Table of Contents

A Segmented Woodturning Calculator helps woodturners calculate the precise dimensions and angles for segmented wood projects. It ensures accuracy and efficiency in creating intricate designs.

Segmented woodturning involves assembling multiple pieces of wood to create intricate patterns and shapes. Precision is crucial in this craft to ensure all segments fit perfectly. A Segmented Woodturning Calculator simplifies this process by providing exact measurements and angles. This tool is invaluable for both novice and experienced woodturners, ensuring each project is executed flawlessly.

By using the calculator, you save time and reduce errors, allowing you to focus on the creative aspects of woodturning. Accurate calculations lead to beautiful, professional-quality pieces that showcase the art of segmented woodturning.

Introduction To Segmented Woodturning

Segmented turning is a beautiful craft. It involves joining multiple pieces of wood. Each piece is carefully cut and glued. This process creates stunning patterns and designs. Craftsmen often use a segmented woodturning calculator. It helps in planning and precision. Patterns can be complex or simple. The beauty lies in the details.

Precision makes woodturning more beautiful. Each piece fits perfectly. This reduces waste and saves time. The finished product looks professional. Calculators help ensure accurate measurements. This leads to better results. Precision is key in segmented woodturning. It enhances both beauty and quality.

Credit: www.jackmanworks.com

Essential Tools For Segmented Turning

A good lathe is the heart of segmented turning. Pick a lathe that can handle larger pieces. Ensure it has variable speed control. This feature helps you work with different wood types. Stability is crucial. A heavy lathe reduces vibrations. Look for one with a strong motor. It should have at least 1 horsepower.

Accurate measurements are key in segmented turning. A digital caliper provides precise readings. Use a protractor for angle measurements. Dividers are useful for marking equal distances. Invest in a good ruler and tape measure. Both should be durable and easy to read.

Designing Segmented Patterns

Start with a simple design. Use geometric shapes like circles and squares. Mix different types of wood for contrast. Keep the grain direction consistent. Ensure each segment fits well with the next. Measure twice, cut once for accuracy. Use glue sparingly to avoid mess. Sand each piece before assembly. Plan your design on paper first. Check for gaps between segments. Adjust as needed for a perfect fit. Your design will look neat and professional.

Many tools help you see your design before cutting. Woodturning Design is a good option. Segmented Project Planner offers easy-to-use features. SketchUp also works well for wood projects. Draw your pattern on the software first. Adjust colors and shapes as needed. Print your design for reference. This helps you avoid mistakes. Your project will be more successful. Visual tools save time and improve accuracy. They make complex designs simpler.

Credit: www.woodturnersresource.com

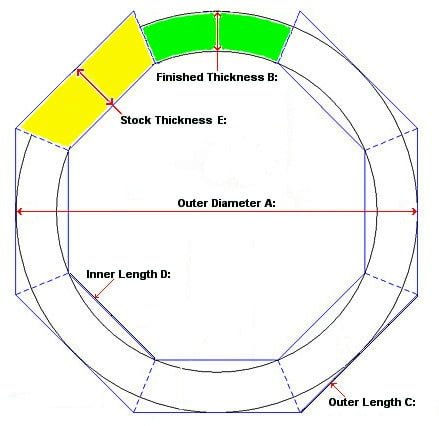

Calculating Segment Dimensions

Segmented woodturning involves creating beautiful wood pieces. Calculating segment dimensions is key. Each segment must fit perfectly. You need to know the diameter and number of segments. The math can be tricky but is essential for success.

Use the formula: Circumference = π x Diameter. Divide the circumference by the number of segments. This gives you the length of each segment. Ensuring accurate measurements is crucial.

A segmented woodturning calculator helps simplify the process. Enter the diameter and number of segments. The calculator gives you the exact segment size. This tool saves time and reduces errors. It’s a handy resource for woodturners.

Selecting Wood And Materials

Choose hardwoods like maple, oak, and cherry. These woods are durable and look beautiful. Softwoods like pine can also be used. They are easier to work with but less durable. Mix different types of wood for a unique look. Always check for cracks or defects before using any wood.

Use PVA glue for strong bonds. It dries clear and is easy to clean. Epoxy is another good choice for its strength and water resistance. For finishes, oil finishes like linseed oil are popular. They bring out the wood’s natural beauty. Polyurethane provides a tough, water-resistant finish. Always apply finishes in a well-ventilated area.

Credit: woodturnerscatalog.com

Cutting Techniques For Precision

Precise cuts require careful setup. Use a sharp blade to avoid splinters. Ensure the wood is securely clamped. Measure twice and cut once. Always double-check your angles. Keeping the saw clean will also help.

Laser guides can enhance accuracy. Try using a jig for repetitive cuts. Practice scoring the wood lightly before the final cut. Featherboards can keep the wood steady. Consider zero-clearance inserts to reduce tear-out.

Assembling Segmented Projects

Choose the right glue for your project. Wood glue works best for most cases. Spread the glue evenly on each segment. Use a brush to cover all surfaces.

Place the segments together. Ensure they fit snugly. Use clamps to hold the pieces in place. Tighten the clamps but not too much. Excess glue should squeeze out. Wipe off the extra glue quickly.

Check the alignment of each segment. Use a ruler to ensure straight lines. Adjust the pieces if they shift. A small tap can help align them. Hold the segments until the glue sets.

Use a jig for better alignment. Jigs hold the pieces firmly. This ensures perfect alignment. Double-check everything before the glue dries. This keeps your project looking great.

Finishing Touches

Sanding is crucial for a smooth surface. Start with coarse grit paper. Progress to finer grits slowly. Always sand with the grain. This avoids scratches. Use a soft cloth to remove dust. Repeat the process until satisfied. A smooth finish enhances the wood’s beauty.

Choose a suitable finish for your wood. Oil finishes penetrate deeply. They enhance the wood’s natural color. Varnish offers a shiny, protective layer. Apply thin, even coats. Allow each coat to dry completely. Sand lightly between coats. This ensures even application. Use a clean brush or cloth. Always work in a well-ventilated area. This ensures safety and proper drying.

Troubleshooting Common Issues

Gaps and misalignments can ruin your project. Always check measurements twice before cutting. Sand pieces to ensure smooth edges. Use clamps to hold pieces tightly together. Apply glue evenly to avoid gaps. Let glue dry completely before moving to the next step. If gaps appear, fill them with wood filler. Sand the area again for a smooth finish.

Glue errors can be frustrating. Remove excess glue with a damp cloth quickly. Sand away any dried glue spots. Use a sharp chisel to clean tight corners. For better results, always use the right type of glue. Clean your tools after each use to avoid mistakes next time.

Innovations In Segmented Woodturning

New tools are making woodturning easier. Laser-guided tools help in making precise cuts. Computer-aided design (CAD) is now used for designing. 3D printing helps in creating complex shapes. Smart sensors can detect issues early. Automated lathes do most of the work for you. Virtual reality (VR) can teach beginners easily. These technologies save time and reduce mistakes.

The future of segmented turning looks bright. AI will help in designing better patterns. Robots will handle repetitive tasks. Green technologies will reduce waste. Online communities will share knowledge quickly. Customizable tools will fit any project. Mobile apps will offer on-the-go advice. These advancements promise exciting times ahead.

Frequently Asked Questions

What Is The Formula For A Segmented Bowl?

To calculate a segmented bowl, use the formula: Total Segments = Desired Diameter / Segment Width. Multiply the result by the segment height.

What Is The Angle Of A Segmented Bowl?

The angle of a segmented bowl varies. It depends on the number of segments and the design. Typically, segments are cut at specific angles to fit together. For a bowl with 12 segments, each angle is 15 degrees.

What Is A Segmented Woodturning Calculator?

A segmented woodturning calculator helps design and measure woodturning projects. It ensures precise segment dimensions and angles for seamless assembly.

How Does A Segmented Woodturning Calculator Work?

It calculates segment dimensions and angles based on user input. Enter the desired project size and number of segments for accurate results.

Conclusion

Mastering segmented woodturning is now easier with our calculator. It ensures precise measurements and perfect designs. Enhance your woodturning projects by utilizing this essential tool. Save time, reduce errors, and achieve professional results. Try our segmented woodturning calculator today and elevate your craftsmanship to new heights.