Table of Contents

A Segmented Metal Turning Calculator helps determine the precise dimensions and angles for creating segmented wood turning projects. It ensures accuracy in measurements and angles for intricate designs.

A Segmented Metal Turning Calculator is an essential tool for woodturners and metalworkers. It aids in crafting precise, intricate designs by calculating the exact dimensions and angles needed. This tool is invaluable for ensuring each segment fits perfectly, leading to smoother, more professional outcomes.

Using this calculator enhances efficiency and reduces material waste by providing accurate measurements. It simplifies the complex process of creating segmented projects, making it accessible even for beginners. The calculator streamlines the planning phase, allowing you to focus on the creative aspects of your work. Its ease of use and accuracy make it a must-have for any serious woodturner or metalworker.

Introduction To Segmented Metal Turning

Precision is key in metalworking. Even tiny errors can ruin a project. Using the right tools is essential. A Segmented Metal Turning Calculator helps achieve accurate results.

Metalworking requires exact measurements. This ensures parts fit perfectly. Precision tools like a metal turning calculator are vital. They help avoid costly mistakes. Correct measurements save time and resources.

A Segmented Metal Turning Calculator is a tool. It helps in calculating various parameters. These parameters include speeds and feeds. It ensures the workpiece is turned accurately. The calculator is easy to use. It improves efficiency and precision.

Essential Features Of Turning Calculators

Segmented Metal Turning Calculators offer precision in calculating feed rates, cutting speeds, and depths of cut. These tools enhance efficiency and accuracy in metalworking projects.

Material Specifications Input

Users can input metal types like steel, aluminum, or copper. The calculator adjusts settings based on the material. This ensures the best cutting speed. Harder metals need different settings than softer ones. Users can select the metal’s hardness and tensile strength. This helps in achieving accurate results. The input interface is user-friendly.

Cutting Parameters Adjustment

Users can change cutting speed, feed rate, and depth of cut. This makes the tool versatile for many tasks. Speed adjustments help in preventing tool wear. The correct feed rate ensures smooth operations. Users can also set the depth based on their needs. All settings are easy to change with simple controls.

Benefits Of Using A Turning Calculator

Segmented Metal Turning Calculator enhances precision, saves time, and reduces material waste. Optimize your metalworking projects with ease and accuracy.

Enhanced Accuracy

A turning calculator helps in achieving higher precision in metal turning. It ensures that every cut is made with exact measurements. This tool reduces human error, making the process more reliable. Enhanced accuracy leads to better quality finished products. Using a calculator also helps in maintaining consistent performance. This is important for producing identical parts.

Time And Cost Savings

Using a turning calculator reduces waste. This means less material is thrown away. It also helps in optimizing the cutting process. As a result, there is a significant reduction in production time. Less time spent means lower labor costs. All these factors contribute to saving money. The tool also minimizes the need for reworking parts. This further saves both time and resources.

Credit: www.pinterest.com

Types Of Metal Turning Operations

Facing is a common metal turning operation. It smoothens the end of a workpiece. Contouring shapes the surface of a metal. Both are important for precision work. They make sure the metal fits the desired design. Many industries rely on these techniques. They improve both form and function.

Grooving involves cutting a narrow groove into the metal. It helps in creating rings or slots. Parting cuts a piece of metal into two parts. This operation is useful for separating sections. Both are key in metalworking. They offer flexibility in design and function.

Calculating For Different Materials

Easily calculate precise measurements for segmented metal turning projects. Optimize efficiency and accuracy with this specialized calculator designed for various materials. Enhance your metalworking process with seamless, accurate computations.

Adapting To Material Properties

Different materials have unique properties. Hardness and toughness are key factors in metal turning. Softer metals are easier to turn. Harder metals need more power and better tools.

Tough materials can wear tools quickly. Adjusting speed and feed rates helps. Using a segmented metal turning calculator is essential. It optimizes settings for each material. This ensures better results and longer tool life.

Adjusting For Hardness And Toughness

Harder materials need lower speeds. This reduces tool wear. Tough materials need slower feed rates. This prevents tool damage. The calculator helps find the best settings. It saves time and improves efficiency.

Always check material properties first. Use the right tool for the job. The calculator makes this easy. Input the material type, and get the best settings.

Understanding Tool Geometry

Tool shape affects the quality of metal turning. A well-designed tool shape reduces cutting forces. Sharp tools make cleaner cuts. Rounded tools are used for finishing. The right tool shape improves efficiency.

Tool wear impacts life expectancy. Frequent use wears out tools faster. High-quality materials last longer. Proper maintenance extends tool life. Regular sharpening keeps tools effective. Using coolant can reduce wear.

Software Integration

Linking a segmented metal turning calculator with CAD/CAM systems is essential. This connection allows for seamless design and manufacturing. The calculator receives data directly from the CAD software. This ensures accurate and efficient toolpath generation. It also minimizes errors and saves time. Users can easily adjust parameters in real-time. This creates a smooth workflow from design to production.

Data synchronization across platforms ensures that all systems work together. The segmented metal turning calculator must sync data with other software. This makes sure that information is consistent and up-to-date. Synchronization helps in maintaining accuracy. It also aids in reducing discrepancies between different platforms. This leads to better coordination and improved productivity.

Credit: letsfab.in

Case Studies: Success Stories

Many factories use the Segmented Metal Turning Calculator. It helps in making precise parts for machines. One company used it to improve the quality of their metal parts. They saw a 20% increase in production.

Using the calculator, manufacturers can save time and money. Workers can make fewer mistakes. The calculator helps in planning the work better. This leads to smoother operations. Machines work faster and with greater accuracy.

Choosing The Right Calculator For Your Needs

Different models offer various features. Some are simple, while others are advanced. Basic models are good for small tasks. They are easy to use and understand. Advanced models have more features. They can handle complex calculations. Look for durability and accuracy in any model. Price can be a factor too. Expensive ones often have more features.

Accuracy is key in a calculator. Make sure it gives correct results. Ease of use is also important. It should be user-friendly. Durability ensures it lasts long. Price is a factor. Choose one that fits your budget.

Credit: www.linkedin.com

Frequently Asked Questions

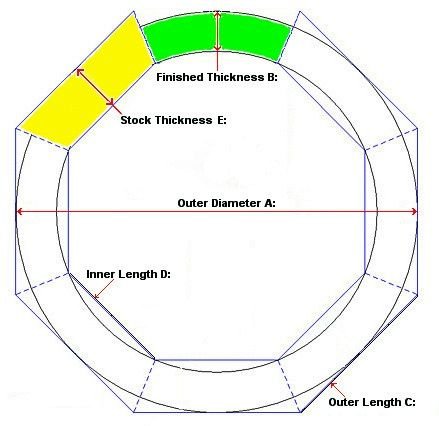

What Is The Formula For A Segmented Bowl?

To create a segmented bowl, use the formula: Diameter = (2 × Radius × π) / Number of Segments. This calculates the width of each segment.

How Do You Calculate Sfm For Turning?

To calculate SFM for turning, use the formula: SFM = (π * Diameter * RPM) / 12. Measure the diameter in inches and RPM in rotations per minute.

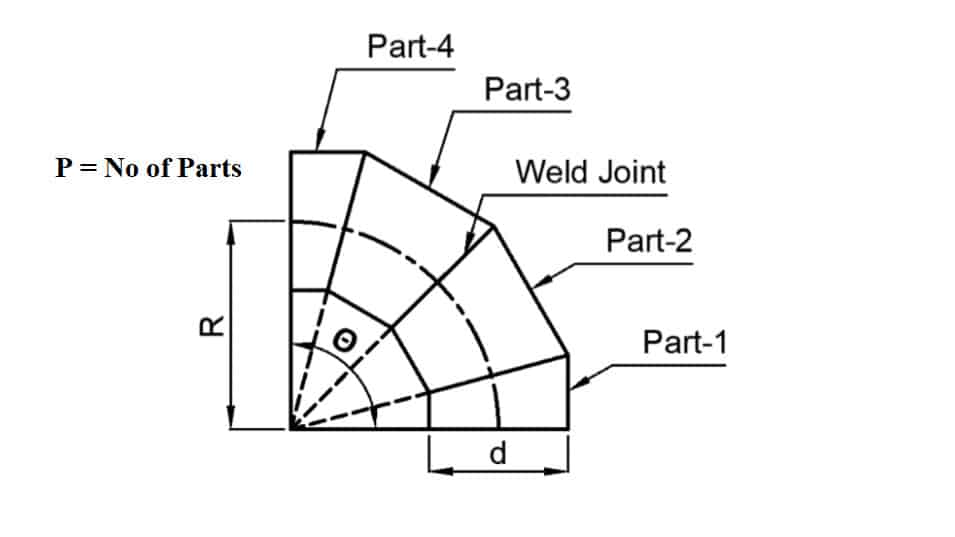

What Is A Segmented Metal Turning Calculator?

A segmented metal turning calculator helps machinists plan precise cuts. It calculates dimensions, angles, and material removal rates. This tool ensures accurate and efficient machining.

How Does A Segmented Metal Turning Calculator Work?

It uses input parameters like material type, segment dimensions, and cutting speed. The calculator processes these inputs to provide optimal cutting conditions, ensuring precision.

Conclusion

Mastering segmented metal turning becomes easier with the right calculator. Enhance precision and efficiency in your projects. Utilize this tool for accurate measurements and smoother operations. Stay ahead in your craft by integrating advanced techniques. Elevate your metalworking skills and achieve superior results.

Thank you for reading!