Table of Contents

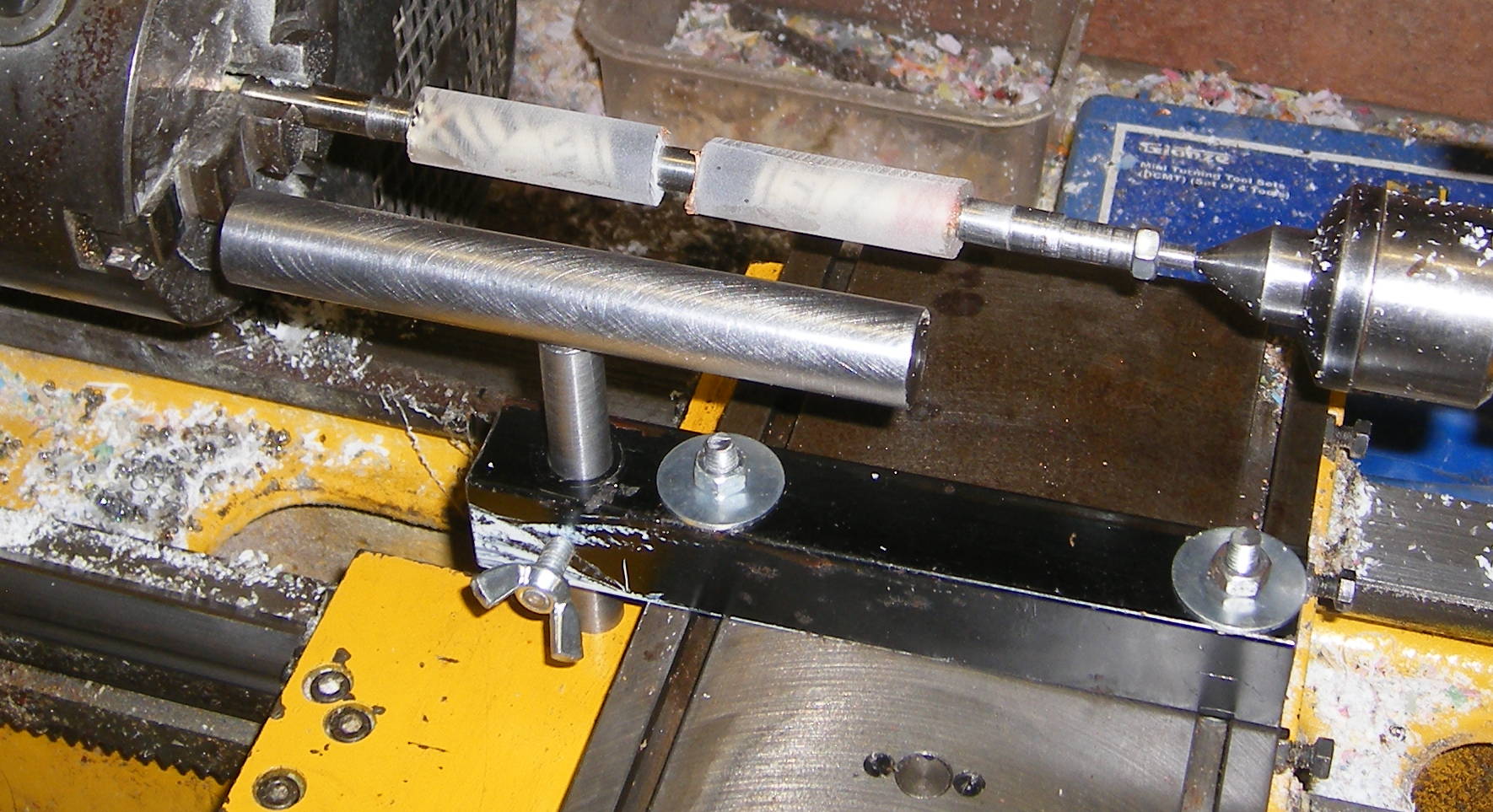

Turning wood on a metal lathe is possible but requires careful preparation and the right tools. The metal lathe must be cleaned thoroughly to avoid contamination.

Turning wood on a metal lathe can be a rewarding experience for hobbyists and professionals alike. Although metal lathes are primarily designed for metalworking, they can be adapted for woodturning with some adjustments. Use sharp, carbide-tipped tools to handle the wood effectively.

Secure the wood properly to prevent any accidents. Ensure the workspace is clean to avoid mixing metal shavings with wood dust. This cross-contamination can damage your tools and affect the quality of your work. Always wear protective gear to safeguard against wood chips and dust. Start with simple projects to get a feel for the process before moving on to more complex pieces.

Credit: www.penturners.org

The Fusion Of Wood And Metalworking

The fusion of wood and metalworking opens new possibilities for craftsmen. Using a metal lathe to turn wood can produce unique results. This combination enhances both precision and creativity.

Comparing Wood Lathes And Metal Lathes

Wood lathes and metal lathes have distinct features. Here’s a quick comparison:

| Feature | Wood Lathe | Metal Lathe |

|---|---|---|

| Material | Designed for wood | Handles both metal and wood |

| Precision | Less precise | Highly precise |

| Speed Control | Basic speed control | Advanced speed control |

| Rigidity | Less rigid | Very rigid |

| Tooling | Limited tooling options | Wide range of tooling |

Advantages Of Using A Metal Lathe For Wood

- Precision: Metal lathes offer higher precision for detailed work.

- Versatility: They can handle various materials, not just wood.

- Speed Control: Advanced speed control allows for smooth finishes.

- Durability: Metal lathes are more durable and robust.

- Tooling Options: A wide range of tooling can be used.

Using a metal lathe for woodturning can elevate your craftsmanship. The precision and versatility are unmatched.

Essential Tools For Wood Turning On A Metal Lathe

Woodturning on a metal lathe is a rewarding hobby. It offers precision and creativity. Having the right tools makes the job easier and more enjoyable. Let’s explore the essential tools needed for woodturning on a metal lathe.

Selecting The Right Chisels And Gouges

Choosing the right chisels and gouges is crucial. These tools shape the wood as it spins on the lathe. Here are the types of chisels and gouges you need:

- Roughing Gouge: Used for rough shaping and removing excess wood.

- Spindle Gouge: Ideal for detailed work and creating curves.

- Skew Chisel: Perfect for smooth finishing cuts.

- Parting Tool: Used for cutting deep grooves and separating pieces.

Each tool has a specific purpose. Using the right one ensures a smooth and precise turn.

Safety Gear For Metal Lathe Woodturning

Safety is paramount when woodturning on a metal lathe. Proper gear protects you from potential hazards. Here’s a list of essential safety gear:

- Safety Glasses: Protects your eyes from wood chips and dust.

- Face Shield: Provides full-face protection from flying debris.

- Dust Mask: Prevents inhalation of fine wood particles.

- Ear Protection: Shields your ears from loud noises.

- Gloves: Protects your hands from sharp tools and splinters.

Wearing the right safety gear reduces the risk of injury. Always prioritize safety in your woodturning projects.

Setting Up Your Metal Lathe For Wood

Woodturning on a metal lathe can be fun. It requires some setup. Here are steps to set up your metal lathe for wood.

Modifications And Accessories

To turn wood on a metal lathe, some modifications are needed. Woodturning tools and accessories are essential. Here are some important modifications:

- Tool rest: Use a tool rest designed for woodturning.

- Cutting tools: Use sharp carbide-tipped or HSS tools.

- Dust collection: Attach a dust collection system.

- Speed control: Ensure the lathe has variable speed control.

These modifications will help in turning wood safely and efficiently.

Securing Wood Blanks Properly

Properly securing wood blanks is crucial. Here are steps to do it:

- Centering: Ensure the wood blank is centered.

- Chucks: Use woodturning chucks or faceplates.

- Tailstock: Use the tailstock to support longer pieces.

- Clamping: Ensure the wood is securely clamped.

Following these steps ensures the wood blank stays in place.

| Modification | Purpose |

|---|---|

| Tool Rest | Supports woodturning tools |

| Cutting Tools | Carbide-tipped or HSS tools for cutting wood |

| Dust Collection | Collects wood dust and debris |

| Speed Control | Variable speed control for different woods |

Mastering Speed And Feed Rates

Turning wood on a metal lathe can be tricky. Mastering speed and feed rates is essential for smooth, precise cuts. Each wood type requires different speeds and feeds. Let’s dive into the optimal settings for various wood types and how to adjust feed rates for best results.

Optimal Speeds For Different Wood Types

Choosing the right speed is crucial. It prevents the wood from burning and ensures a clean cut. Here are some optimal speeds for different wood types:

| Wood Type | Optimal Speed (RPM) |

|---|---|

| Softwoods (e.g., Pine, Cedar) | 1000-1500 |

| Hardwoods (e.g., Oak, Maple) | 500-1000 |

| Exotic Woods (e.g., Mahogany, Ebony) | 800-1200 |

Softwoods need higher speeds. Hardwoods require slower speeds to avoid burning. Exotic woods need moderate speeds.

Adjusting Feed Rates For Smooth Cuts

Feed rate affects the finish quality. Adjusting it properly ensures smooth cuts. Here are some tips:

- Slow feed rates are best for hardwoods. It prevents tearing.

- Faster feed rates work well with softwoods. It saves time.

- Use a steady hand to keep the feed rate consistent.

Using the right feed rate can make a big difference. It ensures a polished finish and reduces the need for sanding.

Experiment with different speeds and feed rates. Find what works best for your wood type and project. Happy turning!

Techniques For Precision And Symmetry

Turning wood on a metal lathe can be challenging. Achieving precision and symmetry is vital for beautiful and functional pieces. This section will cover techniques that help improve your woodturning skills on a metal lathe.

Using A Steady Rest For Stability

A steady rest is crucial for stability. It supports the wood, reducing vibrations. This tool ensures the piece stays in place during turning.

Here’s how to use it:

- Mount the steady rest onto the lathe bed.

- Adjust the fingers to touch the wood gently.

- Tighten the fingers to hold the wood firmly.

This setup provides a stable platform. It allows for smoother cuts and better precision.

Achieving Consistent Cuts

Consistency in cuts leads to symmetrical pieces. Follow these steps to achieve it:

- Start with a sharp tool. A dull tool causes rough cuts.

- Set the lathe to the correct speed. Faster speeds work for softer woods.

- Use a caliper to measure your cuts. Keep measurements uniform.

- Apply even pressure. This ensures the cuts are consistent.

These steps help in maintaining symmetry. Consistent cuts result in professional-looking pieces.

| Tool | Purpose |

|---|---|

| Steady Rest | Provides stability and support. |

| Caliper | Ensures uniform measurements. |

| Sharp Tool | Results in smoother cuts. |

Credit: turnedwoodenbowls.co.uk

Finishing Touches On A Metal Lathe

Achieving a perfect finish on wood turned on a metal lathe requires patience. The right techniques can make your project stand out. Here, we dive into the finishing touches that transform good work into great work.

Sanding Techniques For A Flawless Finish

Sanding is crucial for a smooth finish. Begin with coarse grit sandpaper. Gradually move to finer grits. This removes tool marks and smooths the wood.

- Start with 80-grit sandpaper.

- Move to 120-grit for a finer surface.

- Finish with 220-grit for a smooth touch.

Use the following steps:

- Turn the lathe on at a low speed.

- Hold the sandpaper against the spinning wood.

- Move the sandpaper along the wood’s length.

Always wear a mask to avoid inhaling dust. Safety is important. Sanding well ensures a smooth base for the finish.

Applying Finishes On The Lathe

Finishing enhances the wood’s look and protects it. While the lathe spins slowly, apply the finish.

- Use a clean cloth to apply oil or wax.

- Ensure even coverage over the entire piece.

- Buff with a soft cloth for a shine.

Common finishes include:

| Finish Type | Properties |

|---|---|

| Mineral Oil | Easy to apply, food-safe |

| Beeswax | Natural, gives a soft sheen |

| Lacquer | Durable, high-gloss |

Apply multiple coats for a better finish. Let each coat dry before applying the next. This creates a durable and attractive surface.

Advanced Projects And Artistic Flair

Turning wood on a metal lathe opens up endless possibilities for advanced projects. Experienced turners can create intricate shapes and add artistic flair. This section will cover creating complex shapes and patterns and adding decorative elements.

Creating Complex Shapes And Patterns

Advanced turners can craft complex shapes on a metal lathe. Achieving precision is essential when creating intricate designs. Use specialized tools to carve detailed patterns. These patterns can include spirals, grooves, and flutes.

Here are some tips for creating complex shapes:

- Use a steady hand for uniform cuts

- Plan your design before starting

- Practice on scrap wood first

Creating complex shapes also involves using different lathe settings. Adjust the speed and feed rate based on the wood type. Experiment with various tools to achieve desired effects.

Adding Decorative Elements

Adding decorative elements enhances the beauty of turned wood projects. You can inlay different materials like metal or resin. This adds a unique touch to your work.

Here are some common decorative techniques:

- Inlaying metal or resin

- Adding carved details

- Using stains and finishes

Inlaying involves embedding materials into the wood surface. Carved details can include ornate patterns or textures. Stains and finishes add color and shine to the final piece.

Here’s a quick comparison of some decorative techniques:

| Technique | Materials | Effect |

|---|---|---|

| Inlaying | Metal, Resin | Unique, Eye-catching |

| Carving | Wood | Detailed, Artistic |

| Staining | Wood Stain | Colorful, Vibrant |

Experiment with different techniques to find your style. Combining methods can create stunning, intricate designs.

Maintenance And Troubleshooting

Turning wood on a metal lathe can be an enjoyable hobby. However, to keep your lathe performing well, regular maintenance and troubleshooting are crucial. This section will guide you through essential tips for maintaining your lathe and solving common issues.

Keeping Your Metal Lathe In Top Condition

Regular maintenance ensures your lathe operates smoothly. Follow these simple steps:

- Clean the lathe after each use. Remove wood shavings and dust.

- Lubricate moving parts frequently. Use the recommended lubricants.

- Check for loose bolts and screws. Tighten them as needed.

- Inspect the belts. Ensure they are not worn or cracked.

Performing these tasks extends the life of your lathe. It also ensures safer operation.

Common Issues And How To Resolve Them

Even with regular maintenance, issues can arise. Here are some common problems and solutions:

| Issue | Cause | Solution |

|---|---|---|

| Excessive vibration | Unbalanced wood or loose parts | Balance the wood and tighten all parts |

| Inaccurate cuts | Dull cutting tools | Sharpen or replace the tools |

| Motor overheating | Overloaded motor or poor ventilation | Reduce load and improve ventilation |

Addressing these issues promptly prevents further damage. It also ensures your projects turn out perfectly.

Credit: www.youtube.com

Frequently Asked Questions

Can You Turn Wood In A Metal Lathe?

Yes, you can turn wood on a metal lathe. Ensure you use proper tools and take safety precautions.

What Speed Do You Turn Wood On A Lathe?

Turn wood on a lathe at speeds between 500 to 4000 RPM. Softer woods need lower speeds, harder woods higher. Always prioritize safety and follow the lathe manufacturer’s guidelines.

Is A Metal Lathe The Same As A Wood Lathe?

No, a metal lathe is not the same as a wood lathe. Metal lathes handle harder materials, whereas wood lathes are for softer, wood materials. Metal lathes offer higher precision and durability.

Can You Turn Wet Wood On A Lathe?

Yes, you can turn wet wood on a lathe. Wet wood is often easier to shape and produces less dust.

Conclusion

Mastering the art of turning wood on a metal lathe opens up endless creative possibilities. This skill combines precision and artistry, making it highly rewarding. Whether you are a hobbyist or a professional, incorporating woodturning techniques enhances your craftsmanship. Start exploring this versatile craft today and elevate your projects.