Table of Contents

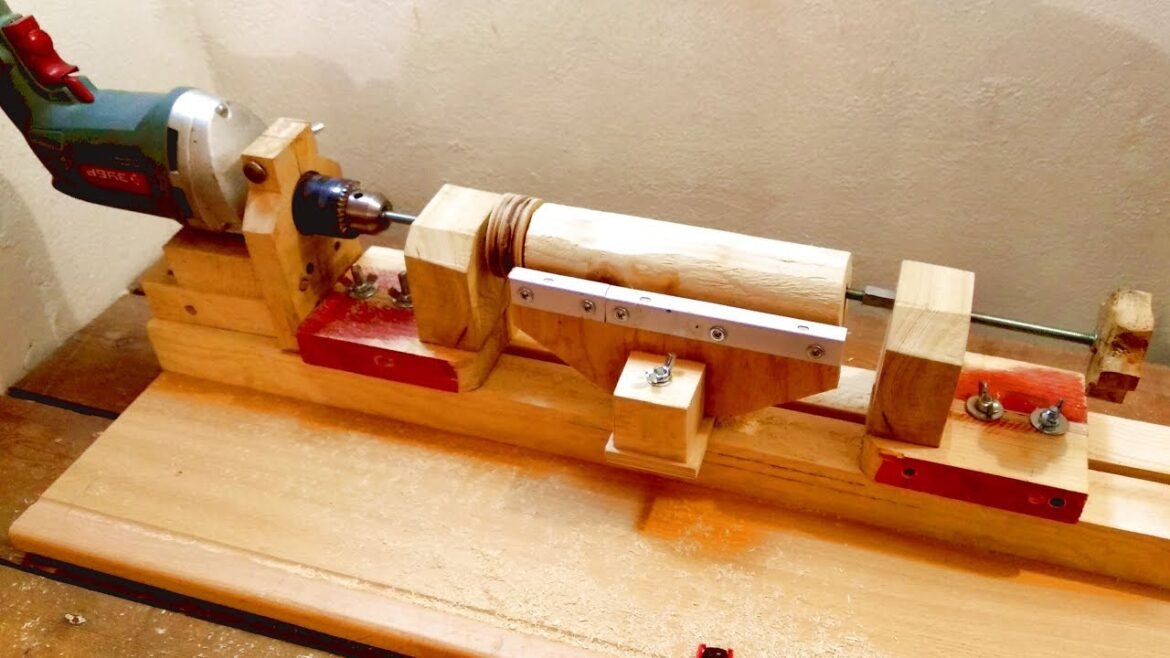

A homemade wood turning lathe is a cost-effective tool for woodworking enthusiasts. It enables customized projects and enhances craftsmanship.

Creating a homemade wood turning lathe can be a rewarding project for any woodworking hobbyist. It allows for personalized designs and ensures that the lathe meets your specific needs. Building your own lathe can also save money compared to purchasing a commercial one.

Essential components include a motor, spindle, and a sturdy frame. You can source parts from hardware stores or repurpose old machinery. This DIY approach not only provides a sense of accomplishment but also enhances your woodworking skills. Safety is crucial, so always wear appropriate gear and follow guidelines. A homemade lathe offers endless possibilities for creative projects.

The Allure Of Diy Wood Turning

DIY wood turning has a special charm. It lets you create unique items. You can make bowls, pens, or furniture parts. Many people find joy in this craft. It is both rewarding and therapeutic.

Embracing The Craft

Wood turning is an ancient craft. People have done it for centuries. When you make your own lathe, you connect with history. You also learn new skills. This craft requires patience and precision. It can be challenging but also very fulfilling.

With a homemade lathe, you control the entire process. You choose the wood and the tools. You can experiment with different techniques. This makes the craft even more engaging. It becomes a personal journey of learning and discovery.

Personal Satisfaction And Customization

Making your own lathe gives you a sense of accomplishment. You built a machine from scratch. This alone is very satisfying. You also get to use your creativity. You can design the lathe to fit your needs.

Customization is a big advantage. Store-bought lathes can be expensive. They also may not meet all your needs. With a homemade lathe, you can add features you want. You can make it larger or smaller. You can add special attachments.

Here are some customization options:

- Adjustable speed settings

- Different tool rests

- Customizable bed length

- Special chucks for holding wood

These options can make your wood turning projects easier and more enjoyable. You get to decide what works best for you.

| Store-Bought Lathe | Homemade Lathe |

|---|---|

| Expensive | Cost-effective |

| Standard features | Custom features |

| Limited sizes | Adjustable sizes |

Building your own lathe is not just about saving money. It is about creating something that is uniquely yours. It is about the joy of making and the pride in your work.

Credit: www.pinterest.com

Essential Tools And Materials

Creating a homemade wood turning lathe requires the right tools and materials. This guide will help you gather and choose the best supplies for your project.

Gathering Your Supplies

Before starting, ensure you have all the essential tools and materials. Below is a list to help you get organized:

- Lathe Motor: A powerful motor is needed.

- Lathe Bed: Use a sturdy metal or hardwood for the bed.

- Headstock: The headstock holds the wood.

- Tailstock: The tailstock supports the other end.

- Tool Rest: Allows you to rest your tools while working.

- Chisels: Essential for shaping the wood.

- Safety Gear: Includes goggles and gloves.

Choosing Quality Wood

Selecting the right type of wood is crucial for your lathe project. Here are some popular choices:

| Wood Type | Characteristics |

|---|---|

| Pine | Soft, easy to shape, and affordable |

| Maple | Hard, durable, and smooth finish |

| Walnut | Strong, beautiful grain, and dark color |

| Oak | Heavy, robust, and great for furniture |

Choose wood that fits your project needs and budget. Always inspect the wood for cracks or defects before using it.

Designing Your Lathe

Creating a homemade wood-turning lathe can be a rewarding project. The design phase is crucial for a functional and efficient lathe. This section will guide you through the essential steps.

Blueprints And Plans

Start by drafting blueprints and plans. These will serve as your road map. Use graph paper to draw detailed sketches.

- Front view

- Side view

- Top view

Include measurements for all parts. Ensure your plans are precise. Accuracy will make your build easier.

Space Considerations

Think about where you will place your lathe. You need enough space to work comfortably.

Measure your workspace. Compare it with your lathe plans. Make adjustments if needed.

| Lathe Part | Minimum Space Required |

|---|---|

| Bed | 6 feet |

| Motor | 2 feet |

| Tool Rest | 3 feet |

Consider ventilation and lighting. A well-lit and ventilated area is ideal.

Lathe Construction Steps

Building your own homemade wood turning lathe can be rewarding. Follow these steps to create a functional and sturdy lathe. This guide covers the essential steps, including constructing the base and assembling the rotating mechanism.

Building The Base

The base is the foundation of your lathe. It must be strong and stable. Start with a sturdy piece of wood or metal. Here are the steps to build the base:

- Cut the Base Material: Use a saw to cut the base to size. Ensure it is level.

- Attach Feet: Add rubber feet to the bottom. This will reduce vibrations.

- Reinforce the Base: Add metal brackets to strengthen the structure.

Assembling The Rotating Mechanism

The rotating mechanism is crucial for turning wood. It must be precise and smooth. Follow these steps to assemble it:

- Install the Motor: Secure the motor to the base. Use bolts to ensure it is tight.

- Attach the Spindle: Connect the spindle to the motor shaft. Ensure it is aligned.

- Fit the Bearings: Place bearings on both ends of the spindle. This allows smooth rotation.

Here’s a table summarizing the components needed for the rotating mechanism:

| Component | Purpose |

|---|---|

| Motor | Drives the spindle |

| Spindle | Holds the wood piece |

| Bearings | Allows smooth rotation |

Ensure all parts are secure and aligned. Testing the assembly is important. Run the motor and check for vibrations. Make adjustments as needed.

Electrical Considerations

Creating a homemade wood-turning lathe involves several electrical considerations. Ensuring your setup is both efficient and safe is crucial. This section will guide you through the essentials.

Motor Selection

Choosing the right motor is vital for your lathe. A powerful motor ensures smooth and consistent turning. Here are some key points to consider:

- Horsepower: A motor with 1-2 HP is ideal.

- Speed: Look for a motor with variable speed settings.

- Type: An AC motor is typically preferred for lathes.

Ensure the motor is compatible with your power supply. Check voltage and phase requirements. Using the correct motor can prevent safety hazards and improve performance.

Wiring For Safety

Proper wiring is crucial to ensure safety. Follow these steps for safe wiring:

- Use appropriate wire gauge: Thicker wires handle more current.

- Install a fuse: Protects the motor from overload.

- Ground the motor: Prevents electrical shocks.

Refer to this table for recommended wire gauges:

| Motor HP | Wire Gauge |

|---|---|

| 1 HP | 12 AWG |

| 2 HP | 10 AWG |

Using the right wire gauge prevents overheating. Always double-check connections and use quality materials. Safety should always be your top priority.

Fine-tuning And Calibration

Creating a homemade wood turning lathe is an exciting project. Fine-tuning and calibration are crucial steps. These ensure your lathe works smoothly and accurately. This section will guide you through the fine-tuning and calibration process. Learn how to adjust for precision and test your setup effectively.

Adjusting For Precision

Precision is key in wood turning. Start by checking the alignment of the headstock and tailstock. Use a straight edge to ensure they are perfectly aligned. If they are not, adjust them until they are.

Next, check the tool rest. It should be parallel to the lathe bed. Use a level to check this alignment. Adjust the tool rest if needed. Proper alignment ensures smooth and accurate turning.

Also, check the spindle speed. Use a tachometer to measure the speed. Adjust the speed control to achieve the desired RPM. Different woods and projects require different speeds. Refer to a wood turning speed chart for guidance.

Testing Your Setup

Once you have made the adjustments, it’s time to test your setup. Start by turning a simple piece of scrap wood. Observe the lathe’s performance. Look for any signs of vibration or uneven turning.

Check the finished piece for accuracy. Measure the dimensions and check the surface finish. If there are any issues, make further adjustments. Repeat the testing process until the lathe performs to your satisfaction.

Finally, ensure all moving parts are lubricated. This reduces friction and wear. A well-lubricated lathe operates more smoothly and lasts longer.

By following these steps, you can fine-tune and calibrate your homemade wood turning lathe. This ensures precise and enjoyable wood turning experiences.

Turning Your First Project

Embarking on your first wood turning project can be exciting and fulfilling. A homemade wood turning lathe opens up a world of creative possibilities. Whether you are new to woodworking or an experienced craftsman, turning your first project can be a rewarding experience. This guide will help you get started with selecting a starter project and mastering essential techniques.

Selecting A Starter Project

Choosing the right project is crucial. Start with something simple. Here are some ideal projects for beginners:

- Wooden Pens: Easy and quick to turn.

- Candle Holders: Simple shapes and designs.

- Bowls: Great for learning basic turning techniques.

These projects require minimal materials and offer a gentle introduction to wood turning. Ensure you have the right tools and safety gear.

Techniques And Tips

Mastering techniques is key to a successful project. Here are some essential tips:

- Tool Selection: Use sharp tools like gouges and chisels.

- Spindle Turning: Perfect for creating cylindrical objects.

- Faceplate Turning: Ideal for turning bowls and plates.

- Speed Control: Adjust the lathe speed for different wood types.

- Sanding: Sand your project for a smooth finish.

Always prioritize safety. Wear goggles and a dust mask. Keep your tools sharp and your workspace clean.

Here’s a quick reference table for the basic tools you’ll need:

| Tool | Purpose |

|---|---|

| Roughing Gouge | Shaping the wood |

| Spindle Gouge | Detail work on spindles |

| Parting Tool | Creating deep cuts |

| Bowl Gouge | Turning bowls |

| Scraper | Smoothing the wood |

By following these tips and techniques, you will be well on your way to turning your first project with confidence and precision.

Maintenance And Upgrades

Maintaining your homemade wood turning lathe is essential for its long life. Regular care and smart upgrades can boost performance. This guide will help you keep your lathe in top shape and enhance its capabilities.

Regular Care For Longevity

Proper maintenance starts with regular cleaning. Dust and debris can harm your lathe. Use a soft brush or vacuum to remove dust after each use.

Lubrication is key to smooth operation. Apply light machine oil to moving parts weekly. Check for loose bolts and tighten them monthly.

Inspect the belts and pulleys. Replace any worn or cracked belts immediately. Clean the pulleys to prevent slipping.

| Maintenance Task | Frequency |

|---|---|

| Clean dust and debris | After each use |

| Lubricate moving parts | Weekly |

| Check and tighten bolts | Monthly |

| Inspect belts and pulleys | Monthly |

Enhancements For Advanced Use

Upgrading your lathe can take your projects to the next level. Start with a better tool rest. A wider rest provides more stability.

Consider upgrading the motor. A powerful motor handles tougher woods with ease. Look for a motor with variable speed control.

Add a digital readout for precision. It shows the exact speed of your lathe. This helps in achieving consistent results.

- Tool Rest: Choose a wider tool rest for stability.

- Motor: Upgrade to a motor with more power and variable speed.

- Digital Readout: Install for precise speed control.

These upgrades can significantly improve your woodturning experience. They help in creating more intricate and accurate designs.

Safety Precautions

Wood turning lathes are powerful tools. They can create beautiful wooden pieces. But safety must come first. Proper precautions can prevent accidents. Follow these guidelines to stay safe while turning wood.

Protective Gear

Wearing the right protective gear is crucial. Always wear safety glasses. This protects your eyes from flying wood chips. A face shield offers extra protection.

Wear ear protection. Lathes can be loud and damage your hearing. Use earplugs or earmuffs to protect your ears.

Gloves can protect your hands. But ensure they are tight-fitting. Loose gloves can get caught in the machine. Wear a dust mask to avoid inhaling fine wood particles.

Safe Operation Practices

Before starting, check the lathe. Ensure it is in good working condition. Securely fasten the wood piece to the lathe.

| Practice | Importance |

|---|---|

| Check Lathe Condition | Prevents malfunctions |

| Fasten Wood Securely | Avoids accidents |

Start the lathe at a low speed. Gradually increase the speed as needed. Always keep your hands at a safe distance from the spinning wood.

Use proper tools for turning. Make sure they are sharp. Dull tools can slip and cause injuries.

Keep the work area clean. Remove any clutter. A tidy space reduces the risk of tripping or accidents.

Never leave the lathe running unattended. Always turn off the machine before leaving the area.

- Wear safety glasses

- Use ear protection

- Check lathe condition

- Fasten wood securely

- Start at low speed

- Keep hands at a safe distance

- Use sharp tools

- Keep work area clean

- Never leave lathe running unattended

Credit: www.instructables.com

Community And Resources

Engaging with the woodturning community can significantly enhance your journey. Utilizing the right resources and connecting with fellow enthusiasts can enrich your experience. Let’s delve into how you can tap into community and resources for your homemade wood turning lathe.

Joining Woodturning Forums

Joining woodturning forums is essential for growth. These forums are spaces where beginners and experts exchange ideas. They provide a platform for asking questions and sharing projects.

Some popular forums include:

- Woodturner’s Resource – A hub for tips and project showcases.

- Woodturning Online – Offers tutorials and community support.

- Turner’s Corner – Focuses on beginner-friendly advice.

Participating in these forums can help you learn new techniques. It also allows you to receive feedback on your work.

Expanding Skills With Tutorials

Learning from woodturning tutorials can rapidly improve your skills. Many experts share their knowledge through detailed guides and videos.

Here are some excellent resources:

| Resource | Description |

|---|---|

| YouTube Channels | Channels like Woodturning with Tim Yoder offer step-by-step instructions. |

| Blogs | Blogs such as Turning for Fun provide written tutorials and project ideas. |

| Online Courses | Websites like Craftsy offer structured courses with professional guidance. |

Utilizing these resources ensures continuous learning and skill enhancement. You can find tutorials that suit your learning pace and style.

Combining community interaction with tutorial learning creates a balanced approach. It allows you to grow steadily and confidently in the woodturning craft.

Showcasing Your Creations

Creating beautiful pieces on your homemade wood turning lathe is rewarding. But showcasing your creations can bring even more satisfaction. Displaying your work properly can attract more attention and even potential buyers. Here are some tips to help you showcase your woodturning projects effectively.

Photographing Your Work

Good photos highlight the beauty of your woodturning projects. Use a clean background to make your pieces stand out. Natural light works best for taking photos. It shows the true colors and details of the wood.

Avoid harsh shadows by using soft lighting. You can use a lightbox for smaller items. This ensures even lighting and no distractions.

Take photos from different angles. This gives viewers a complete look at your creation. Close-up shots show the fine details and craftsmanship.

Use a tripod to keep your camera steady. This prevents blurry images. A clear, sharp photo makes your work look professional.

Selling And Exhibiting

There are many ways to sell and exhibit your woodturning creations. You can start with local craft fairs and markets. These events attract people who appreciate handmade items.

Online platforms are also a great option. Websites like Etsy and eBay have large audiences. Create an online store to reach more potential buyers.

Social media is a powerful tool for showcasing your work. Share your photos on Instagram and Facebook. Use relevant hashtags to attract more viewers.

Consider displaying your work in local galleries or shops. Talk to shop owners about consignment opportunities. This can help you reach a local audience.

Build a website to showcase your portfolio. Include high-quality photos and descriptions of each piece. This provides a professional look and helps attract serious buyers.

Networking with other woodturners can also open up opportunities. Join local woodworking clubs or online forums. Sharing experiences and tips can lead to new ideas and sales.

Credit: m.youtube.com

Frequently Asked Questions

Can You Do Wood Turning Without A Lathe?

Yes, you can do wood turning without a lathe using hand tools like chisels, gouges, and carving knives. This method requires skill and patience.

Can You Use A Drill Press As A Lathe?

No, a drill press is not designed for use as a lathe. It lacks the necessary stability and precision.

What Are The Two Basic Methods Of Turning Wood On A Lathe?

The two basic methods of turning wood on a lathe are spindle turning and faceplate turning. Spindle turning shapes long, thin pieces along the grain. Faceplate turning shapes wider, flatter pieces across the grain.

What Is The Easiest Wood Turning Project?

A simple wood turning project is making a wooden pen. It requires minimal materials and tools. Beginners can complete it quickly.

Conclusion

Creating your own homemade wood turning lathe can be rewarding. It offers customization and cost savings. This DIY project enhances your woodworking skills. Enjoy the satisfaction of crafting your unique pieces. Embrace the creativity and functionality of your homemade lathe.

Start your woodworking journey today and experience the joy of handmade craftsmanship.