Table of Contents

Before buying a portable wood lathe, consider the following key factors:

- Size and Weight: Check the lathe’s size and weight to determine its portability. Ensure it’s manageable for your workspace and easy to transport if needed.

- Power Source: Portable lathes can be electric or battery-powered. Choose one that suits your accessibility to power outlets or mobility needs.

- Speed Control: Look for a lathe with variable speed control. Different woodturning tasks require various speeds for optimal results.

- Swing Capacity: The swing capacity defines the workpiece’s maximum diameter. Ensure it meets your project requirements.

- Bed Length: The bed length determines the maximum length of wood you can turn. Longer beds accommodate more significant projects.

- Construction Material: Durable materials like cast iron or heavy-duty steel ensure stability and longevity.

- Tool Rest and Tailstock: Check the quality and adjustability of the tool rest and tailstock for precise wood shaping.

- Accessories: Assess included accessories, such as chisels, faceplates, and centers. Additional accessories can add value to your purchase.

- Brand and Reviews: Research the brand’s reputation and read user reviews to gauge product quality and customer satisfaction.

- Price: Compare prices across different models and brands, keeping your budget in mind.

- Warranty: Check for warranties and customer support options in case of issues.

Considering these factors, you can make an informed decision when buying a portable wood lathe that meets your specific needs.

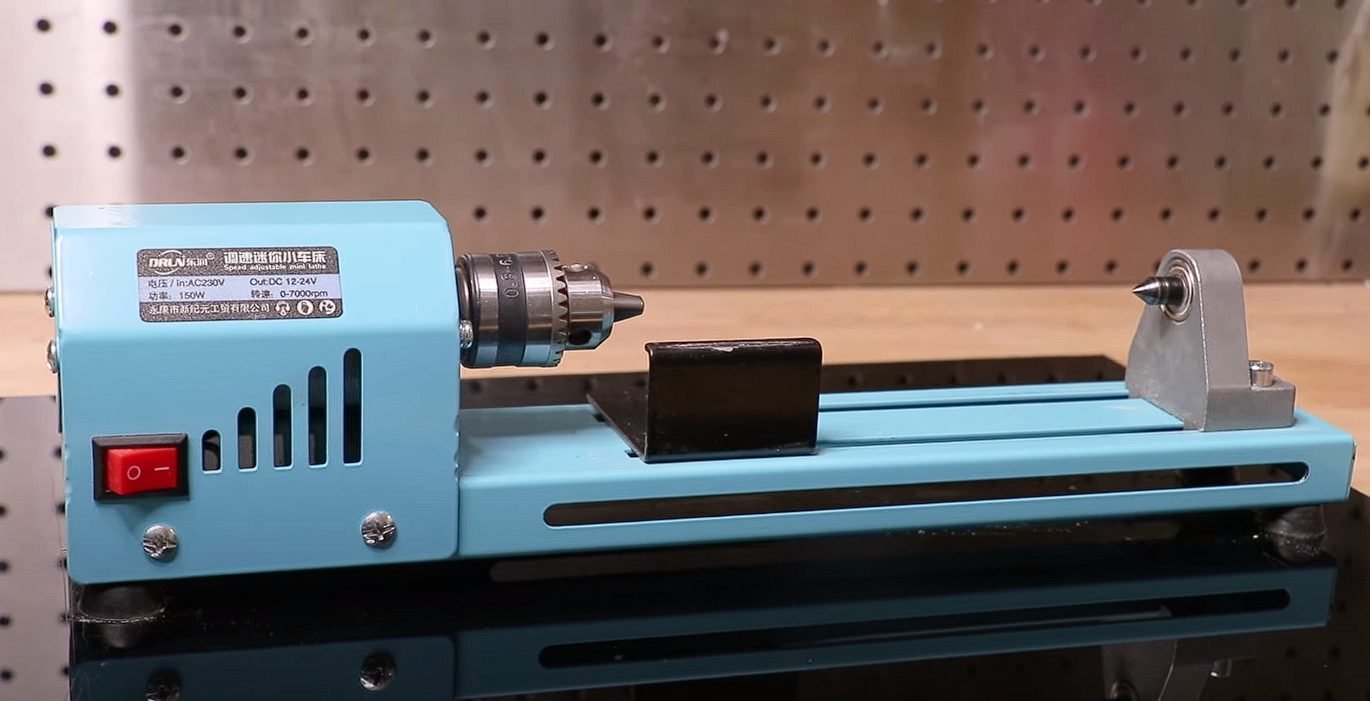

Portable wood lathes, including benchtop models, are essential for woodworking projects, offering versatility, convenience, and durability. These compact mini lathes enable easy transportation and setup, making them ideal for various work environments. Whether you’re a novice or an expert woodworker, portable wood lathes cater to all skill levels for turning projects and offer durability for bowls. With their user-friendly design and efficient performance, these mini lathes enhance the precision and quality of wood crafting.

Key Specifications of Portable Wood Lathes

Motor Power

A portable wood lathe’s motor power is crucial as it determines the machine’s performance in turning projects and bowls. A higher motor power allows for smoother and more efficient wood turning, especially when working with hardwoods, large workpieces, and bowls. For example, a portable wood lathe with a 1 HP motor can handle heavier and denser wood and bowls than one with a ½ HP motor.

A higher motor power ensures that the lathe can maintain consistent speed even when dealing with challenging projects such as turning thick table legs or large bowls. This means less effort is required from the user to achieve desired results, making woodworking tasks and bowls more manageable and enjoyable.

Swing Capacity

The swing capacity of a portable wood lathe indicates the maximum diameter of workpieces, including bowls, that can be turned without any obstructions. Knowing the swing capacity and bowls is essential when selecting a lathe based on specific project requirements. For instance, if you intend to turn table legs and bowls with larger diameters, you would need a lathe with an adequate swing capacity to accommodate those dimensions.

When considering various lathes, it’s essential to match the swing capacity to your intended projects, including bowls. This way, you ensure that your chosen machine can handle the size of workpieces you plan on creating without any limitations.

Distance Between Centers

The distance between centers in a portable wood lathe determines how long workpieces it can accommodate during turning operations. Understanding this specification is vital for planning and executing woodworking projects effectively. If you aim to turn longer items like baseball bats or chair spindles (such as table legs), choosing a lathe with an appropriate distance between centers is paramount for achieving accurate results.

Selecting a machine with sufficient distance between centers enables users to work on diverse projects without being restricted by length limitations.

Advantages of Mini Benchtop Wood Lathes

Space-saving Design

Portable wood lathes are designed to be compact and space-efficient, making them perfect for small workshops or limited workspace. Their smaller size allows woodworkers to maneuver easily around the lathe, maximizing the available area for other tools and equipment. This feature is especially advantageous for individuals with home-based workshops or hobbyists with minimal woodworking space.

These lathes also offer precise control over turning speed, allowing woodworkers to achieve smooth and accurate results. The ability to adjust the speed ensures that different types of wood can be worked on effectively, resulting in high-quality woodworking outcomes. For instance, when working on delicate or intricate designs, controlling the turning speed is crucial in preventing mishaps or errors during crafting.

Affordability for Hobbyists

One of the critical advantages of portable mini lathes is their affordability, making them an attractive option for hobbyists and DIY enthusiasts. Unlike larger industrial-grade lathes, mini benchtop wood lathes are more budget-friendly, offering essential features for various woodworking projects. This accessibility enables beginners or casual woodworkers to pursue their interests without a significant financial investment.

Having a portable wood lathe has allowed me to pursue my passion for woodworking without worrying about space constraints in my garage workshop. The convenience of moving it around as needed has genuinely enhanced my crafting experience.

Package Contents of Portable Wood Lathe Machines

Included Components

Portable wood lathe packages typically include the lathe itself, accessories, and a detailed user manual. The lathe is the primary component and is the core machine for turning wood. It’s compact and lightweight, making it easy to transport.

The accessories included in these packages are essential for various woodworking tasks. Commonly found accessories include tool rests, which support chisels during turning; faceplates, used for mounting workpieces; and drive centers, which secure the wood piece on the lathe while spinning.

These components comprise the fundamental package contents that enable users to start their woodworking projects immediately. They ensure that individuals have everything they need to begin crafting wooden items using their portable wood lathes.

Additional Tools

Some portable wood lathe packages contain essential components and tools like chisels or gouges. These additional tools enhance versatility by allowing users to create different shapes and designs on their turned wooden pieces.

Including these supplementary tools in a package can be incredibly beneficial, especially for beginners who might not still need an extensive collection of woodworking tools.

It is beneficial when portable wood lathe packages include additional tools. This gives me everything I need to start woodworking projects without buying extra supplies separately.

Importance of Variable Speed in Woodworking

Enhanced Versatility

Variable speed control is crucial when using portable wood lathes. This allows woodworkers to adjust the rotation speed according to different materials and turning techniques. Lower speeds are ideal for delicate work, such as intricate designs or finishing touches on a project, while higher speeds are suitable for roughing or shaping tasks. This enhanced versatility ensures that the lathe can precisely handle various woodworking projects.

Having variable speed options significantly enhances the versatility and precision of woodworking projects. For instance, when working on a small wooden bowl, you might need to start at a lower speed to turn the exterior before gradually increasing the speed to hollow out the interior. Making these adjustments without changing equipment allows smoother transitions between different project stages.

Woodworkers often encounter diverse types of wood with varying densities and characteristics. With variable speed control, they can tailor their approach based on each specific piece of wood, ensuring optimal results regardless of its properties.

Safety and Control

In addition to enhancing versatility, variable speed control also contributes to safety and control during woodworking processes. When turning large or unbalanced pieces of wood at high speeds, having precise control over the rotation is essential for preventing accidents or mishaps.

For example, if you’re working on a spindle that requires higher speeds for initial shaping but lower speeds for detailed carving, quickly adjusting the lathe’s speed without stopping your work ensures safety and efficiency.

Capacity Considerations for Your Wood Lathe

Swing Capacity

When choosing a portable wood lathe, it’s crucial to consider the swing capacity. The swing capacity refers to the maximum diameter of the lathe’s workpieces. For instance, you’ll need a lathe with a substantial swing capacity if you plan to turn large bowls or platters. Ensure that your selected portable wood lathe can accommodate your largest intended workpiece.

It’s essential to avoid purchasing a portable wood lathe with insufficient swing capacity. This could limit the size of projects you can undertake. For example, it won’t be possible if your lathe has a swing capacity of 10 inches and you want to turn a 12-inch bowl.

It is helpful to think about future projects when considering swing capacity. If I aspire to work on larger pieces, investing in a portable wood lathe with greater swing capacity would save me from limitations later.

Distance Between Centers

Another critical consideration is the distance between the centers of the wood lathe. This measurement determines how long a stock material can be turned on the machine without compromising stability or safety. If you anticipate working on longer spindles or table legs, ensure that your wood lathe offers adequate distance between centers.

For instance, if I plan on turning baseball bats or stairway balusters in my woodworking projects, having enough space between centers is essential for adequately maneuvering and securing more extended stock materials.

Ensuring Stability in Portable Wood Lathes

Sturdy Construction

Portable wood lathes need a sturdy construction to ensure stability during turning operations. The lathe base should be robust and well-built to withstand the forces exerted during wood shaping. This prevents unnecessary movement or vibration, providing a stable platform for woodworking.

Rubber feet or non-slip pads are essential components that help prevent excessive movement of the lathe. These features create friction between the lathe and the surface it’s placed on, minimizing any potential sliding or shifting during operation. This ensures the lathe stays firmly in place, contributing to its stability.

Workpiece Balancing and Securing

Balancing the workpiece is crucial for maintaining stability in portable wood lathes. A well-balanced workpiece reduces vibrations and enhances precision during turning operations. Properly securing the workpiece on the lathe further contributes to stability by preventing wobbling or displacement while being shaped.

Additional clamps or fixtures can enhance stability when working with portable wood lathes. These accessories provide extra support for securing the workpiece and sometimes even the entire lathe, ensuring a steady woodworking experience.

Selection Criteria for the Best Mini Wood Lathe

When choosing a portable wood lathe, it’s crucial to consider the motor power and speed range. A higher motor power allows for smoother turning of more significant or denser wood pieces, while a more comprehensive speed range provides versatility for various woodworking projects. For instance, if you often work with hardwoods or large diameters, opt for a mini wood lathe with at least 1/2 horsepower. On the other hand, if you frequently turn smaller items like pens or chess pieces, a lower horsepower may suffice.

Look for a machine with variable speed control to accommodate different turning needs. This feature enables you to adjust the speed based on the type of wood and project requirements. For example, reducing the speed is essential for precision and safety when working on intricate details or delicate materials.

Considering these aspects ensures that your portable wood lathe efficiently meets your specific woodworking demands.

The construction material of a mini wood lathe significantly impacts its stability and longevity. Seek lathes made from sturdy materials such as cast iron or heavy-duty steel. These materials provide stability during operation by minimizing vibrations and ensuring durability over time. Moreover, solid construction contributes to the machine’s overall sturdiness, preventing potential wobbling that can affect the quality of turned objects.

Furthermore, prioritize lathes with components designed for heavy usage without compromising performance. Look out for features like robust tailstocks and tool rests that can withstand prolonged use without wearing down quickly.

Before making a purchase decision regarding a portable wood lathe, take some time to review customer feedback online. Reading through reviews provides valuable insights into real-world experiences with specific models.

Applications and Versatility of Benchtop Wood Lathes

Turning Projects

Benchtop wood lathes are incredibly versatile and ideal for various woodworking projects. They excel in turning bowls, spindles, pens, and other small to medium-sized items. Whether crafting a decorative bowl or fashioning intricate chair legs, these lathes offer the precision and control needed for such projects.

Benchtop wood lathes support various methods, such as faceplate turning, spindle turning, and bowl turning. For instance, if you’re working on a spindle project like table legs or stair balusters, the lathe provides the right speed and tool rest configuration for this type of work.

Additional Functions

Apart from their primary function in woodturning projects, benchtop wood lathes can be adapted with accessories to perform additional tasks like sanding and drilling. This versatility means that one machine can handle multiple aspects of your project without needing separate tools or equipment. For example,

- Attaching a sanding disc allows for efficient smoothing of turned items.

- Precise hole drilling becomes possible with an adjustable chuck mounted on the lathe’s tailstock quill.

Having a portable wood lathe expands my woodworking capabilities and saves space in my workshop. It’s convenient to have one compact machine that can fulfill various functions rather than investing in individual specialized equipment.

Conclusion

In conclusion, portable wood lathes offer unparalleled versatility and convenience for woodworking enthusiasts. Understanding the key specifications, package contents, and selection criteria is crucial in making an informed decision. Variable speed and stability are non-negotiable factors that directly impact the quality of your woodturning projects. By prioritizing these aspects, you can ensure efficient and precise craftsmanship.

As you delve into the world of portable wood lathes, consider your specific woodworking needs and the scope of your projects. Take the time to explore the applications and capacity considerations to maximize the potential of your mini benchtop wood lathe. With the proper knowledge and a discerning approach to selection, you can elevate your woodworking experience and unleash your creativity with confidence.

Frequently Asked Questions

What are the key specifications to consider when buying a portable wood lathe?

When purchasing a portable wood lathe, it’s crucial to consider factors such as motor power, swing capacity, and variable speed settings. Evaluating the build quality and weight for portability is essential.

What are the advantages of mini benchtop wood lathes compared to larger models?

Mini benchtop wood lathes offer space-saving benefits, making them ideal for small workshops or hobbyists. They also provide precision turning capabilities on smaller projects and are generally more affordable than their larger counterparts.

How important is variable speed in woodworking when using a portable wood lathe?

Variable speed control is crucial in woodworking as it allows you to adjust the rotation speed based on different materials and turning requirements. This feature enhances safety, efficiency, and precision in your turning projects.

What factors contribute to ensuring stability in portable wood lathes?

Stability in portable wood lathes depends on features like a sturdy base, a secure workpiece mounting system, and vibration-dampening components. These elements help minimize wobbling or shaking during operation, resulting in smoother turns.

What applications can be accomplished with benchtop wood lathes due to their versatility?

Benchtop wood lathes can handle various woodworking tasks such as spindle turning, bowl turning, pen making, and creating intricate designs on small wooden pieces. Their versatility makes them suitable for both beginners and experienced artisans alike.