Table of Contents

To troubleshoot common wood lathe issues at home, you can follow these steps. First, address any vibration that you may be experiencing by securely tightening any loose parts and ensuring stable mounting. Second, rectify any unusual noises by inspecting and replacing any worn components such as bearings or belts. Finally, improve any inaccuracies by sharpening tools, aligning components, adjusting the tool rest, and tightening any locking screws that may be loose.

Regular maintenance, such as cleaning, lubricating with oil, and following the machine tool manual, can prevent many problems. Always consult the lathe’s manual for specific issues and machine tool care, and consider professional help for complex repairs.

3 Wood Lathe Maintenance Essentials

Essential Components

Wood lathes contain critical components such as the headstock, tailstock, tool rest, bed, and quill. The headstock, a machine tool accessory, houses the motor and spindle responsible for rotating the wood piece. The tailstock, an accessory, supports the other end of the wood piece, ensuring stability during turning for optimal performance. The tool rest, an accessory, provides a platform for holding cutting tools while shaping the wood. Lastly, the bed is the base where all these components and accessories are mounted.

Understanding these parts and accessories is crucial in executing preventive maintenance effectively. Regularly cleaning and lubricating these components and accessories can prevent friction, wear, and tear, ensuring smooth operation over time.

Common Issues

Without proper maintenance, wood lathes can encounter issues like rust formation on metal parts due to exposure to moisture or inadequate lubrication. Worn-out bearings or belts may also lead to vibration during operation, affecting precision in woodworking projects.

Learning about these common problems prepares you for proactive measures through preventive maintenance techniques such as applying rust inhibitors and replacing worn-out parts promptly.

Costly Repairs Prevention

Preventive maintenance is pivotal in avoiding costly repairs by addressing potential issues before they escalate into major problems. You can significantly extend your wood lathe’s lifespan by regularly inspecting key components for signs of wear or damage and performing routine cleaning and lubrication tasks.

Personal Thought: I find investing time in preventive maintenance rewarding because it saves money and ensures that my woodworking projects proceed smoothly without unexpected interruptions.

Critical Practices for Effective Wood Lathe Care

Regular Cleaning Routine

Implement a regular cleaning routine to maintain preventive maintenance for wood lathes. Wipe down the lathe after each use, removing any wood shavings and dust that can accumulate. Use a brush or compressed air to clean hard-to-reach areas, ensuring no debris interferes with the machine’s performance.

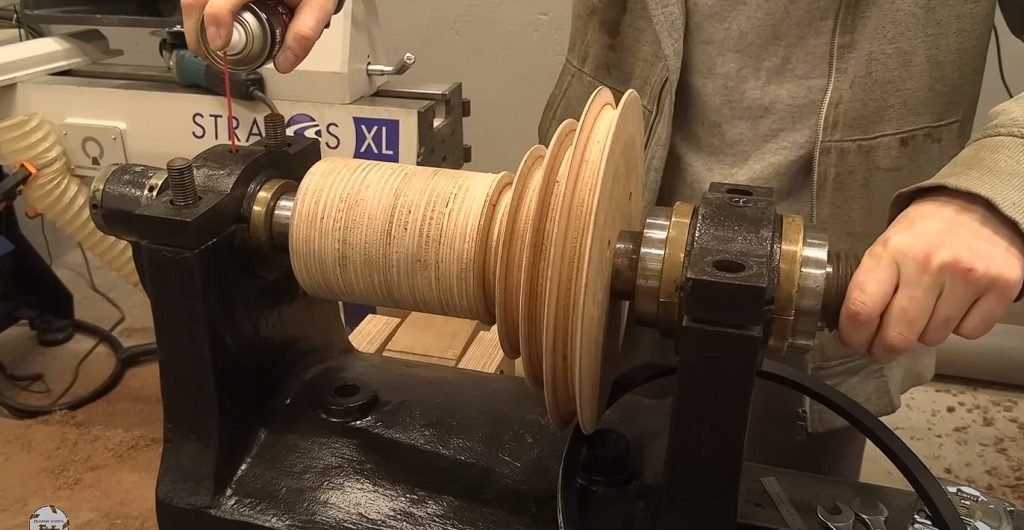

It’s also essential to lubricate moving parts regularly to prevent wear and tear. Apply a small amount of wood lathe oil on the bedways, tailstock, and tool rest banjo. This helps reduce friction and keeps the components running smoothly. Inspect belts and pulleys for any wear or damage during your cleaning routine.

Proper Storage and Protection

When not in use, store your wood lathe in a dry environment away from direct sunlight. Moisture can lead to rusting of metal parts, while excessive exposure to sunlight can cause wooden components to warp or crack over time. When not in use, they cover the lathe with a breathable fabric, providing extra protection against dust buildup.

Develop Good Habits Using sharp tools is essential for both safety and efficiency when operating a wood lathe. Dull tools require more force, which can strain the machine andse the risk of accidents. Furthermore, avoid subjecting your lathe to excessive strain by working within its recommended capacity limits.

Dedicating specific days to maintenance tasks helps me consistently care for my wood lathe.

Regular Cleaning and Inspection Routines

Effective Cleaning Techniques

To maintain a wood lathe, it’s crucial to clean its various components regularly. Use a soft brush or toothbrush to remove dust and debris from the metal surfaces. Pay special attention to the bed rails, inside the bedways, and other intricate parts.

Regular cleaning not only keeps your wood lathe looking good but also prevents the accumulation of rust or dirt that could affect its performance. Removing dust and debris ensures that your lathe operates smoothly without any obstructions.

I find it helpful to dedicate a few minutes after each use for quick spot cleaning with a brush or cloth. This habit helps me keep my wood lathe in top condition without spending hours on extensive cleaning sessions.

Importance of Inspection

In addition to regular cleaning, inspecting various parts of your wood lathe is essential for preventive maintenance. Check the belts, pulleys, and other components for signs of wear and tear. Look for cracks, fraying, or abnormalities that could indicate potential issues.

Regular inspections allow you to identify problems before they escalate into more significant concerns. This proactive approach can save you time and money by addressing minor issues promptly rather than waiting for them to cause considerable damage.

I make it a point to inspect my wood lathe thoroughly at least once a month. This routine has helped me catch minor issues before they become major headaches.

Proper Lubrication Techniques for Peak Performance

Importance of Lubrication

Lubrication plays a crucial role in maintaining the smooth operation of your wood lathe. Proper lubrication helps reduce friction between moving parts, preventing wear and tear. It also ensures that the components function optimally over an extended period.

A well-lubricated wood lathe operates quietly and efficiently, enhancing its lifespan. The quill, bearings, and gears require regular lubrication to maintain their performance. Using the correct type of lubricant, oil or paste wax, is essential for optimal functionality.

Lubricants are regularly applied to prevent rust formation on metal parts and keep wooden surfaces smooth during operation. Compressed air can also be used to clean out debris before applying new lubricant, further improving performance.

Tips for Effective Lubrication

When applying oil-based lubricants, ensure you use a suitable viscosity grade recommended by the manufacturer for different parts. For paste wax application, spread a thin layer evenly across wooden surfaces to prevent overheating during prolonged use.

Remember to wipe off any excess lubricant after application to avoid attracting dust and debris that could affect your lathe’s performance over time. Following a maintenance schedule for relubricating specific components will help sustain peak operational efficiency.

Using high-quality paste wax has significantly improved the overall performance of my wood lathe. It reduces friction and provides long-lasting protection against moisture and corrosion on metal parts.

Ensuring Safe Operation Through Preventive Measures

Safety Features

Wood lathes are potent tools that can be hazardous if not used properly. Safety should always be a top priority when operating a wood lathe. One of the most important preventive measures is ensuring the lathe has appropriate safety features. These may include emergency stop buttons, protective shields, and automatic braking systems. Emergency stop buttons allow operators to shut down the machine quickly, while protective shields help prevent wood chips and debris from causing injuries.

It’s essential to familiarize yourself with these safety features and understand how they function before using a wood lathe. Wearing personal protective equipment such as safety goggles, ear protection, and dust masks can further minimize the risk of accidents or injuries during operation.

Implementing proper safety features protects individuals and contributes to the wood lathe’s overall smooth functioning by preventing potential damage caused by accidents or misuse.

Minimizing Accidents

Preventive maintenance is crucial in minimizing accidents and ensuring the safe operation of wood lathes. Regular inspection of belts, pulleys, and tool rests can help identify any signs of wear or damage that could lead to malfunctions or accidents during use.

Scheduling and Conducting Regular Maintenance

Creating a Maintenance Schedule

To ensure the longevity of your wood lathe, it’s crucial to schedule regular maintenance. Start by creating a simple maintenance schedule that outlines tasks based on their frequency and importance. For example, daily tasks may include cleaning the lathe bed and checking for any loose parts, while weekly tasks could involve inspecting belts and pulleys for wear.

It’s essential to prioritize maintenance tasks based on how frequently they need to be done and their impact on the overall operation of the wood lathe. For instance, regularly lubricating moving parts such as the tailstock quill or tool rest banjo can prevent premature wear and maintain smooth operation.

I find marking down all scheduled maintenance in a dedicated notebook or calendar helpful. This helps me stay organized and ensures that no essential task is overlooked. A visual record of completed maintenance provides a sense of accomplishment and a reference point for future checks.

Effective Strategies for Thorough Maintenance Checks

Inspect critical components such as the motor, power switch, belts, bearings, and other moving parts when conducting thorough maintenance checks. Look out for signs of excessive wear or damage that could affect performance or safety.

Consider using this opportunity to clean accessories like chucks or faceplates thoroughly. Dust accumulation over time can affect their balance and functionality during use. Moreover, paying attention to proper alignment during reassembly after cleaning can prevent potential issues during future projects.

In addition to following your wood lathe’s manual guidelines for preventive maintenance procedures, consider investing in quality tools for maintaining woodworking equipment like lathes.

Addressing Critical Inspection Areas

Headstock

The headstock is a critical area that requires close inspection. Check for unusual noise, vibration, or wobbling when the lathe runs. Look out for worn-out bearings or damaged pulleys affecting the lathe’s performance. The headstock components should be thoroughly cleaned and lubricated regularly to prevent issues.

Inspecting the headstock allows me to ensure that my wood lathe operates smoothly without any disruptions. I always pay attention to strange sounds or vibrations, which could indicate potential issues with the bearings or pulleys.

Tailstock

The tailstock is another crucial area where issues may arise if not scrutinized during preventive maintenance. Ensure it moves freely along the bed and locks securely when needed. Check for any signs of wear on the quill and spindle threads, as these can lead to inaccuracies in turning operations. Regularly clean and apply grease to keep the tailstock functioning optimally.

Keeping my tailstock well-maintained significantly improves my woodworking experience by ensuring precise and accurate results in every project.

Tool Rest

Inspecting the tool rest is essential for safe and efficient woodturning operations. Look for any signs of wear on its surface, cracks, or instability in its attachment to the lathe bed. Adjustments should be made if there are any deviations from its original position or alignment concerning the turning stock.

Regularly checking and maintaining my tool rest gives me peace of mind, knowing I can work safely without risking damage due to an unstable tool rest.

Electrical Components

Finally, inspecting electrical components such as wiring, switches, and connections is significant for safety during preventive maintenance activities.

Importance of Proper Cutting Speed and Tool Rest Maintenance

Setting Correct Cutting Speed

Setting the correct cutting speed is crucial for different wood and turning projects. Using the wrong speed can result in rough finishes, tool chatter, or even dangerous kickbacks. For softer woods, a higher cutting speed is suitable for smoother cuts, while harder woods require a slower cutting speed to prevent overheating the tools.

Maintaining a consistent cutting speed ensures the lathe operates efficiently and produces high-quality turned items. When determining the appropriate cutting speeds for specific wood types and turning tasks, it’s essential to refer to manufacturer guidelines or seek advice from experienced woodworkers.

Importance of Adjusted Tool Rest

Properly adjusted tool rest maintenance is equally crucial for safe and effective operation. The tool rest supports the chisel during turning, reducing vibrations and enhancing precision. Regularly inspecting and adjusting the tool rest helps prevent accidents caused by tools catching on uneven surfaces or improperly positioned rests.

A well-maintained tool rest also contributes to better control over woodturning operations, allowing woodworkers to execute intricate designs while minimizing fatigue efficiently. Ensuring that the tool rests securely throughout each project, wood lathe operators can work confidently without concerns about sudden movements or instability.

Conclusion: Maximizing Your Wood Lathe’s Lifespan and Efficiency

Incorporating preventive maintenance practices into your wood lathe care routine maximizes lifespan and ensures peak performance. Regularly cleaning, inspecting, and lubricating your equipment can prevent costly repairs and maintain safe operation. Scheduling regular maintenance and addressing critical inspection areas will further contribute to the longevity of your wood lathe. Proper cutting speed and tool rest maintenance are essential for efficient and safe woodworking. By following these preventive measures, you can extend the life of your wood lathe while optimizing its efficiency.

It’s time to implement these maintenance tips and witness the remarkable difference they make in your woodworking experience. Stay proactive in caring for your wood lathe; you’ll enjoy smoother operations and superior results. Keep creating with confidence!

Frequently Asked Questions

What are the essential practices for effective wood lathe care?

Regular cleaning, proper lubrication, and scheduled maintenance are essential for wood lathe care. Inspecting critical areas and ensuring safe operation also contribute to effective preventive maintenance.

How often should I conduct regular maintenance on my wood lathe?

It’s recommended to conduct regular maintenance every 3-6 months, depending on usage. This includes thorough cleaning, inspection of critical components, and re-lubrication as needed.

Why is proper cutting speed essential for wood lathe maintenance?

Maintaining the correct cutting speed prevents the lathe’s motor strain and ensures smooth operations. It also contributes to better tool performance and extends the lifespan of both tools and the lathe itself.

What are some standard lubrication techniques for wood lathes?

It is crucial to use high-quality oils or greases specifically designed for woodworking machinery. As per manufacturer recommendations, apply lubricants sparingly but regularly to pivot points, bearings, gears, and other moving parts.

How can I ensure safe operation through preventive measures?

Always follow the safety guidelines provided by the manufacturer. Regularly inspect safety features such as emergency stop buttons, guards, and protective devices. Maintain a clean workspace free from debris that could interfere with machine operation or cause accidents.