Table of Contents

Lathe turning projects involve shaping materials like wood, metal, or plastic into precise forms. These projects require skill and precision.

Lathe turning is a versatile and essential process in machining and woodworking. It allows artisans and machinists to create intricate designs and functional components. Common projects include crafting furniture legs, custom pens, bowls, and mechanical parts. Lathe turning projects not only enhance technical skills but also foster creativity.

Beginners can start with simple items, gradually moving to complex designs. Safety is paramount, so always wear protective gear. With practice, anyone can master lathe turning and produce professional-quality items. This craft combines artistry with engineering, making it a rewarding hobby or career.

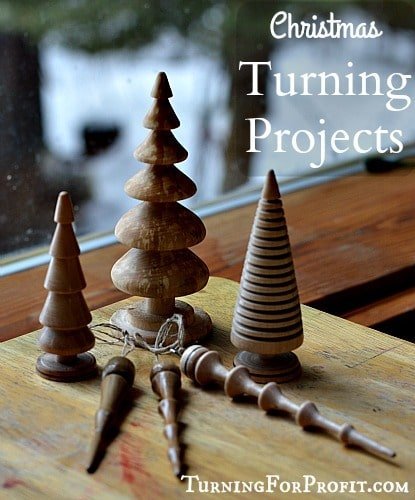

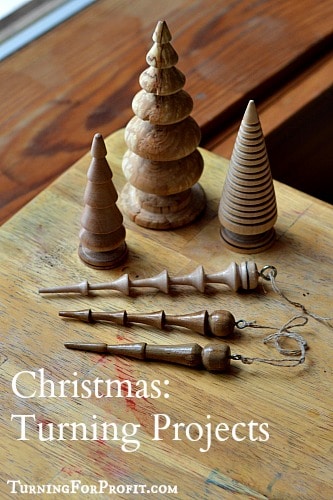

Credit: www.turningforprofit.com

Introduction To Lathe Turning

Lathe turning is an ancient craft. It involves shaping materials like wood or metal. A lathe spins the material while a tool shapes it. This process can create many things. Examples include bowls, pens, and furniture parts. Lathe turning requires skill and patience. It can be very rewarding. Many people enjoy this hobby. It allows for creativity and precision.

The art of shaping materials with a lathe is fascinating. You can make intricate designs. Skilled hands can turn simple blocks into beautiful objects. Practice is key. Start with simple projects. Gradually try more complex ones. Safety is important. Always wear protective gear. Keep your tools sharp. This helps in making clean cuts. Enjoy the process and learn from each project.

Having the right tools is crucial. Here is a list of essential tools for lathe projects:

- Lathe Machine – The main tool for turning.

- Chisels – Used for cutting and shaping.

- Calipers – Measure your work precisely.

- Goggles – Protect your eyes.

- Gloves – Keep your hands safe.

- Sandpaper – Smooth out your projects.

Selecting Your Material

Wood is a great choice for lathe turning. Hardwoods like oak and maple are strong. They are also durable. Softwoods such as pine are easier to work with. They are not as strong as hardwoods. Exotic woods can be very beautiful. They may be harder to find. Each wood type has its own unique grain and color.

Metals are also popular for lathe turning. Aluminum is lightweight and shiny. It is easy to shape. Brass has a gold-like shine. It is also very durable. Steel is the strongest. It is also the most durable. Copper has a reddish color. It is a bit softer than other metals. Each metal has its own special properties. Choose the one that fits your project best.

Safety First

Prioritize safety in lathe turning projects by wearing proper protective gear. Ensure tools are sharp and machines are well-maintained.

Personal Protective Equipment

Wearing safety goggles protects your eyes from flying debris. Gloves shield your hands from sharp edges. Ear protection guards against loud noises. A dust mask prevents inhaling harmful particles. Sturdy footwear keeps your feet safe from heavy objects. Avoid loose clothing to prevent entanglement. Tie back long hair for safety. Keep a first aid kit nearby for emergencies.

Lathe Operation Best Practices

Inspect the lathe before each use for any damage. Secure the workpiece firmly to avoid accidents. Set the correct speed for the material you are working with. Use sharp tools for cleaner cuts and less strain. Keep hands clear of the rotating parts. Always stand to the side of the workpiece when starting the lathe. Stop the lathe before making any adjustments. Clean the workspace regularly to avoid clutter.

Basic Lathe Techniques

First, ensure the lathe is on a stable surface. Next, check all parts for any damage. Secure the workpiece firmly in the chuck. Make sure all safety gear is worn. This includes goggles and gloves. Adjust the tool rest to the correct height. Always keep it close to the workpiece. Turn on the lathe at a low speed. Gradually increase the speed as needed. Keep hands away from the spinning parts.

Facing is a basic method. It smooths the end of the workpiece. Turning reduces the diameter of the workpiece. Parting cuts off a section of the workpiece. Drilling creates holes in the workpiece. Boring enlarges existing holes. Knurling adds texture to the workpiece. Always use sharp tools for best results.

Beginner-friendly Turning Projects

Wooden pens are easy to make. Start with a small piece of wood. Use a lathe to shape it. Sand it smooth. Add a finish to make it shine. Attach the pen parts. Now, you have a beautiful wooden pen. This project teaches basic lathe skills. It also makes a great gift.

Candle holders are perfect for beginners. Choose a piece of wood. Mount it on the lathe. Shape it into a holder. Sand it until smooth. Apply a finish for shine. These holders can be simple or fancy. They make great home decorations. They are also good practice for new turners.

Intermediate Challenges

Classic wooden bowls are a favorite project for intermediate woodworkers. These bowls require precise turning skills. Start with a solid block of wood. Secure it on the lathe and shape the exterior first. Smooth the surface with sandpaper. Hollow out the inside carefully. A sharp tool is essential for clean cuts. Finish the bowl with a food-safe oil. This enhances the wood’s natural beauty.

Custom chess pieces make great gifts or personal collectibles. Each piece has unique shapes and sizes. Turn the base first, then shape the upper part. Use a template for consistency. Sand each piece smoothly. Add details with a small carving tool. Finish with a clear coat for protection. Label each piece clearly for easy identification. This project helps improve precision and attention to detail.

Advanced Artistry On The Lathe

Creating vases on a lathe can be fun. Intricate designs make the project more interesting. Simple shapes are a good start. Moving on to detailed patterns makes the vase special. Try using different wood types. This will add color and texture. Don’t forget to sand and polish your vase. It should shine and be smooth.

Making table legs can be a great project. Elaborate designs add beauty to any table. You can start with simple shapes. Progress to more detailed carvings as you gain skill. Using hardwoods will make the legs strong. Symmetry is important, so make sure each leg matches. Sanding and finishing are key steps. Your table legs will look professional and polished.

Finishing Touches

Use fine-grit sandpaper for a smooth surface. Sand along the grain to avoid scratches. A sanding block helps keep the surface even. For curves, use a flexible sanding sponge. Start with coarse grit and move to finer grits. This removes rough spots and makes the wood smooth. Clean the dust after each sanding step. A damp cloth can help remove fine dust particles.

Test the stain on a scrap piece first. This ensures the color is right. Apply the stain with a brush or cloth. Wipe off excess stain with a clean rag. Let it dry completely before adding varnish. Use a brush to apply varnish in thin, even coats. Sand lightly between coats for a smooth finish. Let each coat dry fully before adding the next. This gives the wood a rich, protective finish.

Showcasing Your Work

Good photos make your projects shine. Use a clean background to highlight your work. Natural light helps to show details better. Avoid shadows and glare. Take pictures from different angles. Close-up shots capture fine details. Use a tripod to keep your camera steady. Edit your photos to enhance colors and clarity. Share your best shots on social media.

Join online forums to share your projects. Engage with other makers and get feedback. Attend local maker fairs to meet others. Share your knowledge and learn new tips. Collaboration can lead to new ideas. Being part of a community is fun and rewarding. You can inspire and be inspired.

Credit: www.pinterest.ca

Maintenance And Care For Your Lathe

Clean the lathe after every use. Remove all chips and debris. Use a soft cloth to wipe down surfaces. Apply machine oil to prevent rust. Check for loose parts or screws. Keep the area around the lathe tidy. This helps to avoid accidents.

Is the lathe making strange noises? Check the bearings for wear. Does the tool not cut well? Sharpen or replace the cutting tool. Is the lathe vibrating? Ensure it’s on a stable surface. Clean the chuck if workpieces slip. Regularly inspect electrical connections for safety. Proper maintenance prevents big problems.

Expanding Your Skillset

Mastering advanced turning techniques can take your projects to the next level. Learning to use different cutting tools can create unique designs. Precision and accuracy are key for advanced projects. Experiment with speed settings to achieve smooth finishes. Combining multiple techniques can result in beautiful and complex pieces.

Enrolling in courses can boost your skills. Many workshops offer hands-on training. Experienced instructors can provide valuable tips and tricks. Online courses are also available for flexible learning. Joining a community can offer support and inspiration. Always seek opportunities to improve and grow.

Credit: www.fouroakscrafts.com

Incorporating Technology

CAD software helps in creating precise designs. It allows for detailed 3D models. These models guide the lathe machine. Errors get reduced using CAD. It ensures high-quality outcomes.

Designs can be easily edited. This saves time and resources. CAD files can be shared and reused. This promotes consistency in projects.

CNC machines are crucial in modern turning. They offer high precision and repeatability. CNC uses computer controls to operate lathes. This reduces manual effort and human error.

CNC machines can handle complex designs. They are efficient and fast. This makes them ideal for large-scale production. The technology enables consistent quality in every piece.

Frequently Asked Questions

What Is The Easiest Wood Turning Project?

A simple wood turning project is making a wooden pen. It’s easy, quick, and perfect for beginners.

Can A Lathe Be Used For Turning?

Yes, a lathe is used for turning. It rotates the workpiece while cutting tools shape it. This process creates cylindrical parts.

What Wood Is Used For Turning Projects?

Popular woods for turning projects include maple, cherry, walnut, and oak. These woods are durable and attractive. Exotic woods like ebony and cocobolo are also favored for their unique patterns. Choose wood based on your project’s requirements and desired finish.

What Can You Turn On A Mini Lathe?

You can turn wood, plastic, and metal on a mini lathe. Create small parts like spindles, bushings, and pens.

Conclusion

Lathe turning projects offer endless opportunities for creativity and skill development. They range from simple to complex designs. Engaging in these projects enhances craftsmanship and provides a sense of accomplishment. Start your next lathe turning project today and discover the joy of creating with your own hands.