Table of Contents

A texturing tool for metal turning creates detailed surface patterns on metal parts. It enhances both appearance and functionality.

Texturing tools are essential in metalworking for adding intricate designs and improving grip. These tools use various techniques to imprint patterns on metal surfaces, making each piece unique. Texturing enhances the aesthetic appeal and can also improve the mechanical properties of metal parts.

Common applications include decorative finishes, improved friction for handles, and detailed artwork on custom pieces. Choosing the right texturing tool depends on the desired pattern and the type of metal being worked on. Proper use of these tools can transform a simple metal piece into a visually striking and functional component.

Introduction To Metal Turning

Texturing adds unique patterns to metal surfaces. It enhances the look and feel of metal parts. These patterns can also improve grip and reduce wear. Different textures serve different purposes in metalworking. The right texture can make a big difference in the final product.

Texturing tools have changed a lot over the years. Early tools were simple and manual. Modern tools are more advanced and precise. Newer tools offer better control and consistency. They help metalworkers achieve better results. The evolution of these tools continues to improve the metalworking industry.

Basics Of Texturing Tool Design

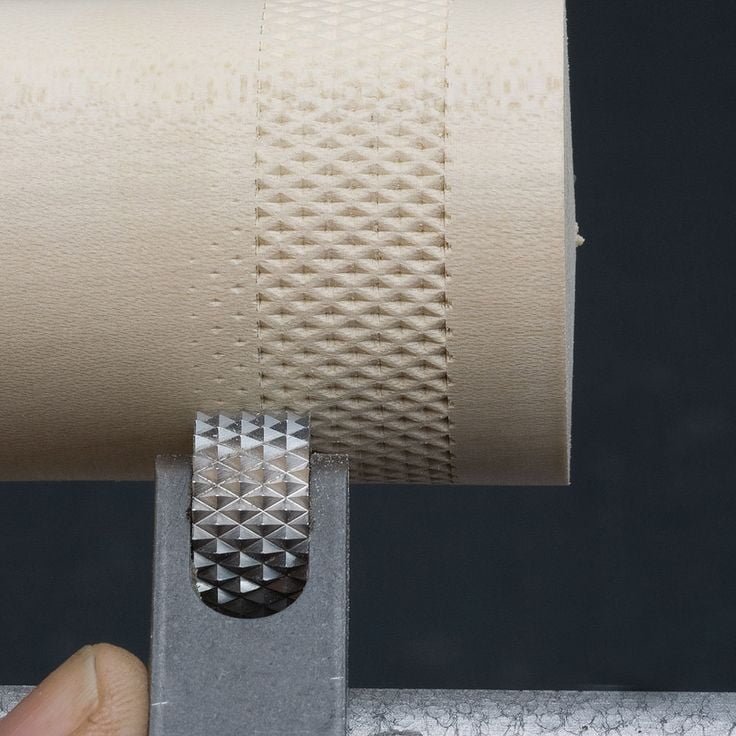

Texturing tools have many parts. Cutting edges are very important. They make patterns on metal. Handles help you hold the tool. Shanks connect the handle to the cutting edge. They must be strong. Adjustments let you change the cutting depth. This helps in making different textures. Bearings allow smooth movement. They reduce friction.

High-speed steel is often used. It stays sharp for a long time. Carbide is another choice. It is very hard and durable. Carbon steel is also good. It is tough and less expensive. Titanium can be used too. It is light and strong. Ceramics are hard and resist wear. Choosing the right material is very important. It affects the tool’s performance.

Types Of Texturing Techniques

Knurling involves pressing a pattern onto the metal surface. This process uses a special tool called a knurling tool. The tool rolls over the metal to create patterns. These patterns can be straight, angled, or diamond-shaped. Knurling enhances the grip on metal objects. It is commonly used on handles, knobs, and tools.

Embossing raises the metal surface to create a design. It uses a die or stamp to press the design onto the metal. This technique is often used for decorative purposes. Engraving, on the other hand, cuts into the metal surface. It creates fine lines and intricate patterns. Engraving is used for detailed designs and markings.

The Texturing Process

The metal workpiece must be clean and smooth. Any dirt or rust can ruin the texture. Use a cloth to wipe the metal. Ensure it is dry before starting. Secure the workpiece properly in the lathe. Check the alignment to avoid any mistakes. A firm grip is essential for safety. Always wear safety gear like gloves and goggles.

First, select the right texturing tool. Attach it to the lathe firmly. Set the lathe speed to a moderate level. Slowly bring the tool to the metal surface. Apply consistent pressure to create the texture. Move the tool steadily across the surface. Check the texture periodically to ensure uniformity. Once done, remove the tool and inspect the workpiece. Make adjustments if needed. Clean the area after completing the task.

Surface Quality And Finishing

Enhance surface quality and finishing in metal turning with specialized texturing tools. Achieve precise patterns and superior aesthetics on metal surfaces.

Achieving Desired Surface Roughness

Using the right texturing tool is key. Choose a tool that matches your metal type. Adjust the speed for better results. Keep the tool sharp at all times. Regular cleaning prevents buildup. Use a lubricant to reduce friction. Check the surface often during the process. Measure roughness with a profilometer.

Troubleshooting Common Texturing Issues

Uneven textures can be a problem. Make sure the tool is aligned. Inspect for any tool wear. Replace tools when necessary. Watch for overheating signs. Cooling systems help manage heat. Monitor vibrations during the process. Tighten all machine parts securely. Address any inconsistencies immediately.

Credit: www.youtube.com

Tool Maintenance And Care

Keep texturing tools sharp and clean. Use a soft cloth for cleaning. Lubricate moving parts often. Check for wear and tear. Replace worn-out parts quickly. Store tools in a dry place. Avoid moisture to prevent rust.

Clean tools after each use. Remove all metal shavings. Wipe with a dry cloth. Use oil to prevent rust. Store tools in a tool box. Keep in a cool, dry place. Avoid humid areas. Label tools for easy access.

Advanced Texturing Technologies

CNC machines make metal texturing very easy. They use precise movements to create patterns. These machines can work for hours without getting tired. They also reduce human errors.

Programming a CNC machine is quick. It saves time compared to manual methods. Different tools can be used with CNC machines. This makes them very versatile. Companies can produce many designs with these machines.

New technologies improve automated texturing every year. Robots now help in the texturing process. They are faster and more accurate than humans. Automated systems can also detect and fix errors quickly.

These systems are very efficient. They reduce waste and save materials. Many industries benefit from these innovations. The future of metal texturing looks very bright with these advancements.

Credit: www.mdpi.com

Case Studies And Applications

Texturing tools are widely used in the automotive industry. They enhance the appearance and functionality of metal parts. Car manufacturers use these tools to create unique patterns. These patterns help in reducing friction and improving aerodynamics. Textured surfaces can also help in better grip and safety. Many automotive companies invest in custom texturing. This gives them a competitive edge.

Artisanal crafters value custom texturing tools. These tools allow them to create unique designs on metal surfaces. Artists can express their creativity through intricate patterns. Custom texturing enhances the aesthetic appeal of handcrafted items. It also adds value to the finished products. Many artisans prefer handcrafted tools for precision. These tools help in achieving fine details on metal works.

Future Of Texturing In Metal Turning

Texturing tools are becoming more advanced. Smart tools can now adjust texture patterns automatically. Laser texturing is gaining popularity. It offers high precision and speed. Eco-friendly materials are being used in tool production. This helps in reducing the carbon footprint.

3D printing is revolutionizing texturing. Custom tools can be made quickly and cheaply. Complex textures are now easier to create. This technology allows for rapid prototyping. Manufacturers can test textures without high costs. This leads to more innovation in the industry.

Credit: www.highlandwoodworking.com

Frequently Asked Questions

How Do You Use The Wagner Texturing Tool?

Use the Wagner texturing tool by filling it with texture material. Adjust the nozzle settings. Spray the texture onto surfaces evenly. Clean the tool after use.

How Do You Use The Robert Sorby Texturing Tool?

To use the Robert Sorby texturing tool, secure the workpiece on the lathe. Adjust the tool’s angle and apply gentle pressure. Rotate the lathe at a low speed to create textures. Experiment with different angles for varied patterns. Always follow safety precautions.

How Does A Turning Tool Work?

A turning tool removes material from a rotating workpiece. It shapes and sizes the piece by cutting. The tool moves linearly while the workpiece rotates, creating precise dimensions.

What Is A Texturing Tool?

A texturing tool creates surface textures on materials. It enhances visual appeal and functionality in various applications.

Conclusion

Mastering texturing tools for metal turning can elevate your craftsmanship. These tools add unique, intricate designs. Enhance your projects with precision and creativity. Keep experimenting and refining your skills. The right tools and techniques will make your metalwork stand out.

Start exploring the endless possibilities today.