Table of Contents

Metal turning involves shaping metal on a lathe by removing material using a cutting tool. It is essential for precision machining.

Metal turning is a fundamental machining process used in manufacturing and engineering. This technique involves rotating a metal workpiece while a single-point cutting tool removes material to shape it into the desired form. It is widely used to create cylindrical parts, threads, and various detailed components.

Skilled operators and proper tool selection are crucial for achieving high precision and smooth finishes. Understanding the basics of metal turning can significantly enhance your machining capabilities, leading to better product quality and efficiency. Whether you’re a hobbyist or a professional, mastering metal turning opens up a world of possibilities in metalworking.

Credit: m.youtube.com

The Art Of Metal Turning

Metal turning is a process that shapes metal. It uses a lathe machine. The metal piece rotates around a fixed point. A cutting tool is applied to the metal. This tool carves out the desired shape. Precision is very important in metal turning. Skilled workers use many different techniques. They create parts for machines, vehicles, and even art.

Ancient civilizations used basic turning methods. Egyptians used a hand-powered lathe. In the Middle Ages, foot-powered lathes were common. The Industrial Revolution brought major changes. Steam power improved lathe machines. Modern lathes use electric power and computer controls. Technology has made turning faster and more accurate. Today, CNC lathes are widely used. They make complex shapes with high precision.

Credit: turnedwoodenbowls.co.uk

Essential Tools For Metal Turning

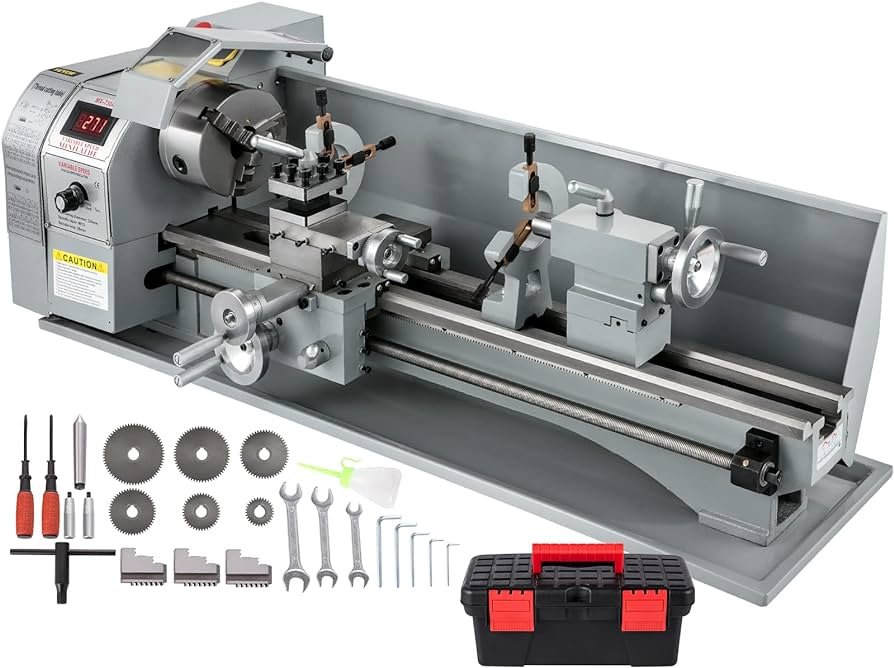

A lathe is the main tool for metal turning. Choose a lathe with a strong motor. This helps in handling tough metals. Ensure the lathe has a solid bed. This keeps the work stable. Variable speed control is useful. It allows for precise turning. Look for a lathe with good safety features. This includes emergency stops and guards.

Cutting tools are vital in metal turning. High-speed steel (HSS) tools are common. They are good for most metals. Carbide tools are tougher. They last longer and cut harder metals. Keep your tools sharp. This gives a clean cut. Use coolant while cutting. This reduces heat and extends tool life. Always choose the right tool for the material. This ensures better results.

Setting Up Your Workspace

Start by clearing your workspace of clutter. Arrange your tools in an easy-to-reach manner. Use bins and shelves to store small parts. A clean workspace helps you work faster and safer. Ensure your workbench is sturdy. Proper lighting is important. It helps you see your work clearly. Use a bright lamp overhead. Keep your workspace well-ventilated. Fresh air is good for your health.

Wear safety glasses to protect your eyes. Gloves can shield your hands from sharp edges. Ear protection is important if the noise is loud. Use a dust mask to avoid inhaling metal particles. Always wear sturdy shoes in the workspace. Keep a first aid kit nearby. It’s good to have in case of minor injuries. Ensure your tools are in good condition. Sharp tools are safer and more effective.

Preparing For Precision

Selecting the right material is very important. Different metals have different properties. Soft metals are easier to turn. Hard metals need special tools. Clean the metal before starting. Remove any dirt or oil. This helps in getting a smooth finish. Cut the metal to the right size. This saves time during turning. Secure the metal properly in the lathe. This prevents accidents. Always wear safety gear.

Use a good quality measuring tool. Measure twice, cut once. This saves material and time. Make small cuts. This helps in getting accurate dimensions. Check the measurements often. This ensures precision. Use a sharp tool for better results. Keep the lathe clean and well-maintained. This ensures smooth operation. Always focus on the work. Avoid distractions to prevent errors.

Techniques For Metal Turning

Metal turning starts with basic operations. Facing removes material from the end. Turning reduces the diameter. Parting cuts a piece off. Boring enlarges a hole. Drilling makes new holes. These steps create the shape you need.

Advanced strategies give better results. Threading adds screw-like patterns. Knurling creates textured surfaces. Grooving makes narrow cuts. Taper turning changes the diameter gradually. These methods require skill and practice.

Troubleshooting Common Issues

Surface finish issues often come from tool wear. Use a sharp tool to get a smooth finish. Check if the tool is aligned correctly. Misalignment can cause rough surfaces. The speed of the machine also matters. Too high or too low speed can affect the finish. Coolant can help too. It keeps the tool and metal cool. This can improve the surface finish.

Tools wear out over time. Regular maintenance is necessary. Check the tool for cracks and chips. Replace worn-out tools promptly. Lubricate moving parts to reduce friction. This extends the tool’s life. Clean the tool after each use. This prevents buildup of metal shavings. Proper storage is also important. Keep tools in a dry, safe place.

Enhancing Turning Efficiency

Speeds and feeds are crucial for turning efficiency. Use the right speed for the material. This reduces tool wear. Set feed rates to prevent tool damage. Always check manufacturer guidelines. Use a speed calculator for accuracy. Adjust speeds based on material hardness. Regularly inspect and maintain tools. Keep cutting edges sharp.

Automated processes can boost efficiency. Use CNC machines for precision. These machines save time. Program them for repetitive tasks. Automation reduces human error. It also ensures consistent quality. Regularly update software. Train staff to use automation tools. This improves productivity.

Credit: elemetgroup.com

Projects To Hone Your Skills

Start with a simple cylinder. This helps you learn basic techniques. Try making a small cup or bowl next. These projects are easy and fun. Experiment with different metals. Aluminum is a good choice for beginners. It is soft and easy to turn. Brass is also good but a bit harder. Practice makes you better.

Try making a threaded bolt. This project needs precision. Gear wheels are another complex project. These need careful measurements. Make a metal chess piece for a real challenge. Use stainless steel for advanced projects. It is tough and durable. Titanium is also a great choice. It is strong and lightweight.

Learning From The Masters

Expert turners have years of practice. They share tips and tricks. Watching their videos can help a lot. John, a master turner, suggests using sharp tools. He says it gives a better finish. Sara, another expert, always wears safety gear. She advises never skipping safety steps.

Tom likes to plan each project. He sketches his designs first. This helps him visualize the final product. Emma focuses on precision. She measures twice and cuts once. These experts teach us valuable lessons.

Books on metal turning are great resources. They provide detailed instructions. Online courses offer interactive lessons. They often include quizzes and videos.

Forums and communities can be very helpful. Members share their experiences and answer questions. YouTube channels also offer tutorials. Some channels have step-by-step guides.

Frequently Asked Questions

How Do You Turn Metal?

To turn metal, use a lathe. Secure the metal, select the appropriate cutting tool, and operate the lathe to shape it. This process involves rotating the metal and applying the tool to achieve the desired form. Always follow safety protocols.

What Machine Is Used To Turn Metal?

A lathe machine is used to turn metal. It shapes, cuts, and drills metal parts with precision.

What Direction Does A Metal Lathe Turn?

A metal lathe typically turns in a clockwise direction when viewed from the tailstock end. This ensures efficient cutting.

Can You Turn Metal On A Lathe?

Yes, you can turn metal on a lathe. Lathes are used for shaping metal by rotating it against cutting tools.

Conclusion

Mastering metal turning can elevate your craftsmanship and project outcomes. Practice regularly to improve your skills. Always prioritize safety and use proper tools. Understanding these techniques opens doors to more advanced projects. Keep learning and refining your expertise in metal turning.

Your efforts will yield impressive and precise results.