Table of Contents

Wood lathe turning speeds vary based on the diameter and type of wood. Proper speed ensures safety and quality in woodworking.

Wood lathe turning is a precise craft that requires careful attention to detail. The correct speed for turning wood on a lathe depends on the wood’s diameter and type. Small diameters generally need higher speeds, while larger diameters require slower speeds to ensure safety and accuracy.

Understanding the optimal turning speed can prevent accidents and improve the quality of the final product. Many woodworkers refer to a wood lathe turning speeds chart to determine the best speeds for their specific projects. By adhering to recommended speeds, you can achieve smoother finishes and reduce wear on your tools.

The Art Of Woodturning

Woodturning is a beautiful and ancient craft. It transforms raw wood into stunning shapes. This craft requires skill, patience, and the right tools. One key aspect is the wood lathe turning speeds chart. This chart helps woodturners choose the correct speed for their projects. Let’s explore the essence and history of woodturning.

Essence Of Speed In Woodturning

Speed is crucial in woodturning. It affects the quality and safety of your work. The right speed makes cutting smoother and safer. A slower speed is better for larger pieces. Faster speeds suit smaller, detailed work. Here is a simple table to guide you:

| Wood Diameter (inches) | Recommended RPM |

|---|---|

| 1-2 | 3000-4000 |

| 2-4 | 2500-3000 |

| 4-6 | 1500-2500 |

| 6-8 | 1000-1500 |

| 8-10 | 600-1000 |

Historical Evolution Of Wood Lathes

Wood lathes have a rich history. Ancient Egyptians used simple lathes around 1300 BC. They turned wood using a bowstring method. The Romans improved this with a pedal-powered lathe. In the Middle Ages, the lathe saw more advancements. Craftsmen used a spring pole lathe for better control.

During the Industrial Revolution, lathes became more advanced. Metal lathes allowed for more precision and power. Today, modern wood lathes are electrically powered. They offer variable speeds and greater accuracy. These advancements make woodturning easier and more enjoyable.

Understanding the history of wood lathes helps appreciate the craft. Each innovation made woodturning more efficient and creative. Now, woodturners can create intricate designs with ease.

Wood Lathe Basics

A wood lathe is an essential tool for woodworkers. It spins wood to shape it using various tools. Knowing the basics helps you get the best results.

Key Components Of A Wood Lathe

A wood lathe has several key components. Each part plays a vital role.

- Headstock: This holds the motor and spindle.

- Tailstock: Provides support for the workpiece.

- Tool Rest: Supports tools during cutting.

- Bed: The base where other parts are mounted.

Functionality And Design

The design of a wood lathe affects its functionality. Understanding the design helps in achieving precise results.

Speed Control: Adjusting speed is crucial for different tasks. Use the right speed for smooth finishes.

Stability: A stable lathe ensures accuracy. Check for vibrations during use.

Ease of Use: Simple designs make it easier to learn and operate.

| Component | Function |

|---|---|

| Headstock | Holds the motor and spindle. |

| Tailstock | Supports the workpiece. |

| Tool Rest | Supports tools during cutting. |

| Bed | Base for mounting parts. |

Determining The Right Speed

Choosing the right speed is crucial for wood lathe turning. It ensures safety and enhances the quality of your work. Understanding the factors that influence lathe speed can help you make better decisions.

Factors Influencing Lathe Speed

Several factors affect the speed of your wood lathe. These include:

- Wood Hardness: Harder woods need slower speeds.

- Tool Type: Different tools work better at various speeds.

- Diameter of the Wood: Larger diameters require slower speeds.

- Desired Finish: A finer finish often needs slower speeds.

Wood Hardness And Lathe Speed

Wood hardness plays a vital role in determining lathe speed. Here’s a simple chart to guide you:

| Wood Type | Speed (RPM) |

|---|---|

| Soft Woods (Pine, Cedar) | 1500-2000 |

| Medium Hardness (Walnut, Cherry) | 1200-1500 |

| Hard Woods (Oak, Maple) | 800-1200 |

Using the right speed for the wood type ensures a smooth finish. It also helps in preventing tool wear and tear.

Credit: turnawoodbowl.com

Speed Chart Essentials

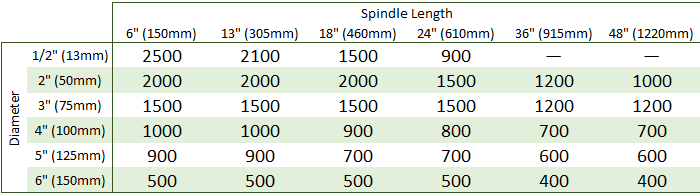

Understanding a wood lathe speed chart is crucial. It helps you achieve the best results. This guide covers the essentials. Knowing the correct speed enhances your work quality.

Reading A Wood Lathe Speed Chart

A wood lathe speed chart provides vital information. It shows the recommended speeds for various wood types and sizes. The chart typically includes:

- Wood Type

- Piece Diameter

- Recommended Speed

Below is a sample speed chart for better understanding:

| Wood Type | Piece Diameter (in inches) | Recommended Speed (RPM) |

|---|---|---|

| Softwood | 1 – 3 | 1500 – 2000 |

| Softwood | 4 – 6 | 1200 – 1500 |

| Hardwood | 1 – 3 | 1200 – 1500 |

| Hardwood | 4 – 6 | 1000 – 1200 |

Softwood needs higher speed compared to hardwood. Always check the chart before starting.

Practical Applications

Using the speed chart ensures safety. It also improves the finish of your work. Here are some practical applications:

- Bowl Turning: For a 4-inch hardwood bowl, set the speed at 1000 RPM.

- Spindle Turning: For a 2-inch softwood spindle, set the speed at 1500 RPM.

- Pen Turning: For small pen blanks, use speeds around 2000 RPM.

Adjust the speed according to the chart. This will help you achieve the best results. Always prioritize safety and quality in your work.

Safety First

Wood lathe turning is a rewarding activity. But safety must always come first. Understanding the correct turning speeds is crucial. Incorrect speeds can cause accidents and injuries.

Protective Gear And Precautions

Always wear the right protective gear. Safety goggles protect your eyes from flying debris. Wear a dust mask to avoid inhaling wood particles.

- Safety Goggles: Protects your eyes.

- Dust Mask: Prevents inhalation of dust.

- Hearing Protection: Shields your ears from noise.

- Gloves: Protect your hands from splinters.

Ensure your workspace is clean and organized. Clutter can lead to accidents. Keep your tools sharp and in good condition.

Recognizing Unsafe Speeds

Knowing the correct turning speeds is vital. Too high or too low speeds are dangerous.

| Wood Type | Diameter (inches) | Safe Speed (RPM) |

|---|---|---|

| Softwood | 0-2 | 1500-2000 |

| Softwood | 2-4 | 1000-1500 |

| Hardwood | 0-2 | 1200-1800 |

| Hardwood | 2-4 | 800-1200 |

- Start at a lower speed.

- Gradually increase as needed.

- Watch for any vibrations.

- Adjust speed if there are any issues.

Always follow the manufacturer’s guidelines. They provide the best speed recommendations. Check your lathe’s manual for more information.

Credit: gallowaywoodturners.co.uk

Fine-tuning Techniques

Discovering the right wood lathe turning speeds chart can be challenging. Fine-tuning techniques help achieve the perfect finish. Precision is key for smooth and efficient work.

Adjusting Speeds For Precision

Adjusting speeds can impact the quality of your work. Use the right speed for the wood type. Softwoods need different speeds than hardwoods.

Here is a quick reference table to help you:

| Wood Type | Diameter (inches) | Recommended Speed (RPM) |

|---|---|---|

| Softwood | 1-4 | 1500 – 3000 |

| Softwood | 4-8 | 1000 – 1500 |

| Hardwood | 1-4 | 1200 – 1800 |

| Hardwood | 4-8 | 600 – 1200 |

Troubleshooting Common Issues

Even with a chart, problems can arise. Understanding common issues helps resolve them quickly.

- Vibration: This can distort your work. Reduce speed or secure the piece better.

- Burn Marks: High speeds can cause this. Lower the speed or use sharper tools.

- Rough Finish: This means the speed is too low. Increase the speed slightly.

Fine-tuning your lathe speeds ensures better results. Always prioritize safety and precision.

Advanced Woodturning Projects

Advanced woodturning projects demand precise skills and knowledge. The right wood lathe turning speeds chart is crucial for these projects. By mastering variable speeds, you can create intricate designs and complex shapes. This section focuses on these advanced techniques.

Incorporating Variable Speeds

Using variable speeds allows for greater control and precision. Different woods require different speeds. A wood lathe turning speeds chart helps you choose the correct speed.

For softwoods, use higher speeds. For hardwoods, use lower speeds. This ensures a smooth finish and prevents wood damage. Below is a simple table showing suggested speeds:

| Wood Type | Speed (RPM) |

|---|---|

| Softwood | 2000 – 3000 |

| Hardwood | 1000 – 2000 |

| Dense Wood | 500 – 1000 |

Adjust speeds based on wood density. Always start slow and increase speed gradually. This prevents accidents and ensures quality work.

Creating Complex Shapes

Complex shapes require advanced techniques and tools. Use a combination of chisels and gouges. The correct speed is vital for these shapes.

Follow these steps to create complex shapes:

- Choose the correct wood type.

- Set the lathe to the recommended speed.

- Use sharp tools for precision.

- Start with rough shaping at lower speeds.

- Increase speed for detailed work.

Using a wood lathe turning speeds chart helps in every step. Remember to maintain tool sharpness. This ensures a clean cut and better finish.

Advanced woodturning projects are challenging but rewarding. With the right techniques and speeds, you can create stunning pieces.

Maintaining Your Wood Lathe

Maintaining your wood lathe is crucial for ensuring its longevity. Regular care and timely upgrades can keep your machine running smoothly. Below, we discuss essential maintenance tips and when to upgrade or replace parts.

Regular Care For Optimal Performance

Regular care is essential to keep your wood lathe in top shape. Follow these steps:

- Clean the lathe after every use. Remove wood shavings and dust.

- Lubricate moving parts with appropriate oils. This helps reduce friction.

- Check for loose bolts. Tighten them to avoid machine wobble.

- Inspect belts for wear and replace if necessary.

Creating a maintenance schedule can help. Stick to it for optimal performance.

When To Upgrade Or Replace Parts

Knowing when to upgrade or replace parts is important. Follow these guidelines:

- Motor issues: If the motor is noisy or weak, consider replacing it.

- Tool rest wear: Replace the tool rest if it shows significant wear.

- Tailstock problems: Upgrade the tailstock if it doesn’t hold workpieces securely.

- Bed wear: Replace the bed if it has deep grooves or uneven spots.

Upgrading parts can improve machine efficiency and accuracy.

Expanding Your Skillset

Mastering wood lathe turning speeds is crucial. It helps you achieve smooth and precise cuts. Expanding your skillset can open new doors. You will become more confident and proficient. Let’s explore some ways to grow your expertise.

Workshops And Community

Joining workshops can boost your skills. They offer hands-on experience and expert guidance. You can learn from experienced woodturners. These workshops often cover various techniques. Here’s what you can expect:

- Live demonstrations

- Personalized feedback

- Networking opportunities

Engaging with the woodturning community is also beneficial. You can share experiences and tips. Online forums and local clubs are great places to start.

Learning Resources And Guides

A wealth of learning resources is available. Books, online courses, and videos can help you. These guides can teach you about wood lathe turning speeds. Here are some recommended resources:

- Books: “The Lathe Book” by Ernie Conover

- Online Courses: Woodturning on Udemy

- Videos: YouTube channels like “Carl Jacobson”

These resources provide step-by-step instructions. They can help you understand and apply the correct speeds. Regular practice along with these guides will enhance your skills.

Credit: www.wwgoa.com

Frequently Asked Questions

How Fast Should A Wood Lathe Turn?

The speed of a wood lathe depends on the wood type and project size. For small projects, use 1500-2000 RPM. For larger projects, use 500-1000 RPM. Always adjust speed according to the specific task and material.

What Speed Should I Cut Wood Turning?

Cut wood turning at 1,000 to 3,000 RPM for best results. Adjust speed based on wood size and type.

What Is The Rule Of Thumb For The Speed Of A Wood Lathe?

The rule of thumb for wood lathe speed is 1,000 RPM for turning smaller pieces. For larger pieces, adjust speed down to 500 RPM or lower. Always ensure safety and proper tool use.

What Is The Speed Range Of A Lathe?

A lathe typically operates at speeds ranging from 50 to 3,000 RPM. Speed varies based on material and task.

Conclusion

Mastering the appropriate wood lathe turning speeds ensures smooth and precise projects. This chart simplifies speed selection for various materials. Use it to enhance your woodworking skills and achieve professional results. Keep practicing and refining your technique for the best outcomes.

Happy turning!