Table of Contents

Metal lathes can be used for wood turning with proper adjustments and tools. They offer precision and versatility in crafting wood pieces.

Metal lathes, originally designed for shaping metals, are adaptable for wood turning with certain modifications. By using appropriate cutting tools and adjusting the speed settings, these machines can handle the softer material of wood effectively. This approach is beneficial for woodworkers seeking high precision and intricate designs.

Metal lathes provide stable platforms and consistent speed control, making them ideal for detailed wood projects. Ensuring the lathe is properly set up and maintained is crucial for safety and optimal performance. Using a metal lathe for wood turning opens up new possibilities for creative and precise woodworking projects.

Introduction To Metal Lathe Wood Turning

Metal lathe wood turning is an exciting craft. It blends the precision of metalworking with the artistry of wood turning. This technique opens up endless possibilities for creating unique wooden pieces.

The Fusion Of Metal And Wood

Combining metal lathes with woodturning tools may seem odd. Yet, this fusion brings remarkable results. Metal lathes offer high precision. They allow for intricate designs on wood. This blend of metal and wood highlights the best of both worlds.

Woodturners can now achieve tighter tolerances. They can also create detailed patterns. The metal lathe’s stability reduces vibrations. It helps in achieving smooth finishes on wood.

Historical Significance

Metal lathes have a rich history. They date back to the Industrial Revolution. Initially, they were used to machine metal parts. Woodworkers soon realized the potential for wood turning.

Early woodturners adapted metal lathes. They found new ways to shape and design wood. This led to the evolution of specialized tools and techniques.

| Era | Significance |

|---|---|

| 18th Century | Metal lathes primarily for metalwork |

| 19th Century | Woodworkers start using metal lathes |

| 20th Century | Refinement of tools and techniques |

Today, metal lathe wood turning is a respected craft. It combines the best of both metalworking and woodworking traditions.

Credit: turnedwoodenbowls.co.uk

Essential Tools And Materials

Metal lathe wood turning requires specific tools and materials. The right equipment ensures precision and quality in your projects. This section covers the essential tools and materials needed for successful metal lathe wood turning.

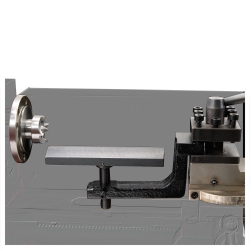

Choosing The Right Lathe

Choosing the right lathe is crucial. A good lathe provides stability and precision. Here are some key features to consider:

- Bed length: Determines the maximum length of the workpiece.

- Swing over bed: The maximum diameter of the workpiece.

- Motor power: Affects the machine’s ability to handle tougher materials.

- Speed control: Variable speeds allow for different types of turning.

- Tool rest: Supports the cutting tools during the turning process.

Below is a table summarizing these features:

| Feature | Description |

|---|---|

| Bed length | Maximum length of the workpiece |

| Swing over bed | Maximum diameter of the workpiece |

| Motor power | Affects ability to handle tougher materials |

| Speed control | Allows for different types of turning |

| Tool rest | Supports cutting tools during turning |

Selecting Wood And Metal

Selecting wood and metal for your projects is important. Different materials offer different properties and finishes.

Wood types:

- Hardwood: Durable and fine-grained. Examples: oak, maple.

- Softwood: Easier to turn but less durable. Examples: pine, cedar.

Metal types:

- Steel: Strong and versatile.

- Aluminum: Lightweight and easy to machine.

- Brass: Corrosion-resistant and attractive.

Using the right materials ensures your projects are both beautiful and functional. Always choose materials based on the project’s needs and your skill level.

Setting Up Your Workspace

Setting up your workspace is crucial for successful metal lathe wood turning. A well-organized and safe area ensures precision and efficiency. Below, we will discuss important steps to create the perfect workspace.

Safety Measures

Safety must come first in any workshop. Follow these key safety measures to protect yourself:

- Wear safety goggles to protect your eyes from debris.

- Use ear protection to prevent hearing damage from loud machinery.

- Keep a fire extinguisher nearby for emergencies.

- Ensure good ventilation to avoid inhaling dust and fumes.

- Wear gloves that fit well, but avoid loose clothing.

Organizing Tools And Materials

Organization is key to an efficient workspace. Keep your tools and materials well-arranged:

| Category | Tools | Materials |

|---|---|---|

| Lathe Tools | Chisels, gouges, parting tools | Metal blanks, wood pieces |

| Measuring Tools | Calipers, micrometers, rulers | Templates, patterns |

| Safety Gear | Goggles, ear protection, gloves | Dust masks, aprons |

Use labeled drawers or bins to store your tools. This helps you find them quickly. Keep frequently used items within easy reach. Clean your workspace regularly to prevent clutter.

Credit: littlemachineshop.com

Basic Techniques In Metal Lathe Wood Turning

Metal lathe wood turning combines the precision of metalworking with the artistry of woodworking. This unique craft allows for the creation of intricate designs and shapes. Below, we explore the basic techniques that can help you master this skill.

Preparing The Wood And Metal

Before starting, gather the necessary materials. Ensure the wood and metal are suitable for turning. Select a piece of wood that is free of cracks and knots. Choose metal that is compatible with your lathe.

Secure the wood in the lathe’s chuck. Ensure it is centered and stable. For metal, use appropriate cutting tools to prepare the metal piece. Clean both materials to remove any debris or oils.

The Art Of Shaping

Shaping is a crucial step in metal lathe wood turning. Use sharp tools for precise cuts. Start with a roughing gouge to remove large sections of wood. Shape the wood into a basic form.

Switch to finer tools for detailed work. Skew chisels and parting tools create intricate designs. Always move the tools slowly and steadily. Monitor the shape and adjust as needed.

For metal, use carbide-tipped tools. These provide clean and accurate cuts. Follow similar steps as with wood, but apply more pressure.

Practice different techniques to improve your skills. Each piece will enhance your understanding and control.

| Tool | Use |

|---|---|

| Roughing Gouge | Initial shaping |

| Skew Chisel | Detailed work |

| Parting Tool | Creating grooves |

| Carbide-Tipped Tool | Metal shaping |

Advanced Turning Techniques

Mastering advanced turning techniques in metal lathe wood turning can elevate your projects. You can create stunning pieces with intricate details and unique combinations. This section explores two key techniques: intricate designs and patterns, and combining different materials.

Intricate Designs And Patterns

Creating intricate designs and patterns requires precision and skill. Here are some tips to achieve them:

- Use fine-point tools for detailed work.

- Maintain a steady hand for even cuts.

- Work slowly to avoid mistakes.

Consider these popular patterns:

| Pattern Type | Description |

|---|---|

| Spiral | A continuous winding design. |

| Fluting | Grooves carved along the length. |

| Beading | Small, rounded ridges. |

Combining Different Materials

Combining different materials can enhance the visual appeal of your work. Here are some ideas:

- Mix wood with metal for a modern look.

- Use resin inlays for colorful accents.

- Incorporate stone for a natural touch.

Each material has unique properties. Understand them before starting your project. Experiment with different combinations to find what works best for you.

Credit: www.youtube.com

Finishing Touches

The finishing touches can make your woodturning project shine. A smooth and polished surface will catch the eye. These steps ensure your project looks professional and complete.

Sanding And Polishing

Sanding is the first step in achieving a smooth finish. Start with a coarse grit sandpaper. Gradually move to finer grits. Sand the entire surface evenly. Use a sanding block for flat areas. For curved surfaces, use flexible sanding pads.

After sanding, the surface will feel smooth. But it still needs polishing. Use a polishing compound for this. Apply the compound with a soft cloth. Buff the surface until it shines. Repeat the process if needed.

| Step | Action | Tools |

|---|---|---|

| 1 | Sanding (coarse grit) | Coarse grit sandpaper, sanding block |

| 2 | Sanding (fine grit) | Fine grit sandpaper, sanding pads |

| 3 | Polishing | Polishing compound, soft cloth |

Applying Finishes

Applying finishes adds a protective layer to your project. It enhances the wood’s natural beauty. There are various types of finishes:

- Oil Finishes

- Wax Finishes

- Polyurethane

- Shellac

Each type of finish has its benefits. Oil finishes penetrate the wood. They provide a natural look. Wax finishes give a soft sheen. They are easy to apply and maintain.

Polyurethane is durable and provides excellent protection. It is ideal for items that will be handled often. Shellac offers a high-gloss finish. It dries quickly and is easy to apply.

- Choose the right finish for your project.

- Apply the finish with a clean brush or cloth.

- Let it dry completely.

- Apply additional coats if needed.

Each coat of finish adds depth and protection. Your project will look stunning and last longer.

Showcasing Your Work

Displaying your metal lathe wood turning creations can be thrilling. You want others to see your skill and artistry. Showcasing your pieces well helps you reach a wider audience. Here are some methods to ensure your work stands out.

Photographing Your Pieces

High-quality photos of your work are essential. Clear, bright images highlight details. Use natural light when possible. It minimizes shadows and enhances colors.

Consider using a lightbox. It helps create a consistent and professional look. Keep the background simple and neutral. This ensures your piece is the main focus.

- Use a tripod for steady shots.

- Capture multiple angles.

- Show close-ups of intricate details.

Exhibiting At Shows And Galleries

Exhibiting your work in shows and galleries can boost your visibility. It allows you to connect with art lovers and collectors.

Research local art shows and galleries. Find ones that align with your style. Apply for exhibitions and prepare a strong portfolio. Include your best pieces and high-quality photographs.

| Task | Details |

|---|---|

| Research | Find relevant shows and galleries. |

| Apply | Submit your portfolio and application. |

| Prepare | Select and prepare your best pieces. |

Engage with visitors at the shows. Share the story behind each piece. This personal touch can make a big difference.

Challenges And Solutions In Wood Turning

Metal lathe wood turning can be challenging. Issues arise that can frustrate beginners and experts alike. Understanding these challenges and their solutions helps improve skills and results.

Common Issues

Several common issues can occur in wood turning. These include:

- Chatter: Vibration that leaves rough surfaces.

- Tear-Out: Wood fibers tear instead of cut cleanly.

- Tool Dulling: Tools lose sharpness quickly.

- Wood Cracking: Wood splits during or after turning.

Troubleshooting Tips

Addressing these issues requires specific solutions. Here are some helpful troubleshooting tips:

- Chatter: Use a steady rest. Ensure the tool is sharp.

- Tear-Out: Use a sharper tool. Turn with the grain.

- Tool Dulling: Sharpen tools regularly. Use quality tool steel.

- Wood Cracking: Use properly dried wood. Apply finishing oils.

| Issue | Solution |

|---|---|

| Chatter | Use a steady rest, sharpen the tool. |

| Tear-Out | Use sharper tools, turn with the grain. |

| Tool Dulling | Sharpen tools regularly, use quality steel. |

| Wood Cracking | Use dried wood, apply finishing oils. |

Frequently Asked Questions

Can You Use A Metal Lathe For Wood Turning?

Yes, you can use a metal lathe for wood turning. Ensure to use appropriate tools and adjust speeds accordingly.

Is A Metal Lathe The Same As A Wood Lathe?

No, a metal lathe and a wood lathe are not the same. Metal lathes handle harder materials and have higher precision. Wood lathes are designed for softer materials and offer less precision. Both have distinct features and uses.

Can You Spin Metal On A Wood Lathe?

No, you can’t spin metal on a wood lathe. Wood lathes lack the strength and precision needed for metalworking.

Why Are Metal Lathes So Expensive?

Metal lathes are expensive due to high-quality materials, precision engineering, and advanced technology. They ensure durability and accuracy in machining tasks.

Conclusion

Mastering metal lathe wood turning can elevate your woodworking projects. It offers precision, versatility, and creative possibilities. Whether you’re a beginner or expert, this skill enhances craftsmanship. Embrace the techniques and tools discussed for impressive results. Start turning wood on a metal lathe and watch your projects transform.

Happy turning!