Table of Contents

The best metals for lathe turning include aluminum, brass, and mild steel. These metals offer excellent machinability and precision.

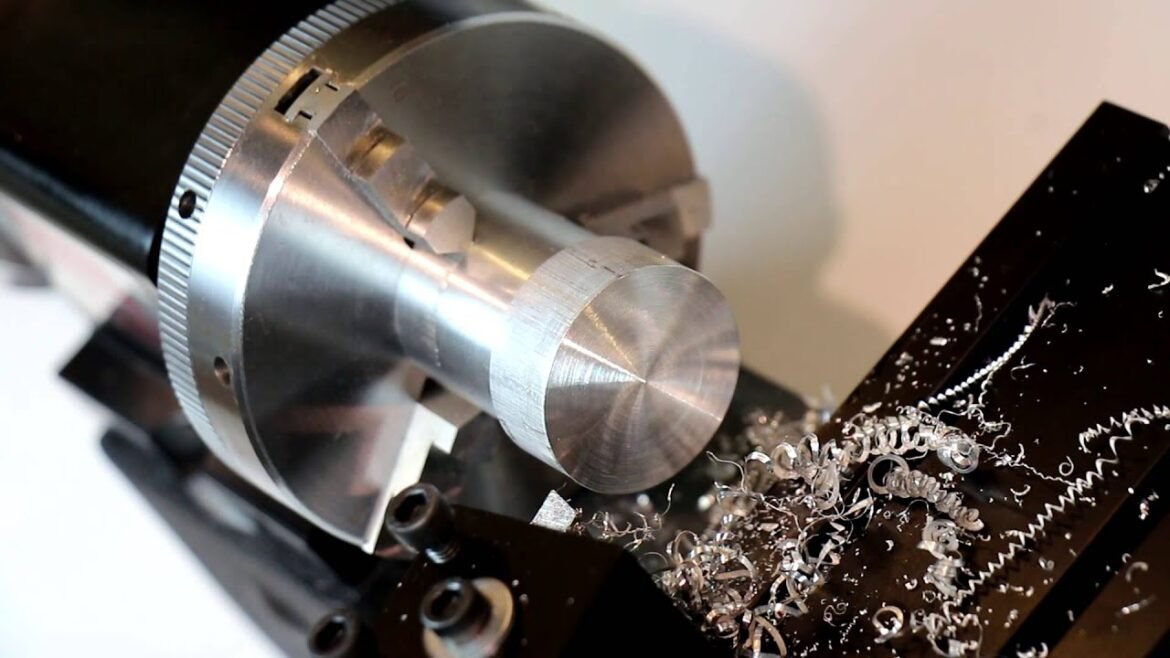

Lathe turning is a crucial process in metalworking, involving the use of a cutting tool to remove material from a rotating workpiece. Choosing the right metal for lathe turning is essential for achieving high-quality results. Aluminum is popular due to its lightweight and easy machinability.

Brass offers good corrosion resistance and is easy to turn, making it ideal for decorative items. Mild steel, known for its strength and versatility, is commonly used in various applications. By selecting the appropriate metal, machinists can ensure efficient operations, reduced tool wear, and superior finished products.

Credit: elemetgroup.com

Introduction To Lathe Turning

The lathe is a key tool in metalworking. It shapes metal with high precision. Craftsmen use it to create intricate designs. The lathe rotates the metal piece. This allows for smooth cuts and detailed finishing.

Precision is vital in lathe turning. Accurate measurements ensure perfect results. Skilled craftsmen handle the lathe with care. They achieve fine details through careful control. Each turn of the lathe matters. It brings the design to life.

Credit: turnedwoodenbowls.co.uk

Selecting The Right Metal

Different metals have unique properties. Some metals are soft, while others are hard. Steel is strong and hard. Aluminum is light and easy to cut. Brass is soft and has a nice color. Each metal reacts differently to heat. Steel can handle high heat. Aluminum cools quickly. Brass stays cool.

The cost of metal is important. Steel is often cheap. Aluminum costs more but is light. Brass is expensive but looks nice. Choosing the right metal can save money. Think about the project needs. Pick a metal that fits the budget and works well.

Aluminum: Lightweight And Versatile

Aluminum is a popular choice for lathe turning. It is lightweight, which makes it easy to handle. It is also versatile and can be shaped into many forms. Aluminum is less likely to rust, making it a durable option. Machinists enjoy working with aluminum due to its softness. This makes it easier to cut and shape. Aluminum is also recyclable, which helps the environment.

Finishing techniques are important for aluminum projects. Polishing gives aluminum a shiny look. Painting adds color and protection. Anodizing strengthens the surface and adds color. Sandblasting can give a matte finish. Each technique adds value and beauty to the aluminum piece.

Steel: The Sturdy Workhorse

Steel is a popular choice for lathe turning. There are several types of steel. Carbon steel is common and affordable. Alloy steel contains other metals for strength. Stainless steel resists rust and is durable. Each type has unique properties. Choosing the right steel depends on the project.

Heat treatment changes steel properties. It can make steel harder or softer. Annealing makes steel soft and easy to machine. Quenching makes it very hard. Tempering balances hardness and toughness. Machinability depends on the steel type and treatment. Proper treatment ensures the best results.

Brass And Copper: For Intricate Details

Brass and copper are non-ferrous metals. They are easy to machine. These metals do not rust. They are perfect for detailed work. Brass is good for gears and valves. Copper is great for electrical parts. These metals can be cut with precision.

Brass and copper have a shiny look. They polish well. These metals are used for decorative items. They can be given different finishes. Polished brass looks bright and gold-like. Copper can have a smooth or textured finish. These finishes make items look elegant.

Credit: www.reddit.com

Specialty Metals: Titanium And More

Exotic metals like titanium are very strong. They can withstand high temperatures. These metals do not rust easily. They are also very lightweight. This makes them perfect for many uses.

Working with exotic metals needs special tools. These tools must be very hard. They should also be very sharp. The metals can be tough to cut. The tools must also be very precise. It is important to handle these metals carefully. Proper safety gear is needed. This includes gloves and goggles. The workspace must also be clean. This helps to avoid any accidents.

Tools And Techniques For Effective Turning

Cutting tools should be sharp and durable. The best tools are made of high-speed steel or carbide. Inserts are small parts that attach to the cutting tool. They help in cutting metal more effectively. There are different shapes and sizes of inserts. Each insert is used for a specific type of cut. Make sure to choose the right insert for the job. Using the wrong insert can cause poor cuts or tool damage. Regularly check and replace worn inserts.

Speeds and feeds are crucial in lathe turning. Speed refers to how fast the tool moves. Feed is how quickly the material moves towards the tool. Always follow the recommended settings for your material. This helps in getting a smooth finish. Tolerances are the allowable limits in the size of the final product. Precision is key to achieving the desired tolerances. Use measuring tools to check your work frequently.

Safety First: Best Practices In The Workshop

Wear safety goggles to protect your eyes from flying debris. Use ear protection to guard against loud noises. Always wear gloves to protect your hands from sharp edges. Keep a fire extinguisher nearby in case of emergency. Make sure to wear a dust mask to avoid inhaling harmful particles. Steel-toed boots protect your feet from heavy objects. Ensure all clothing is snug to avoid getting caught in machinery.

Clean the lathe after each use to remove metal shavings. Check for loose bolts and tighten them regularly. Apply lubrication to moving parts to ensure smooth operation. Inspect the cutting tools for wear and replace them as needed. Calibrate the machine to ensure it produces accurate work. Keep the work area clean to prevent accidents. Store tools in their designated places to avoid misplacement.

Troubleshooting Common Issues

Tool chatter can ruin your work. Use a sharp tool to reduce chatter. Keep your lathe speed low. Make sure the workpiece is secure. Adjust the tool angle if needed. Use a solid tool holder. Check for loose parts on the lathe.

Material warping happens when metal bends. Cooling the metal slowly helps. Use a steady hand. Clamp the material well. Check the metal for defects. Avoid overheating. Use the right cutting fluid. Monitor your work carefully.

Innovation In Metal Turning

CNC technology has transformed metal turning. Machines now work with greater precision. They complete tasks faster than ever. Automation has reduced human error. These machines can repeat tasks perfectly. This leads to better quality products. More industries now use CNC for their needs. Complex designs are easier to achieve.

New materials are being developed for metal turning. These materials are stronger and more durable. They can withstand higher temperatures. Nanotechnology is being explored. It might lead to even stronger metals. Sustainable practices are also on the rise. This means less waste and more efficient use of resources. Hybrid techniques are becoming popular. They combine traditional and modern methods.

Frequently Asked Questions

What Material Is Used For Lathe Turning?

Lathe turning typically uses materials like steel, aluminum, brass, copper, plastic, and wood. These materials offer durability and versatility.

What Metals Can Be Turned On A Lathe?

A lathe can turn metals like aluminum, brass, copper, steel, stainless steel, and titanium. Each requires specific tools and speeds.

What Steel Is Good For Turning?

For turning, 12L14 steel is excellent due to its machinability. It offers smooth finishes and reduces tool wear.

What Is The Best Metal For Lathe Tools?

The best metal for lathe tools is high-speed steel (HSS). It offers durability and excellent cutting performance.

Conclusion

Choosing the right metal for lathe turning is crucial for precision and durability. By understanding material properties, you can achieve better results. Always consider factors like hardness, machinability, and cost. Proper metal selection ensures efficient and accurate work. Enhance your lathe projects by making informed choices on metal types.