Table of Contents

Always use sharp hand tools for woodturning to reduce strain on the lathe. Second, avoid overloading it by not forcing the workpiece. Third, keep the lathe clean by regularly removing wood debris and dust. Fourth, lubricate moving parts, such as threads, as the manufacturer recommends to reduce friction. Finally, store it in a dry shop to prevent rust and corrosion. These ways will help prolong the life of your wood lathe for years.

Daily and Quarterly Wood Lathe Upkeep

Daily Maintenance

Daily maintenance tasks before and after each use are crucial to prevent a wood lathe from wearing out over the years. Before starting, check the tool rest position, secure workpiece tightness, and ensure the lathe bed is clean. After using the lathe, remove any wood chips or debris, lubricate moving parts with machine oil to protect them from dust, and cover the lathe.

Performing these daily maintenance tasks ensures your wood lathe operates smoothly, reduces vibration, and extends lifespan. Keeping the tool rest, floor, and workpieces in position and securing them properly reduces the risk of accidents during operation. Regular cleaning prevents sawdust buildup that could affect the performance of your wood lathe over time.

Quarterly Maintenance Schedule

In addition to daily upkeep, implementing a quarterly maintenance schedule for deeper cleaning and inspection is essential for keeping your wood lathe in top condition. This includes thoroughly cleaning all lathe components such as tailstock quills, headstock spindles, bearings, pulleys, floor, weight, vibration, etc., and checking for wear or damage on belts or drive systems.

This thorough inspection helps identify any potential vibration, floor, or weight issues early on before they become significant problems that can lead to extensive repairs or replacements. It also allows you to promptly address any wear and tear before it affects the precision or safety of your woodworking projects.

Importance of Dust and Debris Removal

Negative Impact of Dust and Debris

Dust, debris, and weight can significantly impact the performance of your wood lathe. When debris and weight accumulate in the moving parts on the floor, it can cause friction, leading to wear and tear. This wear affects not only the precision and lifespan of your lathe but also its weight and floor. Dust accumulation may lead to clogs, hindering the machine’s smooth operation.

Regularly removing dust and debris is essential for maintaining the optimal functionality of your wood lathe. Regularly cleaning these particles from your machine can prevent damage caused by their accumulation. Effective removal involves clearing out all areas where dust tends to settle, such as around bearings, belts, pulleys, and other moving parts.

Preventing Clogs and Damage

To effectively remove debris, use a vacuum or compressed air to clean hard-to-reach areas within the lathe. Consider installing a dust collection system that connects directly to your lathe’s point-of-origin for generating sawdust or shavings. This will help capture particles before they have a chance to accumulate on critical components.

Preventing clogs caused by accumulated debris is vital for ensuring that your wood lathe operates smoothly without any interruptions due to blockages. Regular maintenance also includes inspecting parts for signs of wear or damage resulting from debris buildup.

Preventing and Managing Rust on Your Wood Lathe

Understanding Rust Formation

Rust on a wood lathe is caused by the interaction of moisture and oxygen with the metal surfaces, leading to corrosion. This can result in detrimental effects such as reduced smoothness of operation, increased wear and tear, and potential damage to your wood lathe over time.

Moisture from humidity or improper storage conditions can accelerate rust formation on your lathe. When exposed to air, the moisture causes oxidation of the metal surfaces, leading to the familiar reddish-brown flaky substance known as rust. Dust and debris can exacerbate this process by trapping moisture against the metal parts.

Tips for Prevention

To prevent rust formation, your wood lathe must be stored in a dry environment with controlled humidity levels. To reduce moisture content, you can use a dehumidifier or silica gel packs in your storage area. Applying a thin layer of machine oil or using protective coatings like wax can also create a barrier against moisture and oxygen.

Regularly cleaning your wood lathe after use is also essential for preventing rust. Wipe down all metal surfaces with an oiled cloth or steel wool to remove any accumulated dust or debris that could lead to corrosion.

Techniques for Restoration

In case rust forms on your wood lathe despite preventive measures, you can utilize techniques such as steel wool, oil, or specialized rust removers designed for metal restoration. Gently rubbing the affected areas with steel wool helps remove surface rust without causing damage to the underlying material.

Lubrication and Tightening for Peak Performance

Role of Lubrication

Lubrication plays a crucial role in reducing friction and extending the life of your wood lathe. Proper lubrication helps to minimize wear and tear on moving parts, ensuring smooth operation. By reducing friction, lubricants also help prevent overheating and potential damage to components.

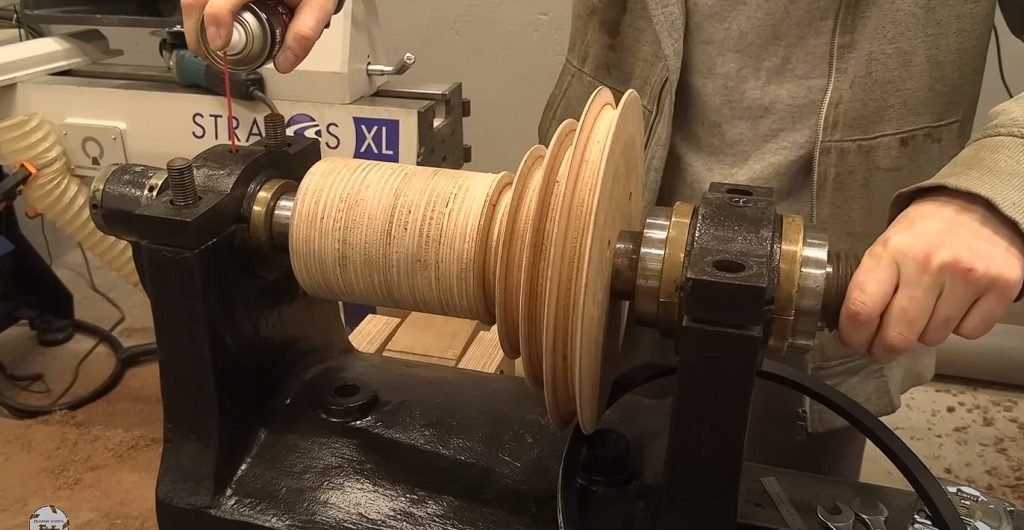

Regularly applying lubricant to critical areas such as the locking screw, belts, threads, and bolts is essential for maintaining optimal performance. The locking screw should be kept well-lubricated to ensure it moves smoothly without causing unnecessary strain on the machine. Applying lubricant to threaded components helps reduce friction during movement.

Checking and Tightening Components

Frequent checks and tightening of components are vital for keeping a wood lathe in top condition. Regular inspection allows you to identify any loose or worn-out parts that may cause excessive vibration or compromise safety during operation. Bolts securing various elements of the lathe should be checked routinely and tightened if necessary.

It’s essential to tighten and adequately align all components affecting the lathe’s performance over time. This includes checking for proper belt alignment, as misaligned belts can lead to increased wear on both pulleys and bearings.

I find that using compressed air when cleaning my wood lathe before applying lubricant ensures that no debris interferes with the effectiveness of the lubrication process.

Inspections for a Reliable Woodturning Experience

Thorough Inspections

Regular inspections are essential to prevent premature wear and tear on your wood lathe. By conducting thorough inspections, you can identify potential issues before they worsen, ensuring the longevity of your equipment—key areas to inspect include belts, bearings, motors, tool rest, and tailstock.

Inspecting the belts is crucial as worn-out or damaged belts can lead to inefficiency and even accidents during operation. Similarly, checking the condition of the bearings is essential to avoid unnecessary friction that could damage critical components over time.

Contribution to Longevity

Thorough inspections contribute significantly to safe operation and the longevity of your wood lathe. By identifying issues early on through regular checks, you can address them promptly before they escalate into more significant problems. This proactive approach not only ensures safety but also extends the lifespan of your equipment.

Regularly examining the motor, tool rest, and tailstock is vital in maintaining optimal performance while preventing premature wear and tear. A well-maintained engine operates efficiently without strain or overheating—factors that could otherwise contribute to its deterioration over time.

Personal Insights

I’ve found that dedicating just a few minutes before each woodturning session to inspect my lathe has helped me catch minor issues before they become major headaches. It’s like giving my lathe a quick “check-up” before putting it to work—a simple habit that has saved me from dealing with unexpected breakdowns or costly repairs down the line.

The Role of Proper Storage and Handling

Importance of Proper Storage

Proper storage is crucial to protect your wood lathe from damage. Storing your machine in a clean, dry, and secure environment shields it from moisture, which can cause rust and corrosion. Holding the lathe away from direct sunlight prevents UV damage to its components.

Keeping the lathe in a dedicated space within your workshop is essential, away from heavy foot traffic or potential collisions with other tools. Placing it on a sturdy workbench or stand helps distribute its weight evenly and reduces the risk of tipping over. Covering the lathe when not in use safeguards it from dust and debris that could affect its performance.

Safe Handling Practices

Safe handling practices are paramount for preventing accidents and minimizing wear on your wood lathe. When moving the lathe, ensure that all accessories are removed and properly stored to prevent damage or loss. Secure any loose parts, such as tool rests or tailstocks, before relocating the machine.

Proper lifting techniques are also crucial when repositioning the wood lathe within your workshop. Always lift with your legs instead of bending at the waist to avoid strain on your back. Furthermore, keeping flammable materials away from the lathe reduces fire hazards in case of sparks during operation.

I find that strategically organizing my workshop layout enhances safety and makes it more convenient to access my tools while working on various projects.

Safety Measures in Woodturning Workshops

Operating a Wood Lathe

When using a wood lathe, it’s crucial to follow the best ways to prevent it from wearing out. This includes ensuring that the lathe is adequately maintained and used correctly. Regularly inspecting the lathe for any signs of wear and tear can help prevent further damage.

Using sharp tools when operating a wood lathe is essential, as dull tools can cause unnecessary strain on the machine, leading to premature wear. Practicing proper techniques, such as avoiding heavy-handedness and sudden movements, can significantly reduce wear on the lathe.

Protective Gear

Wearing appropriate protective gear is essential when working with a wood lathe. This includes using face protection like safety goggles or a face shield to safeguard against flying wood chips or debris during turning. Wearing snug-fitting clothing without loose ends or accessories that could get caught in the machinery is also essential for personal safety.

I always make sure I’m wearing my safety goggles before starting any work on the lathe. It’s an easy step that provides peace of mind, knowing that my eyes are protected from potential hazards.

Safe Work Environment

Creating a safe work environment in your woodturning workshop is critical in preventing accidents and injuries. Keeping the workspace well-lit, organized, and free of clutter reduces the risk of tripping over objects or inadvertently coming into contact with hazardous materials while operating the lathe.

Moreover, maintaining good ventilation in your workshop helps ensure clean air circulation while working with various types of wood, which may produce harmful dust particles if inhaled repeatedly.

Wood Lathe Maintenance Basics

Essential Tasks

Regular maintenance is crucial for keeping a wood lathe in top condition. Cleaning the lathe regularly to remove dust and debris prevents wear and tear on its components. Lubricating moving parts such as the headstock, tailstock, and tool rest ensures smooth operation.

Performing routine checks for loose bolts or screws can prevent potential accidents while turning wood. Inspecting the motor and drive belt for any signs of wear or damage is also essential to avoid unexpected breakdowns during use.

Sharpening the cutting tools frequently is important, as dull tools can strain the lathe’s motor and other mechanical parts unnecessarily. Lastly, checking the alignment of the lathe’s components helps maintain precision in turning operations.

Regular maintenance tasks like cleaning, lubricating, inspecting for wear, and aligning components are essential to prevent significant issues that could lead to costly repairs later.

Preventative Benefits

Incorporating regular maintenance into your woodworking routine not only prolongs the life of your wood lathe but also ensures consistent performance when working on projects. By preventing significant issues through regular upkeep, you’ll save time and money that would otherwise be spent on repairing or replacing worn-out parts.

Moreover, maintaining a well-functioning wood lathe enhances safety by reducing the risk of malfunctions during operation. It also allows woodworkers to focus more on perfecting their craft than dealing with unexpected equipment problems.

Conclusion and Maintenance Checklist

It’s essential to take care of your wood lathe to keep it in good shape and working well. Clean it regularly, check it every few months, and prevent rust. Also, lubricate it properly, store it correctly, and follow safety rules. Doing these things can make your wood lathe last longer and get better project results. So, use the maintenance checklist and make taking care of your lathe regular. It will help keep your equipment safe and make woodworking easier. Have fun!

Frequently Asked Questions

How often should I lubricate my wood lathe?

Lubricate your wood lathe every 40-60 hours of use. Use a high-quality lubricant the manufacturer recommends to ensure smooth operation and prevent wear on moving parts.

What is the best way to remove dust and debris from my wood lathe?

Regularly clean your wood lathe using a soft brush, compressed air, or a vacuum with a small attachment. Ensure all areas, including the motor housing and crevices, are thoroughly cleaned to prevent buildup.

Is it necessary to inspect my wood lathe regularly?

Yes, regular inspections are crucial for identifying potential issues early on. Check for loose bolts, worn-out parts, and irregularities in performance. This proactive approach can help prevent significant problems and extend the life of your machine.

How can I prevent rust on my wood lathe?

To prevent rust, keep your wood lathe dry at all times. Apply a light coat of protective oil or wax after cleaning to create a barrier against moisture. Store your lathe in a dry environment away from humidity.

Are there specific safety measures I should take when using a wood lathe?

Always wear appropriate personal protective equipment, such as safety goggles and hearing protection, when operating the wood lathe. To avoid accidents, ensure that workpieces are securely mounted before turning on the machine.