Table of Contents

The best metal turning involves precision machining to create accurate and detailed components. CNC lathes are commonly used for this purpose.

Metal turning is a crucial process in manufacturing industries. It ensures the production of intricate and precise metal parts. CNC lathes, with their computer-controlled operations, offer unparalleled accuracy and efficiency. This technology allows for consistent production, minimizing errors and reducing waste.

Metal turning caters to various sectors, including automotive, aerospace, and electronics. Skilled machinists oversee the operation, ensuring each component meets strict quality standards. The process also allows for customization, accommodating specific design requirements. Adopting advanced metal turning techniques enhances productivity and product quality, making it indispensable in modern manufacturing.

Introduction To Metal Turning

Precision is vital in metalwork. It ensures parts fit perfectly. Small errors can lead to big problems. Precision improves quality and safety. Skilled workers use precise tools. Machines help achieve accuracy. Precision reduces waste. It saves money. High precision is key in aerospace and automotive industries.

Metal turning has a rich history. It dates back to ancient times. Early lathes were simple. They used manual power. The Industrial Revolution changed metal turning. Machines became more advanced. Electric motors replaced manual power. Computer Numerical Control (CNC) revolutionized the process. Today, metal turning is highly automated. It is used in many industries. Metal turning continues to evolve. New technologies make it more efficient.

Credit: m.youtube.com

Essential Tools For Metal Turning

Precision and efficiency in metal turning depend on using the right tools. High-quality lathes, cutting tools, and measurement devices ensure top-notch results for any project.

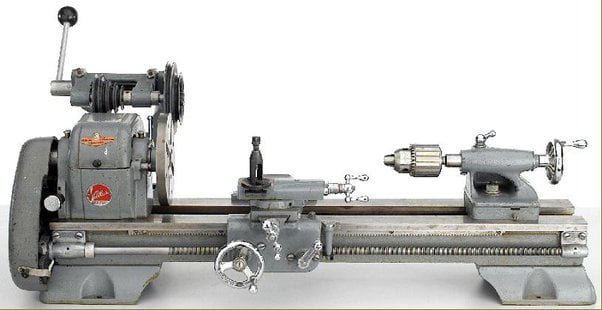

Lathe Selection For Precision Crafting

A good lathe is important for precision crafting. Choose one with sturdy construction. Look for variable speed control. Ensure it has a powerful motor. A digital readout helps with accuracy. Automatic feed options are useful. Select a lathe with multiple attachments. Safety features are crucial. Make sure it is user-friendly.

Cutting Tools And Their Specific Uses

Different cutting tools have specific uses. Carbide inserts are great for hard metals. High-speed steel works well for softer metals. Boring bars help create internal holes. Parting tools are used to cut off pieces. Threading tools make screw threads. Knurling tools create textured surfaces. Facing tools smooth out surfaces. Chamfering tools cut edges at angles.

Preparing For The Metal Turning Process

Choose the right metal for the job. Some metals are softer than others. Aluminum is easy to turn. Steel is harder but strong. Brass is good for precise work. Clean the metal before starting. Remove any dirt or rust. Measure the metal carefully. Use the right tools for cutting. Make sure the metal is secure on the lathe. This prevents accidents. Wear safety gear to protect yourself.

Place the lathe on a stable surface. Check that it is level. Adjust the lathe’s speed settings. Different metals need different speeds. Use sharp tools for better results. Dull tools can cause mistakes. Align the tool with the metal. This ensures smooth cuts. Keep the workspace clean. Remove metal shavings often. Lubricate moving parts for smooth operation.

Credit: m.youtube.com

Conventional Turning Techniques

Facing and taper turning are key in metalwork. Both methods help achieve smooth and uniform surfaces. Facing involves cutting metal to make it flat. Taper turning creates angled surfaces. This method is used for cones and similar shapes. Each technique provides precision and quality. Tools used include lathes and cutting tools. Accurate measurements ensure the best results. These methods are vital in many industries. They help create machinery parts and tools.

Thread cutting is essential for creating screw threads. This process makes precise patterns on metal rods. Special tools and lathes are needed. The operator must be skilled and careful. Threads are used in many products like bolts and screws. Accurate thread cutting ensures a tight fit. This technique is used in automotive and machinery industries. Quality threads mean strong and reliable connections.

Advanced Metal Turning Strategies

CNC lathes can create complex metal designs. These machines use computer controls. They can make precise cuts. This results in detailed shapes. Manual lathes can’t match this precision. CNC lathes work faster and more accurately. They reduce human error. This leads to better quality products.

Live tooling enhances the efficiency of CNC lathes. It allows for multiple operations in one setup. This reduces setup time and increases productivity. Live tooling can perform drilling, milling, and tapping. This eliminates the need for separate machines. It saves time and space. The result is a smoother workflow and better output.

Credit: www.amazon.com

Troubleshooting Common Turning Issues

Chatter and vibration can ruin metal turning. Ensure tools are sharp and secure. Use a steady rest to support long workpieces. Reduce the cutting speed if needed. Check for loose machine parts and tighten them.

Tool wear can be prevented by using the right cutting fluid. Always select the correct tool for the material. Inspect tools regularly for wear and replace them as needed. Proper feed rates and speeds are crucial. Avoid excessive heat buildup to protect both tools and workpieces.

Finishing Techniques For Turned Metals

Polishing makes metal shine. It removes small scratches. Grinding smooths the surface. Both are important for a nice finish. Polishing uses fine abrasive materials. Grinding uses rougher ones. Start with grinding. Then move to polishing. A smooth finish looks better. It also feels better to touch.

Protective coatings keep metal safe. They prevent rust and wear. Coatings can be paints or sprays. Some coatings are clear. Others add color. A good coating lasts long. It makes the metal look new. Applying a coating is easy. Just follow the instructions. Make sure the metal is clean first. A dirty surface can ruin the coating.

Safety Practices In Metal Turning

Wearing the right PPE is very important. Safety goggles protect your eyes from flying debris. Gloves keep your hands safe from sharp edges. Ear protection reduces noise that can harm your hearing. A face shield provides extra protection for your face. Steel-toed boots protect your feet from heavy objects. Aprons or protective clothing keep your body safe from sparks and hot metal.

Keeping your work area clean prevents accidents. Always remove loose objects that can cause trips. Ensure tools are stored properly. Regularly check your machines for wear and tear. Use guards and shields on equipment. Keep flammable materials away from your workspace. Proper ventilation is crucial to avoid inhaling harmful fumes.

Learning From The Masters

Expert turners have honed their skills over many years. They share their techniques and secrets freely. Many have detailed their work in case studies. These studies show the problems they faced and how they solved them. Reading these can boost your learning quickly.

Case studies also inspire new ideas. They give practical examples of what works. Learn from their mistakes and successes. This helps in improving your own work.

Workshops are a great way to learn. They offer hands-on experience. Experts guide you through each step. Many workshops also offer resources for further learning. These include books, videos, and online courses.

Joining a workshop connects you with other learners. Sharing experiences and tips with peers can be very helpful. It creates a community of learners. This community can support you in your journey.

Frequently Asked Questions

What Steel Is Good For Turning?

High-speed steel (HSS) and carbide-tipped steel are excellent for turning. They offer durability and precision. Stainless steel, especially 303 and 304 grades, also perform well in turning operations.

What Is A Good Metal Lathe To Buy?

A good metal lathe to buy is the Grizzly G0602. It offers durability, precision, and great value for money.

What Is The Easiest Metal To Lathe?

Aluminum is the easiest metal to lathe. It is soft, lightweight, and machines smoothly. Its excellent machinability makes it a favorite choice for beginners and professionals alike.

What Machine Is Used To Turn Metal?

A lathe machine is used to turn metal. It rotates the workpiece while cutting tools shape it. Lathes are essential in metalworking for creating precise cylindrical parts.

Conclusion

Mastering metal turning can elevate your craftsmanship and efficiency. Choose the right tools and techniques for optimal results. Regular practice and staying updated with industry trends will ensure your skills remain sharp. Happy turning!