Table of Contents

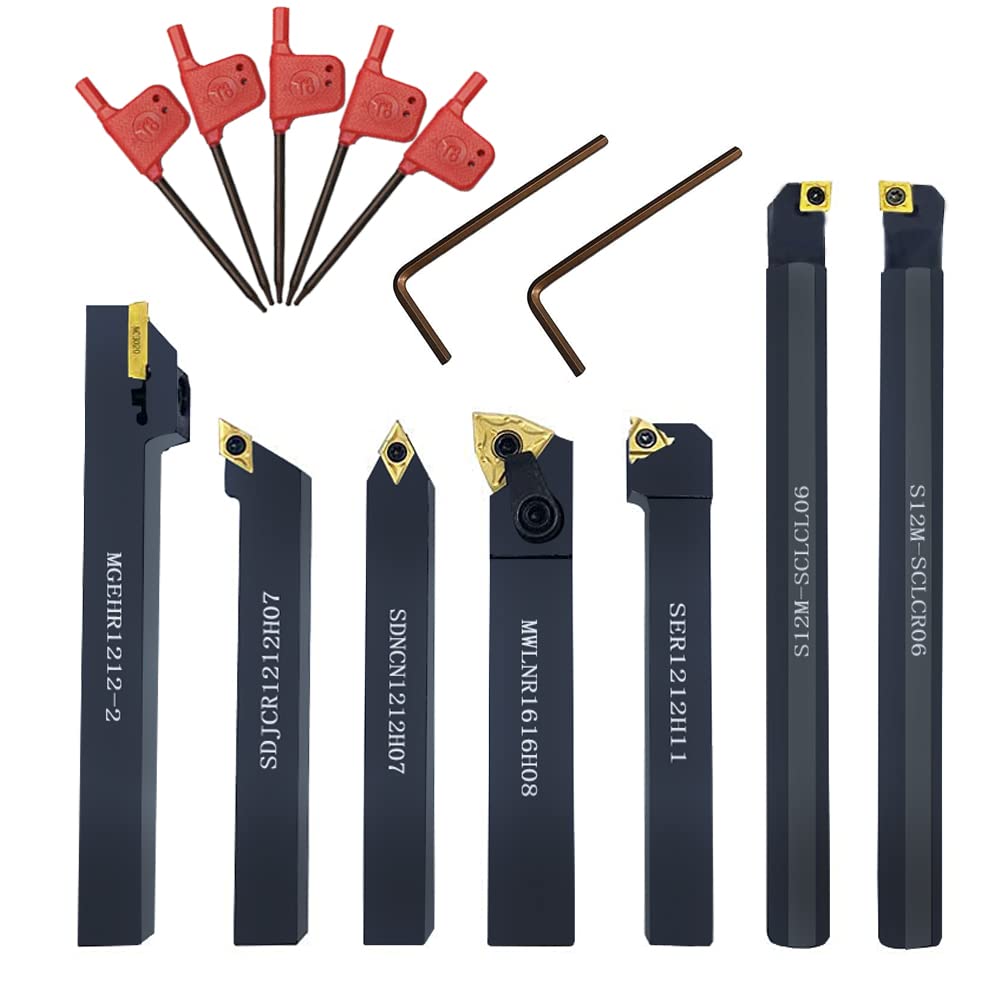

Metal turning tools for a lathe shape and finish metal workpieces. They provide precision and efficiency in machining tasks.

Lathe tools are essential in metalworking for their ability to create intricate designs and smooth finishes. These tools come in various types, including cutting, threading, and boring tools. Each type serves a specific purpose, ensuring versatility in metalworking projects. The choice of material for these tools, such as high-speed steel or carbide, impacts their durability and performance.

Proper maintenance and selection of the right tool for the job enhance productivity and extend tool life. Understanding the functions and benefits of different metal turning tools helps in achieving high-quality results in machining.

Introduction To Metal Turning Tools

Metal turning tools shape and cut metal on a lathe. These tools make precise and smooth cuts. They help in creating different shapes and sizes. Lathe operations require high precision. Proper tools are essential for this.

Cutting edges are the most crucial part. They need to be sharp and durable. The tool material affects the quality of the cut. Tool holders keep the tools steady during operations. Steady tools make accurate cuts. Coolants help in reducing heat. This prevents damage to the tools. Proper use of these components ensures high precision.

Credit: waykenrm.com

Types Of Metal Turning Tools

Cutting tools need to be sharp and durable. They must withstand high temperatures. Tools should resist wear and tear. A good tool has a smooth finish. It should also have a high hardness level.

Different materials have unique uses. High-speed steel is tough and used for general purposes. Carbide tools are harder and last longer. They are ideal for cutting hard materials. Ceramic tools resist heat well. They are perfect for high-speed cutting. Diamond tools are the hardest and cut the hardest materials.

Tool Geometry And Cutting Angles

The design of a tool affects its cutting ability. Proper geometry helps the tool cut better. Good design increases the tool’s life. Tool angles must be correct. Wrong angles can cause poor cuts. Sharp tools produce clean surfaces. Dull tools damage the workpiece.

Efficient cutting saves time and material. Tools should have the right cutting edge. The edge should be sharp and precise. Proper angles help in smooth cuts. This reduces effort and wear. Good cooling keeps the tool from overheating.

Material Considerations For Tools

Tool life depends on the material. High-speed steel (HSS) tools last long. Carbide tools offer better wear resistance. Ceramic tools resist heat well. The right material makes tools last longer.

HSS is good for general use. Carbide is best for hard metals. Ceramic works well at high speeds. Choosing the right tool material is essential. It affects the quality of work. It also impacts tool longevity.

Tool Holders And Mounting

Tool holders and mounting systems enhance precision for metal turning tools on a lathe. Secure attachments ensure consistent, high-quality results.

Ensuring Tool Stability

Tool stability is crucial in metal turning. A stable tool reduces vibrations. This leads to better surface finishes. It also extends the tool life. Proper mounting is important. Always ensure the tool is tightly secured. The tool should not wobble or shift. This prevents accidents and errors. Using the right tool holder is essential for stability.

Quick Change Vs. Traditional Systems

Quick change systems save time. They allow for fast tool swaps. This is useful in busy workshops. Traditional systems are slower. They require more manual adjustments. Quick change systems can be more expensive. Traditional systems are usually cheaper. Both have their advantages. Choose based on your needs and budget.

Credit: www.penntoolco.com

Setting Up For Precision

Proper tool alignment ensures precise cuts. Always check the tool’s position before starting. Use a dial indicator to measure alignment. Adjust the tool rest to the correct height. The tool tip should be at the centerline of the lathe. This prevents uneven cuts and tool wear.

Calibration is key for precision work. Use gauge blocks to set accurate measurements. Verify the lathe’s spindle with a test bar. This ensures the spindle runs true. Regularly check and calibrate your tools. This maintains accuracy and prolongs tool life. Keep a log of calibration dates and results.

Coolants And Lubrication In Metal Turning

Coolants and lubricants are very important. They keep the tools cool and reduce wear. Proper cooling helps tools last longer. It also improves the quality of the work. Lubrication reduces friction. This makes cutting smoother and easier.

There are different types of coolants. Some are water-based. Others are oil-based. Water-based coolants are good for high-speed cutting. Oil-based coolants are better for slow-speed cutting.

Choosing the right coolant depends on many factors. These include the material being cut and the cutting speed. The type of tool also matters. Always check the manufacturer’s recommendations.

Advanced Metal Turning Tools

CNC tools are used in automated lathes. These tools make precise cuts possible. They work fast and save time. CNC tools are controlled by computers. This makes them very accurate. They can repeat the same cut many times. This ensures each piece is the same. Using CNC tools can reduce waste. They can also lower costs. Many industries use these tools. They are popular in car manufacturing. They are also used in aerospace. CNC tools are a big part of modern production.

Tool technology keeps getting better. New materials are used for tools. These materials last longer. They can cut harder metals. Tools are also becoming smarter. Some have sensors. These sensors help monitor the cutting process. They can adjust the tool’s speed. This makes the tool more efficient. 3D printing is also changing tool making. It allows for custom tools. These tools fit special needs. Innovations help make tools more reliable. They also make them more affordable.

Maintenance And Care Of Turning Tools

Always keep your turning tools clean. Wipe them down after each use. Dirt and debris can cause damage. Inspect your tools regularly. Look for any signs of wear or damage. Replace any worn-out parts immediately. This ensures your tools last longer. A clean tool works better and safer.

Sharp tools work best. Dull tools can be dangerous. Sharpen your tools often. Use a proper sharpening stone. Follow the manufacturer’s guidelines. Keep the original shape of the tool. A well-sharpened tool cuts smoothly. This reduces strain on the lathe. Sharp tools ensure cleaner cuts and better results.

Safety Considerations

Always wear safety glasses to protect your eyes. Gloves can keep your hands safe from sharp edges. Ear protection helps guard against loud noises. A face shield provides extra protection from flying debris. Sturdy footwear keeps your feet safe from heavy objects. A dust mask helps you avoid breathing in harmful particles. A protective apron can shield your body from hot metal and sharp chips.

Keep the work area clean to avoid tripping hazards. Always secure the workpiece properly before starting the lathe. Never leave the lathe running unattended. Check all tools for damage before use. Use the correct speed setting for the material being worked on. Never wear loose clothing or jewelry. Stay focused and avoid distractions while using the lathe.

Case Studies: Precision Projects

Crafting with metal turning tools requires skill. These tools shape metal on a lathe. Experts can make detailed designs. Their work shows true craftsmanship. Using a lathe needs patience and precision. Each project is unique. Every piece tells a story. Skilled hands bring metal to life. The results are amazing and inspiring.

Industry projects teach valuable lessons. Choosing the right tool is crucial. Proper technique ensures success. Practice makes perfect. Mistakes are part of learning. Attention to detail is key. Safety must always come first. Quality materials lead to better results. Collaboration improves outcomes. Always strive for improvement. Learning never stops in this field.

Credit: bigeasymart.com

Future Of Metal Turning Tools

3D printing is changing metal turning tools. Tools are now made faster and cheaper. CNC machines are getting smarter. They can do many tasks with less human help. Artificial Intelligence (AI) helps in making precise cuts. Robots are used for repetitive tasks. This reduces human error. Nanotechnology makes tools last longer. Smaller particles make the tools stronger. Augmented Reality (AR) helps in training workers. Workers can see instructions in real-time.

Automation will take over many tasks. Fewer workers will be needed. Sustainability will become important. Machines will use less energy. Smart sensors will monitor tool health. This will reduce downtime. Customization will be key. Tools will be made to order. Blockchain may track tool use. This ensures quality and trust.

Frequently Asked Questions

Which Tool Is Used For Turning On A Lathe?

A turning tool, also known as a lathe tool, is used for turning on a lathe. It shapes the workpiece.

What Are The Common Metal Lathe Tools?

Common metal lathe tools include cutting tools, boring bars, drill bits, reamers, and parting tools.

What Are The 5 Different Lathe Tools?

The five different lathe tools are turning tools, boring bars, threading tools, parting tools, and facing tools. Each serves a specific function in metalworking and woodworking.

What Are The 5 Main Parts Of A Metal Turning Lathe?

The 5 main parts of a metal turning lathe are the bed, headstock, tailstock, carriage, and the tool post.

Conclusion

Choosing the right metal turning tools for your lathe is crucial. It ensures precision and efficiency in your projects. Invest in high-quality tools to improve your craftsmanship. Regular maintenance will extend their lifespan. Whether a hobbyist or professional, these tools can significantly impact your work.

Happy turning!