Table of Contents

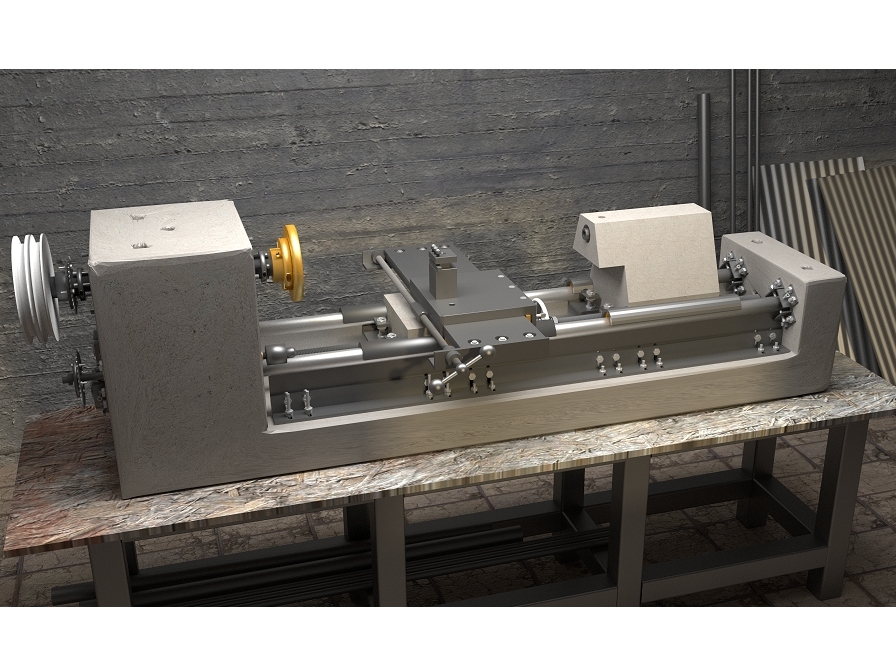

To build a metal turning lathe, gather all necessary materials and tools. Then, follow precise construction steps for assembly.

Building a metal turning lathe requires meticulous planning and execution. A lathe is a versatile machine essential for metalworking, enabling the creation of intricate parts and components. Before starting, gather materials such as metal stock, bearings, a motor, and various fasteners.

Essential tools include a welder, drill press, and cutting tools. Careful measurement and alignment are crucial to ensure accuracy and functionality. Constructing the base and headstock, installing the motor, and aligning the tailstock are key steps. With patience and precision, you can build a reliable metal turning lathe suitable for various projects.

Credit: m.youtube.com

Introduction To Metal Turning Lathes

Metal turning lathes are important tools in metalworking. They spin metal pieces while cutting. This shapes the metal with precision. Lathes help create parts for machines, cars, and many other items.

The Role Of Lathes In Metalworking

Lathes can cut, sand, and drill metal. They are used by machinists and hobbyists. Metalworking lathes can create complex shapes. They are crucial for making tools and parts.

Diy Vs. Commercial Lathe

Building a DIY lathe can be fun. It is cheaper and a learning experience. But it may not be as precise. Commercial lathes are expensive. They are designed for accuracy and durability. Choosing between DIY and commercial depends on your needs.

Credit: www.winburn.com

Essential Tools And Materials

Gather essential tools and materials for building a metal turning lathe, including a lathe bed, headstock, tailstock, and cutting tools. Ensure precision with measuring instruments like calipers and micrometers for accurate machining.

Gathering Your Supplies

Gathering the right supplies is very important. Start with basic tools like a hammer, wrench, and screwdriver. You will also need a metal saw and a drill. Don’t forget protective gear like gloves and safety glasses. Have a sturdy workbench ready. Make sure all tools are in good condition. This will help avoid any accidents. Good quality tools will make the job easier.

Choosing The Right Metal

Choose a metal that suits your project. Aluminum is lightweight and easy to work with. Steel is stronger and more durable. Brass is good for decorative parts. Each metal has different properties. Think about the final product. This will help you decide which metal to use. Make sure the metal is free of rust and defects. Clean metal works best.

Designing Your Lathe

Good blueprints are very important. They help you build the lathe correctly. Draw the lathe parts clearly. Show all measurements on the plans. Use simple symbols to avoid confusion.

Customization is key. Change the design to fit your needs. Make it bigger for larger projects. Add extra features if needed. Always double-check your plans. Mistakes can be costly.

Each project is unique. Customize the lathe to match your project. Use different materials for different tasks. Some metals are harder to cut. Choose the right tools and accessories.

Customization makes your lathe versatile. Change the speed for different jobs. Adjust the tool rest for better control. Always keep safety in mind. Wear protective gear.

Creating The Lathe Bed

Use a strong metal to create the lathe bed. Cut the metal to the right length. Make sure the edges are smooth. Shape the metal carefully. This will help the lathe work well. Measure twice before cutting. This ensures the bed is the correct size. Use a metal file to smooth rough edges. This will make the bed safe to handle.

The lathe bed must be stable. Place the bed on a flat surface. Use a level to check for balance. Add support if needed. This prevents shaking during use. Tighten all bolts and screws. This keeps the bed firm. Check for any loose parts regularly. Stability is key for precise work. A stable bed helps in accurate metal turning. Precision is crucial for a good finish.

Assembling The Headstock And Tailstock

Start by gathering all the tools. Clean the bearings to remove any dirt. Place the bearings in the correct slots. Make sure they fit snugly. Tighten the screws to hold the bearings in place. Double-check that the bearings are secure.

Place the spindle in the headstock. Align it with the bearings. Use a ruler to check the alignment. Adjust the spindle if needed. Ensure it is perfectly straight. Tighten the bolts to secure the spindle. Spin the spindle to test the alignment.

Credit: makezine.com

Constructing The Carriage And Toolpost

The carriage moves the cutting tool. It must be strong and precise. Use steel for durability. Attach it to the bed with bolts. Ensure it slides smoothly. Add ball bearings for easy movement. The leadscrew drives the carriage. It must be aligned well. A misaligned leadscrew can cause errors. Test the carriage frequently.

The toolpost holds the cutting tool. It should be adjustable and stable. Use cast iron for the toolpost. Attach it to the carriage with bolts. Ensure it can rotate. This allows for different cutting angles. Check the alignment often. A misaligned toolpost can damage the workpiece. Install a locking mechanism for stability.

Electrical Components And Motorization

Creating a metal turning lathe involves assembling various electrical components and motorization techniques. Mastering these steps ensures precision and efficiency in your metalworking projects.

Selecting A Motor

Choose a motor with enough power. A 1 to 2 HP motor is usually good. Make sure it fits your lathe size. Check the motor speed. Most lathes need 1,500 to 3,000 RPM. The motor must be reliable. Look for motors with good reviews. Brushless motors are often better. They last longer and need less care.

Wiring And Speed Control

Wiring must be safe and neat. Use wires that can handle the motor power. 12 or 14 gauge wires are common. Connect wires firmly to avoid sparks. Speed control is key for precise work. Use a Variable Frequency Drive (VFD) for easy control. It changes the motor speed smoothly. Install a speed control knob. This helps you adjust speed while working. Always follow safety rules when wiring. Turn off power before you start.

Safety Measures And Precautions

Always wear safety goggles to protect your eyes. Gloves can shield your hands from sharp edges. Ear protection is important to guard against loud noises. Face shields offer extra protection for your face. Aprons keep your clothes safe from metal shavings. Closed-toe shoes protect your feet from falling objects. Make sure all gear fits well for maximum safety.

Always double-check that the lathe is turned off before making adjustments. Keep loose clothing and jewelry away from the lathe to avoid accidents. Secure the workpiece properly to prevent it from flying off. Use the correct tools for the job to ensure safe operation. Maintain a clean workspace to avoid slips and falls. Never leave the lathe unattended while it is running.

Testing Your Diy Lathe

First, check the alignment of the lathe. Use a dial indicator for this. Make sure the tool rest is stable. Adjust it if needed. The tailstock should be in perfect alignment. Test the spindle for any wobble. Correct any issues found. A well-calibrated lathe ensures precision.

Start with a soft metal for your first trial run. Observe the cutting process closely. Listen for unusual sounds. Check the smoothness of the cuts. Make tiny adjustments to the tool rest. Test again until satisfied. Repeat until the lathe runs perfectly.

Maintenance And Upkeep

Check the lathe’s alignment every week. Ensure the cutting tools are sharp and clean. Inspect the drive belts for wear and tear. Look for any loose bolts or parts. Lubricate all moving parts regularly.

Store the lathe in a dry place. Keep the work area clean. Cover the lathe when not in use. Replace worn-out parts immediately. Follow the manufacturer’s maintenance schedule.

Advanced Modifications

Adding CNC capability enhances precision. It also saves time. CNC stands for Computer Numerical Control. A small computer controls the lathe. You need a stepper motor, controller, and software. Install the stepper motor. Connect it to the controller. Then, link the controller to your computer. Use the software to program your cuts. This setup automates the process. Your lathe now makes precise cuts on its own.

Enhanced tooling options improve your lathe’s performance. Better tools make cleaner cuts. Carbide tools are a great upgrade. They are stronger and last longer. Another option is quick-change tool posts. They let you swap tools quickly. This saves time during projects. Boring bars help in making internal cuts. Knurling tools add texture to metal surfaces. These upgrades make your lathe more versatile.

Projects To Master With Your Lathe

Begin with simple tasks like turning cylindrical shapes. Practice creating basic tools such as punches or small hammers. Try making smooth finishes on your projects. Next, move on to creating simple threads. This helps in understanding how the lathe works. Completing these tasks will build your confidence.

After mastering the basics, try more challenging tasks. Create tapered shapes and intricate thread patterns. Experiment with different materials like brass or aluminum. Aim to produce precision parts for machines. Each task will improve your skill set and knowledge. Keep practicing and exploring new techniques.

Frequently Asked Questions

What Are The 5 Main Parts Of A Metal Turning Lathe?

The 5 main parts of a metal turning lathe are the bed, headstock, tailstock, carriage, and spindle.

How To Make A Simple Metal Lathe?

Build a simple metal lathe using a drill, metal rods, bearings, and a metal base. Assemble the parts securely.

Can A Metal Lathe Be Used For Woodturning?

Yes, a metal lathe can be used for woodturning. Ensure to use proper tools and adjust speeds.

Can You Turn Metal On A Lathe?

Yes, you can turn metal on a lathe. Lathes are ideal for shaping, cutting, and finishing metal parts.

Conclusion

Building a metal turning lathe can be a rewarding project. It requires patience and precision. Follow the steps carefully to ensure success. With dedication, you can create a reliable tool. This lathe will serve your metalworking needs for years. Start your project today and enjoy the satisfaction of crafting your own lathe.