Table of Contents

Metal turning epoxy is a durable adhesive used to bond metal surfaces. It provides a strong, resilient bond ideal for various applications.

Metal turning epoxy has become a vital component in many industrial and DIY projects. This adhesive creates a robust bond capable of withstanding intense stress and temperature variations. It offers exceptional resistance to chemicals and moisture, making it suitable for harsh environments.

The epoxy is easy to apply and cures quickly, ensuring efficient project completion. Its versatility allows for use in automotive repairs, machinery, and even artistic metalwork. By choosing metal turning epoxy, you gain a reliable solution for bonding and repairing metal surfaces, ensuring long-lasting durability and performance in your projects.

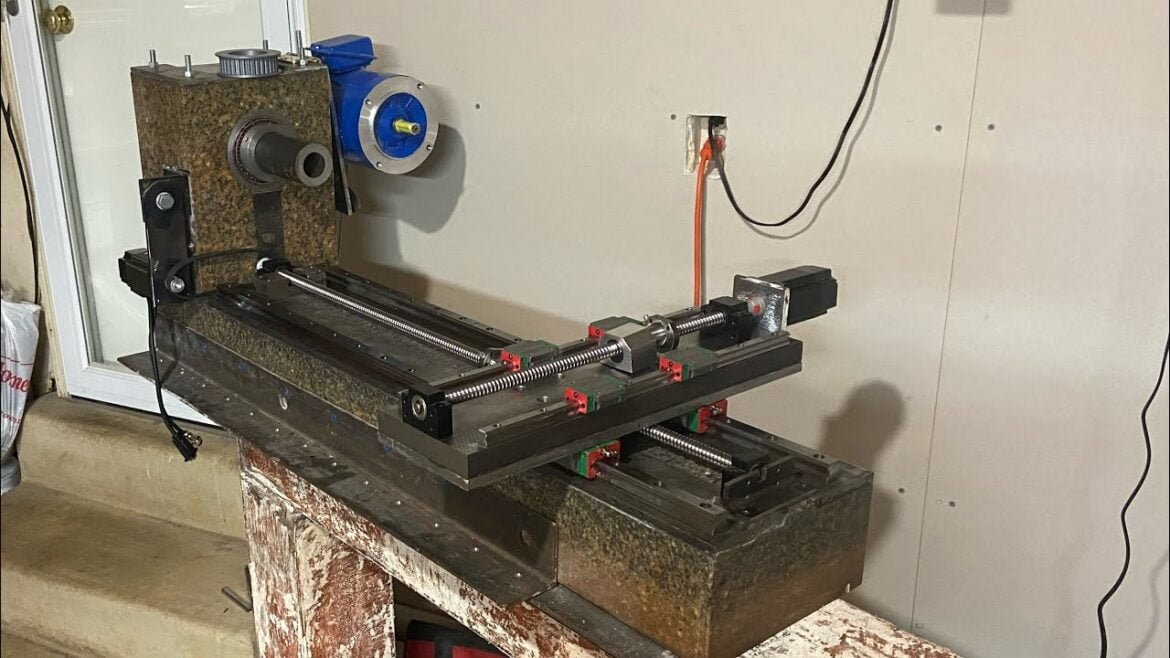

Credit: forum.linuxcnc.org

Introduction To Metal Turning Epoxy

Epoxy is becoming popular in metalworking. It bonds metals very well. People use it to fix broken parts. Epoxy creates a strong and durable bond. It is also resistant to heat and chemicals. This makes it perfect for tough jobs.

Craftsmen and hobbyists love epoxy. It is easy to use. Epoxy can be mixed quickly. It does not need special tools. It is also very versatile. You can use it on many materials. Epoxy is also very affordable. This makes it a great choice for small projects.

Key Properties Of Metal Turning Epoxy

Metal turning epoxy has excellent adhesion to various metals. It forms a strong bond that lasts long. This epoxy is highly durable and resists wear and tear. It can withstand heavy loads without breaking down. This makes it ideal for industrial applications.

This epoxy can resist high temperatures. It does not lose strength when exposed to heat. It also resists chemical attacks. Common chemicals do not affect it. This makes it suitable for harsh environments. It ensures safety and reliability in tough conditions.

Comparing Epoxy To Traditional Metalworking Techniques

Traditional metalworking uses tools like lathes and mills. These tools need expert skills. Epoxy can be easier to use. Even beginners can achieve good results with epoxy.

Epoxy sets quickly. This can save time compared to traditional methods. Metalworking tools need constant adjustments. Epoxy offers more precision without complex machinery.

Applications In Various Industries

Metal turning epoxy finds applications in various industries, providing durable and precise solutions for machinery parts. This versatile material enhances performance and extends the lifespan of equipment.

Automotive And Aerospace

Metal turning epoxy is used in car and plane parts. It makes them strong and durable. Many parts, like engine components, benefit from this epoxy. It helps parts resist heat and stress. This makes vehicles safer and more reliable.

Jewelry And Art

Artists love metal turning epoxy for making beautiful jewelry. It helps create unique designs and fine details. Many artists also use it in sculptures. The epoxy gives a shiny finish and protects the art from damage. It is both a tool and a protective layer.

Step-by-step Guide To Using Metal Turning Epoxy

Gather all necessary materials. You need metal pieces, epoxy resin, gloves, and safety glasses. Clean the metal pieces. Remove any dirt, rust, or oil. Use sandpaper to smooth the surfaces. This helps the epoxy stick better.

Measure the epoxy resin and hardener. Follow the instructions on the package. Mix them together in a clean container. Stir slowly to avoid bubbles. Use a wooden stick or spatula.

Apply the mixed epoxy to the metal surfaces. Use a brush or applicator. Spread it evenly. Make sure all areas are covered. Press the metal pieces together. Hold them in place until the epoxy sets.

Let the epoxy cure for the recommended time. Check the instructions for curing time. Do not disturb the pieces while curing. Once cured, the bond will be strong and durable.

Credit: m.youtube.com

Design Possibilities With Epoxy

Epoxy gives you a lot of creative freedom. You can use it in many ways. It can be colored or clear. This lets you make unique designs. You can also add textures. These can be smooth or rough. Mixing in different materials is easy. You can use glitter, sand, or even small stones. This makes each piece special.

Combining metals with epoxy creates stunning pieces. You can merge metal and epoxy to make art. This mix is both strong and beautiful. Metals like copper and steel work well. They add a modern touch. Epoxy bonds well with metal. This makes the final product very durable. You can use these pieces as jewelry, furniture, or decor.

Tips And Tricks For Mastering Epoxy Metal Turning

Always clean the metal well before starting. This helps the epoxy stick better. Use gloves to keep your hands clean. Mix the epoxy slowly to avoid bubbles. Never use too much epoxy at once. It can cause a mess. Let the epoxy dry completely before touching it. This keeps your project smooth and shiny.

Try adding colors to your epoxy for a cool look. Use a heat gun to remove bubbles from the epoxy. Practice turning the metal slowly for better control. Experiment with different tools for unique designs. Keep your workspace clean and organized. This helps in making fewer mistakes.

Safety Considerations When Working With Epoxy

Always work in a well-ventilated area. Open windows and use fans to keep air moving. This helps to reduce inhaling harmful fumes. Wear Personal Protective Equipment (PPE) like gloves and safety goggles. Gloves protect your skin from direct contact. Goggles shield your eyes from splashes and dust. A face mask can also help to filter out harmful particles. This makes your work environment safer.

Handle epoxy with care. Use tools and not your hands. Read the labels on the products. Follow instructions for mixing and applying. Dispose of leftover epoxy properly. Do not pour it down the sink. Use designated disposal methods. Check local regulations for proper disposal. This keeps the environment clean and safe.

Future Trends In Epoxy And Metalworking

Exciting new technologies are emerging in epoxy and metalworking. 3D printing with epoxy is becoming popular. Smart materials that adapt to conditions are being developed. Nanotechnology is improving the strength of epoxy. Robotics are making metalworking safer and faster. AI helps in designing better tools and methods.

Sustainability is a big focus now. Bio-based epoxies are being created from natural materials. These are better for the environment. Recyclable epoxies are also being developed. This reduces waste. Energy-efficient processes are being used in metalworking. This saves resources and cuts down on emissions. Eco-friendly solutions are the future.

Credit: www.amazon.com

Frequently Asked Questions

What Is The Best Epoxy Resin For Turning?

The best epoxy resin for turning is Alumilite Clear Cast. It offers excellent clarity and durability. It’s ideal for woodworking projects, ensuring a smooth, high-gloss finish.

Can You Turn Epoxy On A Lathe?

Yes, you can turn epoxy on a lathe. Use sharp tools and work at slow speeds for best results.

Can Epoxy Be Used On Metal?

Yes, epoxy can be used on metal. It provides strong adhesion, durability, and resistance to corrosion. Ideal for repairs and coatings.

What Does Epoxy Not Bond To?

Epoxy does not bond to polyethylene, polypropylene, Teflon, silicone, and some plastics. It also struggles with oily or greasy surfaces.

Conclusion

Mastering metal turning epoxy opens up endless creative possibilities. This versatile material ensures durable and beautiful finishes. Whether for DIY projects or professional work, understanding its application can transform your results. Dive into the world of metal turning epoxy and see your projects shine.

Embrace its potential and elevate your craftsmanship.