Table of Contents

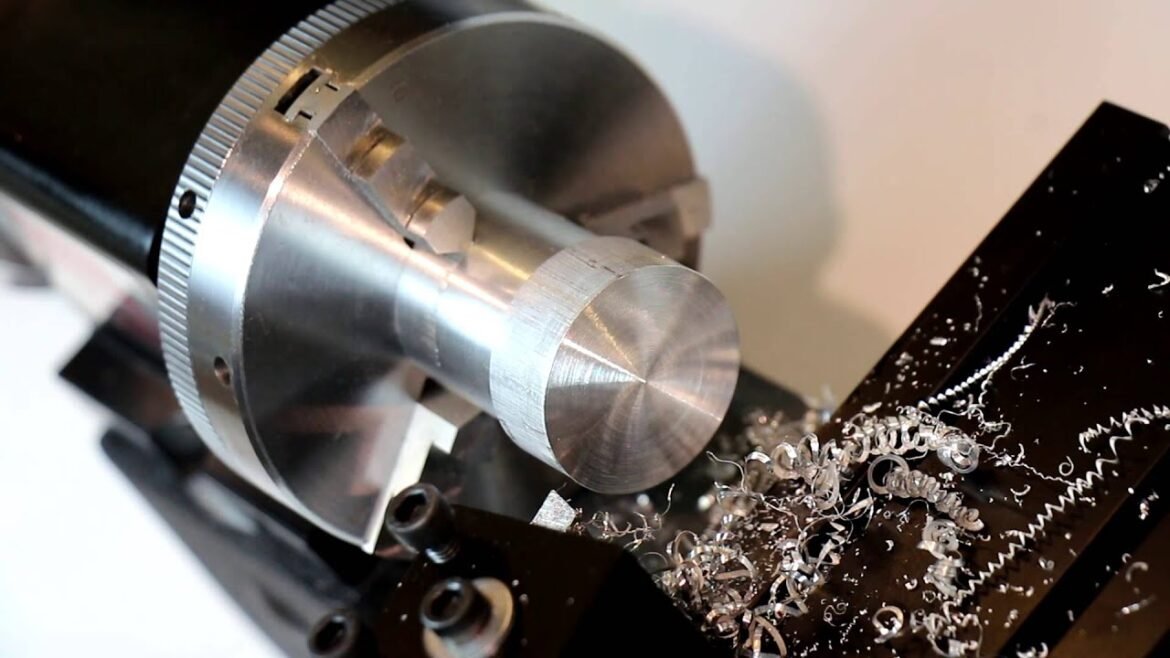

Turning metal on a lathe involves shaping a metal workpiece by rotating it against a cutting tool. This process produces precise cylindrical parts.

Lathe turning is a fundamental machining process used in various industries. It offers high precision and versatility, making it ideal for creating complex shapes and smooth finishes. Metals like aluminum, steel, and brass are commonly turned on lathes. Proper setup and tool selection are crucial for achieving optimal results.

Safety measures, including wearing protective gear and securing the workpiece, are essential. Understanding the basics of lathe operation can significantly enhance your metalworking skills. Mastery of this technique opens up a wide range of possibilities for both hobbyists and professionals in manufacturing and engineering fields.

The Art Of Metal Turning

A lathe is an ancient tool. It dates back to 1300 BC. The lathe rotates the metal. This helps in cutting and shaping. Over time, lathes have improved. Today, they are powerful machines. They are used in many industries. Metal turning on a lathe is a key skill. It creates parts for cars, planes, and tools. Knowing how to use a lathe is very important. It requires practice and patience.

Several tools are crucial for metal turning. A cutting tool is essential. It shapes the metal. A boring bar is needed. It helps make holes. A parting tool is also important. It cuts off finished pieces. A tool holder keeps tools steady. Safety goggles protect your eyes. A caliper measures the metal. These tools make metal turning precise and safe.

Preparing The Lathe For Metal Turning

Preparing the lathe for metal turning involves securing the workpiece and setting up the appropriate cutting tools. Ensure all safety measures and adjustments are in place for precise and efficient operation. Proper alignment and maintenance of the lathe are essential for achieving accurate metal turning results.

Initial Setup: Safety And Calibration

Always wear safety goggles and gloves. Check that your workspace is clean. Ensure the lathe is on a stable surface. Verify that all parts are securely attached. Adjust the tool rest to the correct height. Make sure the lathe bed is clean. Calibrate the lathe according to the manual. Double-check all calibration settings before starting. Confirm that the emergency stop button works.

Choosing The Right Chuck And Jaws

Select a chuck that fits your lathe. Choose jaws that match the metal piece size. Attach the chuck tightly to the spindle. Make sure the jaws grip the metal firmly. Use a chuck key to secure the jaws. Check the alignment of the metal piece. Ensure no wobbling occurs. Adjust the jaws if necessary. Test the setup by rotating the spindle.

Material Selection And Preparation

Different metals have unique properties. Aluminum is lightweight and easy to turn. Steel is strong but can be harder to work with. Brass offers good machinability and looks nice. Copper is soft and conducts heat well. Titanium is light and strong but expensive. Each metal has its own uses and benefits. Choose the right metal for your project.

Ensure the metal is clean before turning. Dirt and oil can damage tools. Use a degreaser to clean the metal. Measure the metal stock accurately. Cut the metal to the needed size. Secure the metal in the lathe properly. Make sure it is tight and aligned. Use safety goggles and gloves. Safety first when working with metal. Always check your tools before starting. Sharp tools give better results.

Credit: turnedwoodenbowls.co.uk

Precision Techniques In Metal Turning

Mastering metal turning on a lathe ensures precision and smooth finishes. Fine-tuned techniques enhance accuracy, resulting in high-quality components.

Mastering Cutting Speeds And Feeds

Picking the right cutting speeds and feeds is key. It helps in getting a smooth finish. Too fast and you get rough edges. Too slow and it wastes time. Always check the material type first. Different metals need different speeds. For example, steel needs a slower speed compared to aluminum. Always use a sharp tool for better results.

Advanced Tool Angles And Positioning

Tool angles matter a lot in metal turning. A slight change can make a big difference. Keep the tool angle correct for the material. Positioning the tool right also helps. It should be at the center height. This avoids vibrations and gives a better finish. Always check the tool’s position before starting. Small adjustments can improve the quality a lot.

Cutting Tool Essentials

Master the art of turning metal on a lathe with essential cutting tools. Achieve precision and efficiency in every project. Proper tools ensure smooth operations and high-quality finishes.

Selecting The Right Cutting Tools

Picking the right cutting tools is crucial. High-speed steel tools are great for beginners. They are easy to shape and sharpen. Carbide-tipped tools last longer and cut better. They are perfect for harder metals. Diamond-tipped tools are the best for smooth finishes. Always match the tool to the material.

Maintenance And Care Of Cutting Tools

Cleaning the cutting tools after use is important. Remove all metal chips and debris. Sharpen the tools regularly to keep them efficient. Store them in a dry place to prevent rust. Use protective covers if available. Lubricate the tools to keep them in top condition. Proper care extends the tool’s life.

Executing The Turning Operation

Start by securing the metal piece in the lathe chuck. Ensure it is tight and centered. Select the appropriate cutting tool for your task. Next, set the lathe speed according to the material being turned. Engage the tool with the metal slowly. Take light cuts to avoid breaking the tool.

Use coolant to keep the tool and metal cool. Regularly check your progress. Adjust the tool position as needed. Stop the lathe to measure your work. Repeat these steps until you achieve the desired shape.

Creating complex shapes requires specialized tools. Use a form tool for intricate patterns. For threading, select a thread cutting tool. Set the lathe to the correct thread pitch. Engage the tool with the metal slowly. Make sure to use multiple passes for deep threads.

Monitor the thread cutting closely. Use calipers to measure the thread depth. Repeat the process until the desired thread is achieved. Always ensure safety by wearing protective gear.

Finishing Touches In Metal Turning

The surface finish is very important. It makes the metal smooth and shiny. A smooth surface looks nice and works better. Use a fine-grit sandpaper to polish the metal. Take your time and move slowly.

Precision measurements are key. Use a caliper or micrometer. These tools check the size of the metal. Make sure the measurements are correct. This helps the metal fit perfectly in other parts.

Post-turning treatments make the metal stronger. Heat treatment is one method. It involves heating the metal and then cooling it. This makes the metal hard and durable. Use oil or water to cool the metal quickly.

Another treatment is coating. Apply a protective layer to the metal. This prevents rust and damage. Common coatings include paint, oil, and zinc. Choose the best coating for your project.

Credit: www.glue-it.com

Troubleshooting Common Lathe Issues

Mastering the art of turning metal on a lathe requires addressing common issues. Solving vibration, chatter, and tool wear ensures precision. Proper maintenance and alignment enhance performance and longevity.

Diagnosing And Fixing Common Errors

Lathe issues can be frustrating. Check if the tool is sharp. A dull tool won’t cut well. Look at the workpiece alignment. It should be straight. Listen for strange noises. This could mean a problem. Feel for excessive vibrations. This could cause errors. Inspect the belt tension. Loose belts slip. Ensure the speed settings are correct. Wrong speeds can damage parts.

Preventive Measures And Best Practices

Always clean the lathe after use. Dirt causes wear. Lubricate moving parts regularly. This keeps them smooth. Check the tool sharpness before starting. Sharp tools work best. Align the workpiece properly. Misalignment causes errors. Use the right speed settings. Each material needs a specific speed. Tighten all bolts and screws. Loose parts can be dangerous.

Advancing Your Skills

Mastering the art of turning metal on a lathe hones precision and craftsmanship. Enhance your skills by exploring advanced techniques and tool uses. Elevate your projects with smoother finishes and intricate designs.

Projects To Challenge Your Abilities

Trying new projects can sharpen your lathe skills. Make a custom pen using different metals. Create a chess set with unique designs. These projects push your creativity and precision. Each step teaches you something new.

Experiment with different tools and techniques. Use a variety of cutting tools. Test your skills with intricate designs. This helps improve your control and accuracy. The more you practice, the better you get.

Continued Learning And Community Engagement

Joining a community helps you learn faster. Share your projects with others. Get feedback and advice. Many online forums and local clubs exist. They offer support and inspiration.

Attend workshops and classes. Learn from experienced turners. Watching videos also helps. Keep up with new techniques and tools. This keeps your skills fresh and up-to-date.

Credit: elemetgroup.com

Frequently Asked Questions

Can You Turn Metal On A Lathe?

Yes, you can turn metal on a lathe. Lathes are commonly used for shaping, cutting, and finishing metal.

What Direction Does A Metal Lathe Turn?

A metal lathe typically turns in a counterclockwise direction. This allows for optimal cutting and machining.

What Speed Should A Metal Lathe Turn?

The ideal speed for a metal lathe varies. For mild steel, use 60-100 RPM. For aluminum, aim for 200-300 RPM.

What Are The 5 Main Parts Of A Metal Turning Lathe?

The 5 main parts of a metal turning lathe are the bed, headstock, tailstock, carriage, and the spindle.

Conclusion

Mastering lathe techniques can elevate your metalworking skills. Practice and precision lead to impressive results. Stay patient and focused. With dedication, you’ll create stunning, high-quality metal pieces. Keep experimenting and refining your skills. Happy turning!