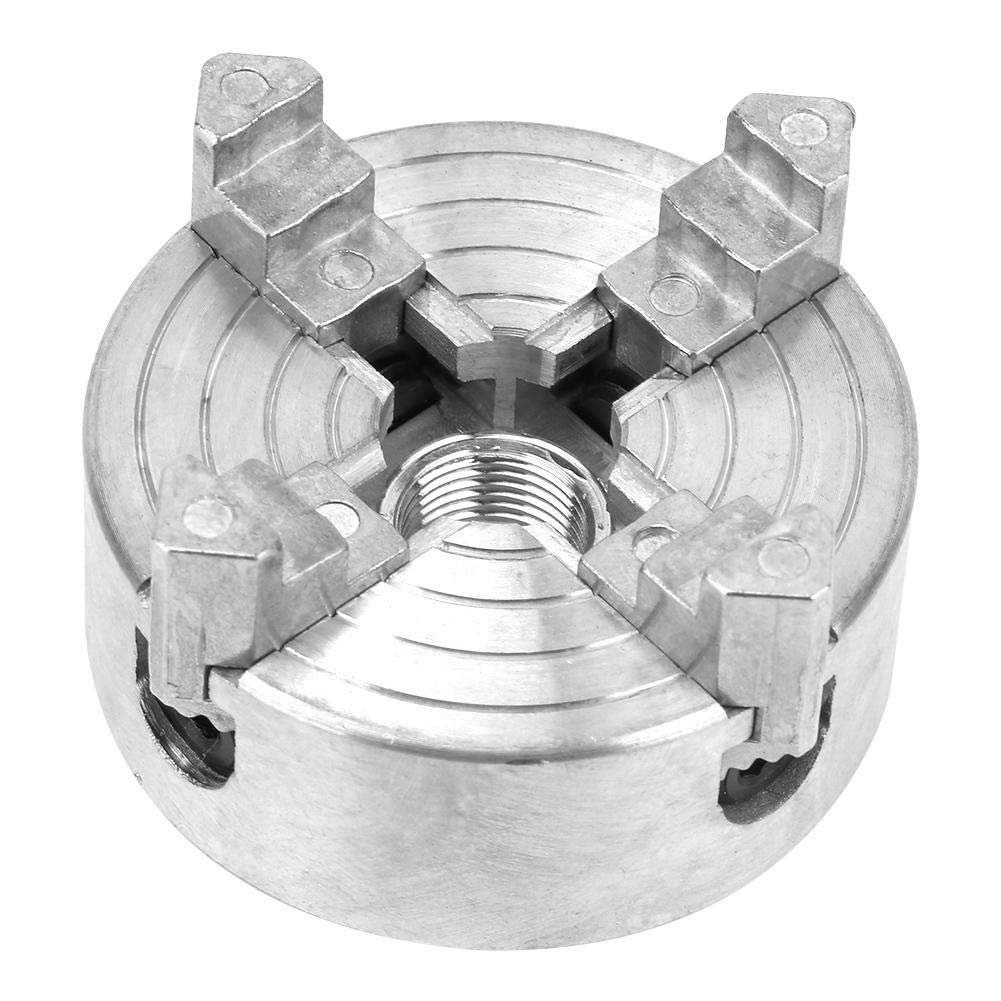

A wood turning lathe chuck holds and secures wood pieces on a lathe. It ensures precision and stability during turning.

A wood turning lathe chuck is essential for any woodworking enthusiast. It clamps the wood securely, allowing for intricate and precise turning. This tool enhances safety and accuracy, making it indispensable in both hobbyist and professional workshops. Different types of chucks, such as four-jaw and scroll chucks, cater to various turning needs.

Investing in a quality lathe chuck can significantly improve your woodworking projects. Whether creating bowls, spindles, or intricate designs, a reliable chuck ensures your workpiece stays firmly in place. Always choose a chuck that fits your lathe and meets your specific project requirements for the best results.

Introduction To Wood Turning Lathe Chucks

Wood turning lathe chucks are essential tools in woodworking. They help secure wood pieces for precise turning. With the right chuck, your woodworking projects become easier and more accurate.

The Role Of Chucks In Wood Turning

Chucks play a vital role in wood turning. They hold the wood securely on the lathe. This allows you to shape the wood accurately.

Without a proper chuck, the wood may slip or wobble. This can lead to mistakes and uneven shapes.

Using a chuck ensures safety and precision. It makes wood turning more enjoyable and efficient.

Types Of Lathe Chucks

| Type of Chuck | Features | Best For |

|---|---|---|

| Four-Jaw Chuck | Adjustable jaws, versatile | Various shapes and sizes |

| Scroll Chuck | Easy to use, quick adjustments | Round objects |

| Collet Chuck | High precision, holds small items | Detailed work |

Each type of lathe chuck has unique benefits. Choose the right one for your specific needs.

- Four-Jaw Chuck: Ideal for complex shapes.

- Scroll Chuck: Great for round pieces.

- Collet Chuck: Perfect for detailed work.

Understanding the different chucks can improve your woodworking skills. It helps you choose the best tool for each project.

Credit: www.amazon.com

Selecting The Right Chuck For Your Project

Choosing the right chuck for your wood turning project is crucial. The right chuck ensures precision and safety. Let’s dive into the factors to consider and compare different models.

Factors To Consider

Several factors play a role in selecting a wood turning lathe chuck:

- Project Type: Consider the type of project you’re working on.

- Chuck Size: Choose a chuck size that fits your lathe and project needs.

- Grip Strength: Ensure the chuck has a strong grip to hold the wood securely.

- Material: Check if the chuck material is durable and high-quality.

- Ease of Use: Opt for a chuck that is easy to install and use.

Comparing Chuck Models

Different chuck models offer various features. Here are some popular options:

| Model | Size | Grip Strength | Material | Ease of Use |

|---|---|---|---|---|

| Nova G3 | Small to Medium | High | Steel | Easy |

| Oneway Stronghold | Large | Very High | Steel | Moderate |

| Barracuda CSC3000C | Medium | High | Aluminum | Easy |

Choosing the right chuck depends on your specific needs. Consider these factors and compare models to make an informed decision.

Setting Up Your Chuck: A Step-by-step Guide

Setting up your wood turning lathe chuck is essential. A proper setup ensures safety and precision. Follow this guide to get your chuck ready in no time.

Preparing Your Lathe

Begin by ensuring your lathe is clean. Remove any debris or dust. A clean lathe ensures a smooth installation.

Check the alignment of your lathe. Misalignment can cause inaccurate cuts. Use a dial indicator to verify precision.

Next, gather your tools. You will need a wrench, a chuck key, and protective gloves. Having tools ready speeds up the process.

Installing The Chuck

First, turn off and unplug the lathe. Safety is the top priority.

Remove the old chuck or faceplate. Use your wrench to loosen it. Carefully take it off to avoid damaging threads.

Clean the spindle threads. Use a brush to remove any debris. Clean threads ensure a secure fit for the new chuck.

Now, screw the new chuck onto the spindle. Turn it by hand until it is snug. Avoid cross-threading to prevent damage.

Tighten the chuck using the chuck key. Make sure it is secure but not overly tight. Over-tightening can damage the chuck or spindle.

Finally, test the chuck. Turn on the lathe at a low speed. Check for any wobbling or misalignment. If everything is smooth, your chuck is ready for use.

| Step | Action |

|---|---|

| 1 | Turn off and unplug the lathe |

| 2 | Remove old chuck or faceplate |

| 3 | Clean spindle threads |

| 4 | Screw new chuck onto spindle |

| 5 | Tighten chuck with chuck key |

| 6 | Test for wobbling or misalignment |

Follow these steps to ensure your wood turning lathe chuck is set up correctly. A proper setup leads to better results and a safer work environment.

Basic Techniques For Using A Lathe Chuck

Using a lathe chuck can be a rewarding experience. Knowing the basic techniques ensures precision and safety. Below are essential tips for mastering the art of using a lathe chuck.

Adjusting Jaw Tension

Proper jaw tension is crucial for secure work. Adjust the tension by turning the chuck key. Ensure the jaws grip the workpiece firmly. Over-tightening can damage the workpiece. Under-tightening may lead to slippage. Always check the manufacturer’s guidelines for the correct tension.

Centering Your Workpiece

Centering the workpiece ensures balanced rotation. Align the workpiece with the lathe’s axis. Use a dial indicator for precision. Tighten the chuck’s jaws gradually. Rotate the workpiece by hand to check alignment. Adjust as needed until perfectly centered.

Advanced Chuck Techniques For Experienced Turners

Experienced wood turners can push their skills further with advanced chuck techniques. These methods allow for creating intricate shapes and working with unusual materials. Mastering these techniques can elevate your woodturning projects to new heights.

Creating Intricate Shapes

Creating intricate shapes requires precision and skill. Using a wood turning lathe chuck, you can achieve delicate and complex designs. Follow these steps for best results:

- Plan your design: Sketch your shape before starting.

- Secure the wood: Ensure the wood is firmly in the chuck.

- Use fine tools: Fine chisels help in detailing.

- Work slowly: Take your time to avoid mistakes.

These steps help in achieving detailed and precise shapes. Practicing these techniques will enhance your skills further.

Working With Unusual Materials

Working with unusual materials can be challenging but rewarding. Materials like acrylic, metal, or exotic woods require special attention. Here are some tips:

| Material | Tip |

|---|---|

| Acrylic | Use a slow speed to avoid melting. |

| Metal | Ensure your tools are sharp and strong. |

| Exotic Woods | Check for any hidden defects or cracks. |

Understanding these materials and their properties is crucial. This helps in achieving the desired outcome without damaging the material.

Credit: www.axminstertools.com

Maintenance And Care For Longevity

Wood turning lathe chucks are valuable tools for woodworkers. Proper maintenance and care ensure they last long and perform well. This section covers essential practices for keeping your lathe chuck in top condition.

Regular Cleaning Practices

Keeping your lathe chuck clean is crucial. Dust and wood shavings can cause wear and tear.

- Wipe the chuck with a soft cloth after each use.

- Use a brush to remove debris from hard-to-reach areas.

- Lubricate moving parts with machine oil regularly.

- Check for rust and use a rust remover if needed.

Regular cleaning prevents build-up that could affect performance.

Troubleshooting Common Issues

Even with proper care, issues can arise. Here are some common problems and their solutions:

| Problem | Solution |

|---|---|

| Chuck not holding workpiece | Tighten the jaws and check for wear. |

| Excessive vibration | Ensure the chuck is balanced and properly mounted. |

| Difficulty in opening/closing jaws | Clean and lubricate the jaws. |

Addressing issues early can prevent major repairs and extend the life of your lathe chuck.

Safety Tips For Working With A Lathe Chuck

Working with a wood turning lathe chuck can be rewarding. Safety should be your top priority. Follow these tips to ensure a safe working environment.

Protective Gear

Always wear protective gear. This includes safety glasses and a face shield. Safety glasses protect your eyes from flying debris. A face shield provides extra protection.

Wear hearing protection to protect your ears from loud noises. Use non-slip shoes to avoid slipping. Consider wearing gloves for added hand protection.

Avoiding Accidents

Ensure the lathe is turned off before making adjustments. Check that the workpiece is securely fastened in the chuck. Loose workpieces can cause accidents.

Keep your hands and fingers away from the spinning chuck. Use tools to adjust the wood, not your hands. Maintain a clean and organized workspace to prevent tripping hazards.

| Safety Tips | Details |

|---|---|

| Wear Protective Gear | Safety glasses, face shield, hearing protection, non-slip shoes, gloves |

| Secure Workpiece | Ensure the workpiece is tightly fastened |

| Hands and Fingers | Keep them away from the spinning chuck |

| Clean Workspace | Maintain a clutter-free environment |

Inspiring Projects To Try With Your Lathe Chuck

Using a wood turning lathe chuck opens up a world of creative possibilities. Whether you are just starting or have years of experience, there are always new projects to explore.

Beginner-friendly Ideas

Starting with simple projects helps you master basic techniques.

- Wooden Pens: Crafting wooden pens is a great beginner project. They are small and manageable.

- Candle Holders: Easy to make and perfect for gifts. You can use different wood types.

- Bowls: Turning small bowls teaches you the basics of shaping wood.

Challenges For Advanced Turners

Experienced turners can tackle more intricate and ambitious projects.

- Hollow Forms: Creating hollow forms requires precision and patience. They are stunning pieces of art.

- Segmented Turning: Combine different wood pieces to create unique patterns. It is a complex but rewarding technique.

- Intricate Boxes: Turn small boxes with detailed lids. They are perfect for storing treasures.

Project Ideas Table

| Project | Skill Level | Description |

|---|---|---|

| Wooden Pens | Beginner | Small, easy-to-handle projects. |

| Candle Holders | Beginner | Simple shapes, great for gifts. |

| Bowls | Beginner | Learn basic shaping techniques. |

| Hollow Forms | Advanced | Requires precision and patience. |

| Segmented Turning | Advanced | Combine different wood pieces. |

| Intricate Boxes | Advanced | Turn boxes with detailed lids. |

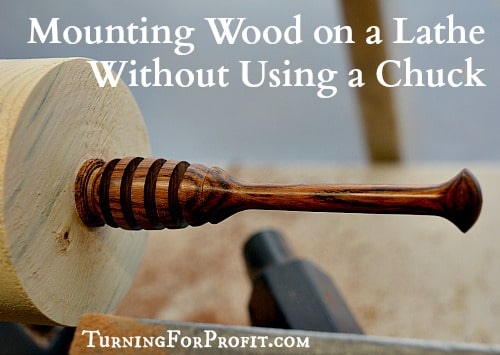

Credit: www.turningforprofit.com

Frequently Asked Questions

What Chuck Do I Need For My Wood Lathe?

Choose a chuck compatible with your wood lathe’s spindle size and thread. Popular options include four-jaw chucks for versatility.

What Is The Difference Between A Faceplate And A Chuck On A Wood Lathe?

A faceplate secures flat wood pieces on a lathe, while a chuck holds round or irregularly shaped objects for turning.

How Do You Use A 4-jaw Chuck On A Wood Lathe?

To use a 4-jaw chuck on a wood lathe, mount the chuck securely. Insert the wood, then tighten each jaw evenly. Adjust the wood until centered. Start the lathe at a low speed.

What Is A Vacuum Chuck For A Wood Lathe?

A vacuum chuck for a wood lathe holds workpieces securely using suction. It simplifies turning and ensures precision.

Conclusion

Choosing the right wood turning lathe chuck can enhance your woodworking projects. It’s essential for precision and efficiency. With the right chuck, your craftsmanship reaches new heights. Invest in quality and see the difference it makes. Your woodworking journey will become more enjoyable and rewarding.