Table of Contents

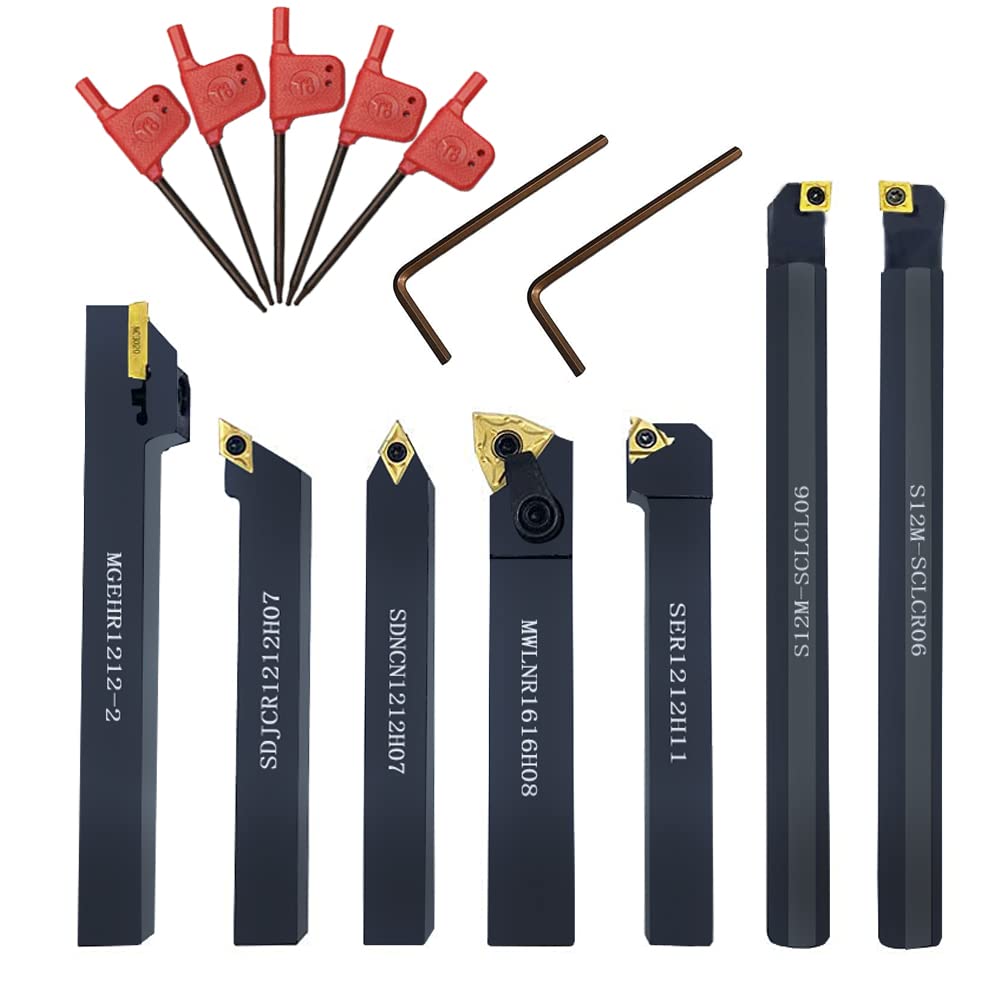

Metal turning tools are essential for shaping and finishing metal workpieces on a lathe. They come in various types for specific tasks.

Metal turning tools are vital in the machining industry, enabling precise shaping and finishing of metal parts. These tools, used on lathes, are designed to cut, shape, and form metals into desired configurations. They come in various types, such as carbide, high-speed steel, and diamond-tipped tools, each suited for specific materials and applications.

Proper selection and use of these tools ensure high-quality finishes and efficient production. Investing in high-quality metal turning tools can significantly enhance the accuracy and efficiency of your metalworking projects. Understanding their types and applications helps in achieving optimal results in metal fabrication.

Introduction To Metal Turning Tools

Metalworking needs tools that are strong and precise. Lathes and cutting tools are common in metal shops. These tools shape and cut metal pieces. The right tools make metalworking easier and faster. Safety is also very important. Always wear protective gear while working with metals.

Precision is key in metal crafting. Accurate measurements make sure parts fit perfectly. Tiny errors can cause big problems. High-quality tools help achieve the best results. Always double-check measurements before cutting. This ensures a smooth crafting process. Skilled hands make a big difference in metalwork.

Types Of Metal Turning Tools

Cutting tools are essential for shaping metal. They come in many types. Common materials include high-speed steel and carbide. High-speed steel is tough. It works well for most metals. Carbide is harder. It lasts longer and is ideal for tough metals.

Specialized tools are used for complex tasks. These tools include boring bars and grooving tools. Boring bars help make precise holes. Grooving tools cut grooves in metal. Using the right tool ensures a perfect finish. Advanced projects often need these specialized tools.

Lathe: The Foundation Of Turning

A metal lathe is a powerful machine. It shapes metal by removing material. Always wear safety goggles. Secure the metal piece tightly. Use the right cutting tool for the job. Start the lathe at a slow speed. Gradually increase the speed as needed. Keep your hands away from moving parts. Never leave the lathe running unattended. Stop the lathe before making adjustments. Regularly check the sharpness of cutting tools. Dull tools can damage your workpiece.

Clean the lathe after each use. Remove all metal shavings. Apply lubricant to moving parts. Lubrication reduces wear and tear. Check the alignment of the lathe regularly. Misalignment can cause poor results. Replace worn-out parts immediately. Keep the lathe covered when not in use. This prevents dust and debris from accumulating. Store cutting tools properly. Sharp tools ensure precise cuts.

Credit: bigeasymart.com

Tool Geometry And Cutting Angles

Metal turning tools have different parts. Each part has a special name. The main parts are the shank, flank, rake face, and cutting edge. The shank is the main body of the tool. The flank is the side of the tool. The rake face helps guide the metal chips away. The cutting edge does the actual cutting.

Correct angles make cutting easier. The rake angle affects chip flow. A positive rake angle makes cutting smoother. The clearance angle prevents the tool from rubbing on the workpiece. The cutting edge angle helps in achieving a good finish. Each angle should be set properly.

Selecting The Right Tool For The Job

Different materials need different tools. Soft metals like aluminum need sharp tools. Hard metals like steel need stronger tools. High-speed steel tools are great for many metals. Carbide tools are better for hard metals. Always match the tool to the metal type.

Tool longevity is very important. Strong tools last longer. Carbide tools often last longer than steel tools. Sharp tools cut better and faster. Dull tools slow down work. Always check your tools often.

Surface Finish And Tool Selection

Choose the right tool to get a smooth surface. A sharp tool helps make clean cuts. Dull tools leave rough marks. The right feed rate is key. Too fast can make a rough surface. Too slow can cause tool wear. Proper lubrication also helps. It reduces friction and heat. This results in a better finish.

High speed can save time but might lower quality. Lower speed often gives a better finish. Balance speed and finish for best results. Use the right cutting tool and speed. It can make a big difference. Test different settings to find the best one. Always check the final product. Make adjustments if needed.

Troubleshooting Common Issues

Metal turning tools often face wear and breakage. Always check the tool’s sharpness before using it. Dull tools increase wear and cause breakage. Proper lubrication helps in reducing wear. Avoid using the tool at high speeds for long periods. This can overheat and weaken the tool. Regular maintenance increases the lifespan of the tool. Inspect the tool after each use. Replace it if there are any signs of damage. Using the right tool for the job is important. Different materials need different tools.

Inaccuracies can ruin a project. Align the tool correctly before starting. Misalignment causes uneven cuts. Check the machine settings for proper speed and feed rate. The workpiece must be secure in the lathe. Loose workpieces move during turning. This causes inaccuracies. Use a steady rest for long workpieces. It keeps them stable. Measure the workpiece often during turning. This ensures it meets the specifications. Keep the lathe bed clean. Debris can affect accuracy.

Credit: www.amazon.com

Advanced Techniques In Metal Turning

CNC turning has transformed metalworking. It allows for precise control and accuracy. This technique uses computer software to guide tools. The process reduces errors significantly. Complex designs are now easier to create. CNC turning machines can work continuously. This increases productivity and reduces downtime.

Complex shapes can be created with metal turning. Special tools and techniques make this possible. Multi-axis machines allow for intricate designs. These machines can handle difficult materials. The result is high-quality parts with precise dimensions. Metal turning is essential for industries like aerospace and automotive.

Safety Considerations And Best Practices

Wear safety goggles to protect your eyes. Always use ear protection to guard against loud noises. Gloves are important to protect your hands. Make sure to wear a dust mask to avoid inhaling metal particles. Sturdy shoes will keep your feet safe from falling objects. Long sleeves and pants are necessary to protect your skin.

Keep your workspace clean and organized. Ensure good lighting to see your work clearly. Use clamps to secure your materials. Make sure all tools are in good condition. Always have a fire extinguisher nearby. Keep first aid kits within reach for emergencies.

Credit: www.pinterest.com

The Future Of Metal Turning Tools

New technologies are changing metalworking. CNC machines are now more advanced. Automation is making the process faster. 3D printing is also being used for metal parts. These tools are more precise. They save time and reduce waste. Smart sensors track performance in real-time. AI helps in making better decisions. Robotics assist in handling heavy materials. These innovations are revolutionizing the industry.

Machinists need to learn new skills. They must understand CNC programming. Knowledge of automation is essential. Software skills are becoming important. Problem-solving abilities are crucial. They need to work with robots and AI. Learning about smart sensors is helpful. Adaptability is key for modern machinists. Continuous learning keeps them updated.

Frequently Asked Questions

What Is The Best Steel For Turning Tools?

High-speed steel (HSS) is the best choice for turning tools. It offers durability, heat resistance, and sharpness retention.

What Are The Common Metal Lathe Tools?

Common metal lathe tools include cutting tools, boring bars, thread cutters, parting tools, and center drills.

What Machine Is Used To Turn Metal?

A lathe machine is used to turn metal. It rotates the metal while cutting tools shape it precisely.

Can A Metal Lathe Be Used For Woodturning?

Yes, a metal lathe can be used for woodturning. Ensure you use proper tools and take necessary safety precautions.

Conclusion

Mastering metal turning tools can significantly boost your productivity and craftsmanship. Invest in quality tools for better results. Stay updated with the latest advancements to maintain a competitive edge. Remember, the right tools are crucial for achieving precision and efficiency in your projects.

Keep honing your skills and enjoy the art of metalworking.