Table of Contents

To align a wood lathe correctly for spindle turning, check the tailstock and headstock alignment for angular misalignment. Please make sure they’re parallel with each other. Next, ensure the lathe bed, spindle turning, headstock, and plane are level both lengthwise and sideways. Adjust the feet or shims as needed. Then, align the tool rest parallel to the lathe bed and adjust its height to match the workpiece centerline. Finally, check the tool rest’s distance to the workpiece point; it should be as close as possible without touching.

Adjusting the Tailstock for Precision

Role of the Tailstock

The tailstock in wood lathe alignment plays a crucial role in ensuring precision and accuracy during turning. It supports the other end of the workpiece opposite the headstock, maintaining stability and minimizing vibrations. Securing the workpiece between both ends prevents deflection or movement while being shaped.

In addition to stabilizing the workpiece, adjusting the tailstock is essential for achieving optimal precision. When not correctly aligned with the headstock, it can lead to turning length and diameter inaccuracies. This misalignment can result in uneven cuts and imperfections on your turned pieces.

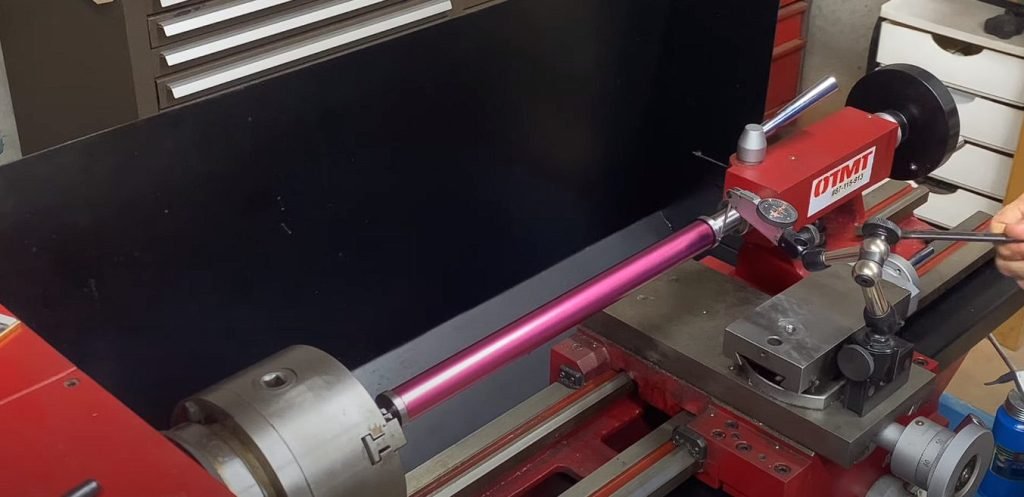

Understanding how to adjust the tailstock is vital for achieving precise woodturning results. To ensure proper alignment, you must check and adjust using appropriate tools, such as a dial indicator or a test bar. These tools help measure any misalignment between the tailstock quill and headstock spindle accurately.

Checking and Adjusting Alignment

To align your tailstock for precision, check its current position relative to the headstock using a dial indicator or test bar. If there’s any deviation from parallelism between these two components, you’ll need to make adjustments accordingly.

After identifying any misalignment, use adjustment screws on your lathe’s tailstock base to correct its position relative to the headstock. By carefully turning these screws an equal amount on each side while periodically rechecking with your measuring tool, you can gradually bring both components into perfect alignment.

I’ve found that taking time with this process pays off tremendously.

Attaching Face Plate to Lathe Correctly

Selecting Faceplate Size and Type

When choosing a faceplate for your woodturning project, consider the size and type that best suits your needs. A larger faceplate provides more stability when turning more significant pieces of wood, while a more minor one suits smaller projects. Different kinds of faceplates exist, such as screw-center or threaded center faceplates. For example, if you’re working on a large bowl, you may opt for a 6-inch screw-center faceplate to ensure secure mounting.

Matching the thread size of the lathe spindle with that of the faceplate ensures compatibility, preventing wobbling or instability during turning. Once you have selected the appropriate size and type of faceplate, it’s time to mount it securely onto the lathe spindle.

Mounting and Securing the Faceplate

To attach the faceplate properly, start by cleaning both the spindle threads and inside threads of the faceplate using a brush or cloth. Then, carefully align them before gently tightening them together by hand. Next, use an appropriate tool like a wrench or chuck key to secure the faceplate firmly onto the lathe spindle.

After securing it, rotate it manually to check for any signs of misalignment or wobbling. If everything looks stable and aligned with no noticeable imbalance, ensure accurate centering and alignment for balanced turning.

Taking time during this process helps me avoid mistakes that could affect my project later on.

Preparation of Bowl Blanks for Turning

When selecting wood species for bowl blanks, choosing dense, sturdy woods like maple, cherry, or walnut is essential. These woods are ideal for turning as they can withstand the forces exerted during the process. Consider the size of the bowl blank based on your lathe’s capacity and the desired final dimensions of your bowl.

Ensuring the wood is free from defects such as cracks or knots that could compromise its integrity during turning is crucial. The diameter and thickness of the blank should be sufficient to accommodate various designs while leaving room for adjustments during turning.

Roughing Out Bowl Blanks Using a Bandsaw or Chainsaw

Roughing out bowl blanks involves cutting them roughly circularly before mounting them on a lathe. A bandsaw or chainsaw can be used to achieve this initial shaping. Removing excess wood beforehand helps reduce material waste and minimizes stress on lathe tools.

Using a bandsaw allows for more precision in shaping bowl blanks. Cthana chainsaw due to its versatility in making intricate cuts. It also produces smoother surfaces, which aids in better sealing and drying later.

I find it helpful to mark out circles on my wood using templates before roughing out with a bandsaw. This ensures consistent sizing and reduces errors in shaping the bowl blank.

Preparing Bowl Blanks by Sealing, Drying, and Mounting Them on a Lathe

After roughing out, it’s essential to seal bowl blanks properly using solutions like wax emulsion or latex paint to prevent rapid moisture loss during drying. This helps minimize cracking and warping while ensuring an even drying process throughout the wood.

Once sealed, allow ample time for the bowl blanks to air dry gradually before mounting them securely into your lathe quill.

Preparing the Spindle for Turning

Spindle Inspection

Before aligning the wood lathe spindle and headstock, cleaning and inspecting it thoroughly is crucial to ensure no misalignment. Look for any signs of damage or wear on the spindle or drive shaft that could affect its performance. Any imperfections or irregularities in the way the point, center, and bed must be addressed before proceeding with alignment.

Inspecting the spindle, drive shaft, and bed involves checking for any debris or buildup hindering its proper function. Ensure the spindle, bed, and centers are free from dust, dirt, or other contaminants that might interfere with its rotation. A clean spindle and level bed are essential for optimal performance during turning operations.

I find it helpful to use a lint-free cloth and a mild solvent to carefully clean the spindle surface, removing any grime or residue that may have accumulated over time. This meticulous cleaning ensures the spindle bed is in prime condition for alignment and subsequent use.

Lubrication Process

Lubricating the wood lathe spindle and bed is essential in preparing it for turning tasks. Applying a suitable lubricant helps minimize friction and ensures smooth rotation during operation, preventing unnecessary strain on the machine components.

Using a high-quality lubricant designed explicitly for woodworking machinery, apply a small amount to the spindle’s surfaces and bed while ensuring even coverage across all contact points. This promotes seamless movement and reduces wear on the spindle, bed, and associated components.

In my experience, I’ve found that regular maintenance of woodworking tools prolongs their lifespan and contributes to safer and more efficient working conditions within my workshop.

Securing Wood on a Lathe for Stability

Choosing the Right Method

It’s crucial to choose a suitable bed based on your project requirements. Using a scroll chuck might be ideal if you’re working with irregularly shaped or unbalanced pieces. Conversely, a faceplate could provide better stability for bowl turning or larger workpieces.

In my experience, turning a large bowl from green wood with a faceplate helped prevent vibrations and provided the stability needed for safe and efficient turning. This insight can guide others in choosing the appropriate method for their projects.

Exploring Different Types

Exploring different types of lathe chucks and faceplates is essential for effectively securing wood. Scroll chucks are excellent for holding minor spindle work securely, while four-jaw chucks allow for adjusting each jaw individually to accommodate non-concentric shapes.

For example, when Iorking on intricate spindle turnings such as chair legs and table legs, utilizing a scroll chuck allowed me to secure the wood firmly without any wobbling during turning. This practical experience demonstrates how different types of chucks cater to varying project needs.

Ensuring Proper Tightening

Ensuring proper tightening and positioning of the wood prevents movement during turning. When mounting the piece onto the lathe using a chuck or faceplate, ensure it’s securely fastened before starting any cutting or shaping processes.

Always double-check that everything is secured tightly before any turning operation to avoid accidents caused by loose-fitting workpieces due to improper tightening techniques.

Steps for Using a Wood Lathe Effectively

Understanding Controls and Features

When using a wood lathe, it’s crucial to familiarize yourself with the various controls and features. This includes understanding the purpose of each control, such as speed adjustment and direction. For example, you need to know how to adjust the lathe’s speed based on the type of wood you’re working with.

It’s essential to become adept at identifying all parts of your lathe machine. The headstock, tailstock, tool rest, and motor are crucial components that require thorough understanding for practical use. By learning about these parts, you’ll be better equipped to operate your wood lathe safely and efficiently.

Positioning Tool Rest Correctly

One key aspect is mastering the correct techniques for tool rest positioning. The tool rest should be positioned close enough to support the cutting edge of your turning chisel but not so tight that it hinders smooth movement. Always ensure that it is securely tightened before starting any turning operation.

Understanding how different tools interact with the wood can significantly impact your turning results. Learning about spindle gouges, bowl gouges, scrapers, parting tools, etc., will help you choose the right tool for specific projects or cuts.

Experimenting with different tool rest positions helps me better understand their impact on my turning process.

Selecting the Right Wood for Turning Projects

Identifying Different Wood Characteristics Suitable for Turning

When lining up a wood lathe, it’s crucial to begin with the right type of wood. Look for woods that are specifically suitable for turning projects. Consider characteristics such as hardness, grain pattern, and moisture content. Hardwoods like maple and cherry are excellent choices due to their density and delicate grain patterns.

Selecting dry wood for turning, as wet or green wood can warp and crack during turning. Dry woods ensure stability in shape and minimize potential damage while working on the lathe. Pay attention to the moisture content of the selected wood; aim for a moisture level between 6% and % for optimal results.

Exploring Popular Wood Species Used in Woodturning

Turners favor several popular wood species due to their unique properties. For example, maple is known for its versatility and ability to showcase intricate details when turned on a lathe. Cherry offers a beautiful reddish-brown color with a smooth texture, ideal for creating elegant pieces.

Using different types of wood adds an exciting dimension to my turning projects. Each wood species has distinct characteristics influencing how it behaves on the lathe, allowing me to experiment with various textures and finishes.

Understanding Wood Lathe Alignment Basics

Key Components

Wood lathe alignment involves several vital components. These include the headstock, tailstock, tool rest, and the turning blank. The headstock holds the motor and spindle responsible for rotating the wood piece. The tailstock supports the opposite end of the turning blank.

Understanding how these components work together is crucial for achieving proper alignment. For example, if the tool rest isn’t positioned correctly about the turning blank, it can lead to inaccurate shapes or roughness on your turned piece.

Factors Affecting Alignment

Several factors affect wood lathe alignment, such as belt tension, center height adjustment, and tool rest positioning. Belt tension ensures power is efficiently transferred from the motor to the spindle, and center height adjustment determines how accurately cylindrical shapes are formed during turning.

For instance, improper center height adjustment might result in irregularities when creating spindles or other rounded objects on a lathe.

I’ve found that monitoring these factors can significantly improve my woodturning results by ensuring precise cuts and smooth finishes.

Vibration and Chatter

One of the most common issues resulting from poor alignment is vibration and chatter during woodturning operations. If improperly aligned, it may vibrate excessively or produce chatter marks on turned pieces due to unstable cutting conditions.

This can be frustrating as it affects the accuracy of returned items and surface finish quality.

Inaccurate Cuts

Poor alignment often leads to inaccurate cuts where dimensions don’t meet intended specifications. This problem arises when the critical components mentioned earlier are not appropriately aligned.

Ensuring proper alignment helps prevent wastage of material due to inaccurate shaping or sizing errors.

Conclusion: Mastering Wood Lathe Alignment

I’ve covered the essential steps for aligning a wood lathe, from understanding the basics of alignment to effectively using the lathe for turning projects. Ensuring the spindle, tailstock, and faceplate are adequately prepared and adjusted is crucial for achieving precision and stability during woodturning. Selecting the suitable wood and preparing bowl blanks are vital for successful turning projects. By mastering these alignment techniques, you’ll be able to elevate your woodworking skills and create high-quality turned pieces with confidence.

Now, it’s time to put these techniques into practice. Grab your wood lathe, select a quality piece of wood, and apply the alignment methods I’ve outlined. With patience and practice, you’ll soon become adept at aligning your wood lathe and producing impressive turned creations. Happy woodworking!

Frequently Asked Questions

How important is it to align a wood lathe correctly?

Aligning a wood lathe is crucial for achieving precise and safe turning. Proper alignment ensures that the workpiece rotates evenly, reducing vibrations and enhancing the quality of your turning projects.

What are the basic steps for securing wood on a lathe for stability?

Use tools like drive centers or faceplates. Ensure the piece is balanced and firmly attached to prevent wobbling during turning. Always follow safety guidelines when securing wood on a lathe.

Why is selecting the correct type of wood essential for turning projects?

Choosing suitable wood species affects both the ease of turning and the final appearance of your project. Hardwoods like maple or cherry are ideal for intricate details, while softwoods like pine may be more suitable for practice pieces.

How can I effectively prepare bowl blanks for turning?

Prepare bowl blanks by cutting them roughly into circular shapes before mounting them onto your lathe using appropriate accessories such as screw chucks or faceplates. This initial preparation ensures smoother and safer operations during turning.

What role does E-E-A-T play in mastering wood lathe alignment?

Understanding Expertise, Authoritativeness, and Trustworthiness (E-A-T) principles help you learn from reliable sources when mastering woodworking techniques such as aligning a wood lathe. Following reputable guides enhances your skills safely and effectively.