Table of Contents

Chuck Woodturning specializes in creating unique, handcrafted wood pieces. His work showcases exceptional skill and creativity.

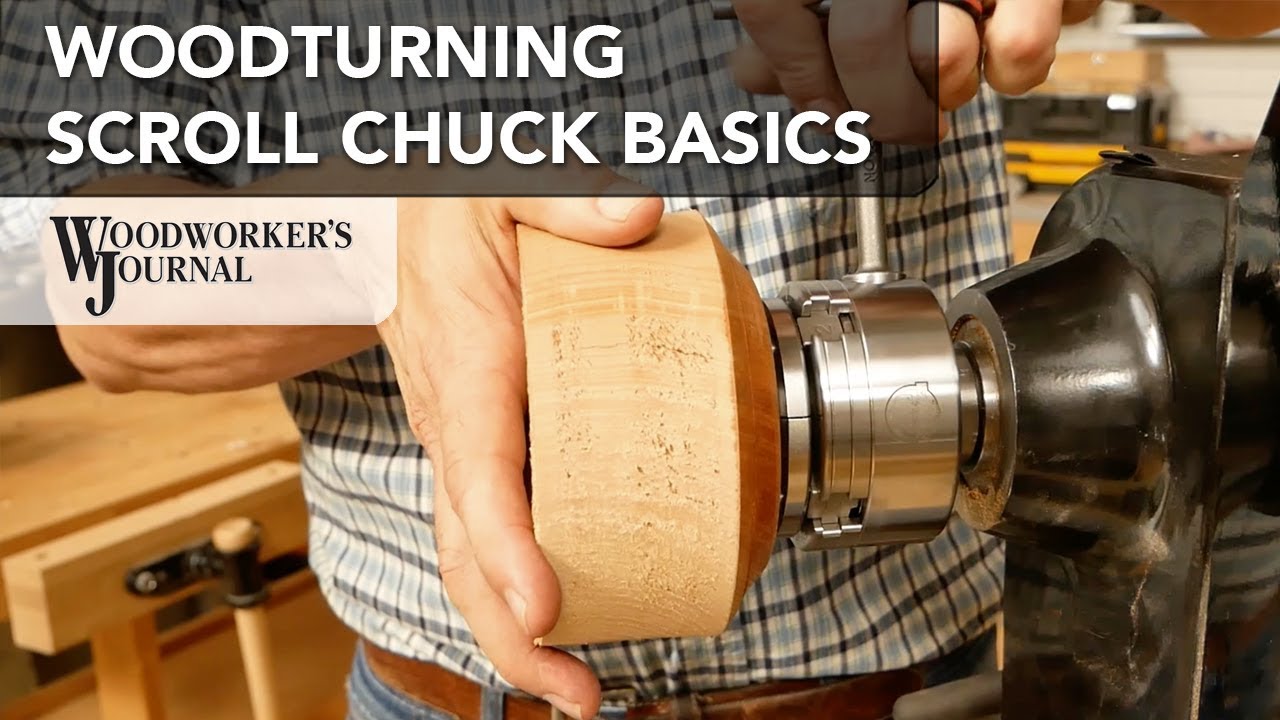

Woodturning is a captivating art form involving the crafting of wooden objects using a lathe. Chuck Woodturning stands out in this field, producing one-of-a-kind pieces that reflect both traditional techniques and innovative designs. Each creation by Chuck demonstrates a high level of craftsmanship, making his work highly sought after by collectors and enthusiasts.

From intricately designed bowls to elegant furniture, his portfolio displays a diverse range of woodturned items. This blend of artistry and skill ensures that Chuck Woodturning’s creations are not just functional but also visually stunning, adding a touch of elegance to any space.

Credit: www.axminstertools.com

Introduction To Chuck Woodturning

A chuck holds the wood on the lathe. It keeps the wood stable. This lets you shape the wood easily. Chucks come in various sizes. Each size fits different wood pieces. Some chucks have multiple jaws. These jaws grip the wood tightly. Using a chuck makes woodturning safer and more efficient.

Long ago, woodturners used simple spindle methods. These methods needed lots of skill. Then, the chuck was invented. Early chucks had only one jaw. Today’s chucks have up to four jaws. Modern chucks are more precise. They help make more complex designs. Chucks have changed woodturning forever.

Credit: www.youtube.com

Selecting The Right Chuck For Your Project

Choosing the right chuck is important. Project size matters a lot. Material type is another key factor. Some chucks work better with certain woods. Budget also plays a role. Expensive chucks may offer more features. Ease of use is crucial for beginners. A simple chuck can save time. Safety features should not be ignored. A secure chuck prevents accidents.

There are several types of chucks. Scroll chucks are very common. They are good for most projects. Four-jaw chucks offer more flexibility. They can hold odd-shaped pieces. Collet chucks are best for small, detailed work. Spigot chucks are used for holding spindles. Faceplate chucks are great for large, flat pieces. Each type has its own uses.

Getting Started With Your Chuck

First, gather all your tools. Make sure the chuck is clean. Tighten the chuck onto your lathe. Ensure it fits securely. Check if all parts move smoothly. Adjust the chuck as needed. Make sure it’s centered. This helps with even turning. Use a wrench to tighten. Double-check everything before starting.

Wear safety goggles to protect your eyes. Always wear a dust mask. This keeps your lungs safe. Tie back long hair. Avoid loose clothing. Keep your workspace clean. Clear away any clutter. Never leave the lathe unattended. Always turn off the machine when done. Keep a first aid kit nearby. Follow these steps to stay safe.

Basic Chuck Operations

Mastering basic chuck operations is essential in chuck woodturning. Securely grip your workpiece for precise shaping and detailed designs. Enhance your woodworking projects with improved stability and control.

Mounting Your Workpiece

Choose a piece of wood. Make sure it fits the chuck. Place the wood in the chuck. Tighten the chuck jaws. Ensure the wood is secure. Start the lathe slowly. Check if the wood spins evenly. Adjust if needed. Wear safety gear. Keep hands away from the spinning wood. Use proper tools for shaping.

Adjusting Chuck Jaws

Loosen the chuck jaws first. Move the jaws to fit the wood. Tighten each jaw evenly. Ensure the wood is centered. Spin the lathe by hand. Check for wobbling. Adjust the jaws if needed. Tighten the jaws securely. Test the setup by spinning the lathe slowly. Make any final adjustments. Always follow safety guidelines.

Advanced Chuck Techniques

Custom jaws can be made for specific projects. These jaws fit your chuck perfectly. Start by choosing the right material. Wood or metal are good options. Measure the dimensions accurately. Cut the material to the correct size. Shape the jaws to fit the chuck. Attach the jaws securely. Test them with small pieces first. This ensures safety and precision. Custom jaws improve your work quality. They also save time in the long run.

Cole jaws are great for finishing bowls. They hold the piece securely. This allows you to work on the bottom of the bowl. Fit the jaws to your chuck. Adjust the jaws to the size of your bowl. Place the bowl in the jaws. Tighten the jaws carefully. Make sure the bowl is centered. This prevents wobbling. Start your lathe at a slow speed. Increase the speed gradually. This ensures a smooth finish. Cole jaws make finishing easier and faster.

Maintenance And Care For Your Chuck

Clean your chuck regularly. Use a soft brush to remove dust. Ensure no dirt stays in the chuck. Avoid using water. Water can cause rust. Instead, use a dry cloth. Wipe it gently.

Lubricate your chuck often. Use light machine oil. Apply oil to all moving parts. This keeps the chuck smooth. Store the chuck in a dry place. Avoid damp areas. Dampness can cause rust. Keep it in a tool box. A tool box keeps it safe from dust.

Troubleshooting Common Chuck Issues

Slippage can be frustrating while turning wood. First, check the tightness of the chuck. Ensure it is securely fastened to the lathe. Use the correct size jaws for your workpiece. Always clean the chuck and workpiece to remove dust. Dust can cause slippage. If slippage continues, consider replacing worn out parts. Proper maintenance helps prevent these issues.

Alignment problems can ruin your work. Start by checking the tailstock and headstock alignment. Use a straight edge to ensure they are parallel. Adjust if needed. Inspect the chuck for any debris or damage. Debris can cause misalignment. Lubricate moving parts to ensure smooth operation. Regularly check the alignment to avoid future issues.

Credit: www.amazon.com

Projects To Master Chuck Skills

Start with simple projects like wooden pens. They are easy to make. Try making small bowls next. Focus on smooth shapes. Another idea is making candle holders. They can be great gifts.

Next, make spindle projects. These include table legs and chair spindles. Practice makes perfect. Always use sharp tools. Safety first!

Try making segmented bowls. They look beautiful. Another idea is hollow forms. They are tricky but rewarding. Consider making a lidded box. It requires precision.

Experiment with natural edge bowls. They showcase the wood’s beauty. Create intricate ornaments. They can be challenging. Always improve your skills. Stay patient and persistent.

Frequently Asked Questions

What Is A Chuck On A Wood Lathe?

A chuck on a wood lathe holds the workpiece securely. It allows precise shaping and turning operations.

What Chuck Do I Need To Turn Bowls?

For turning bowls, a 4-jaw self-centering chuck is ideal. It offers a secure grip and precise alignment.

What Does Chuck Do In Lathe?

A chuck in a lathe holds and rotates the workpiece securely. It ensures precision during machining operations like turning, facing, and drilling.

Do You Need A Chuck For Wood Turning?

A chuck isn’t mandatory for wood turning but highly recommended. It enhances precision, safety, and efficiency.

Conclusion

Mastering chuck woodturning opens up endless creative possibilities. With practice, you can craft stunning wooden pieces. Remember to choose the right tools and techniques for each project. By honing your skills, you’ll achieve impressive results and enjoy the art of woodturning.

Explore, experiment, and let your creativity shine through each unique piece.