Table of Contents

Metal turning tools are essential for shaping metals on a lathe. They are crucial for precision cutting and finishing.

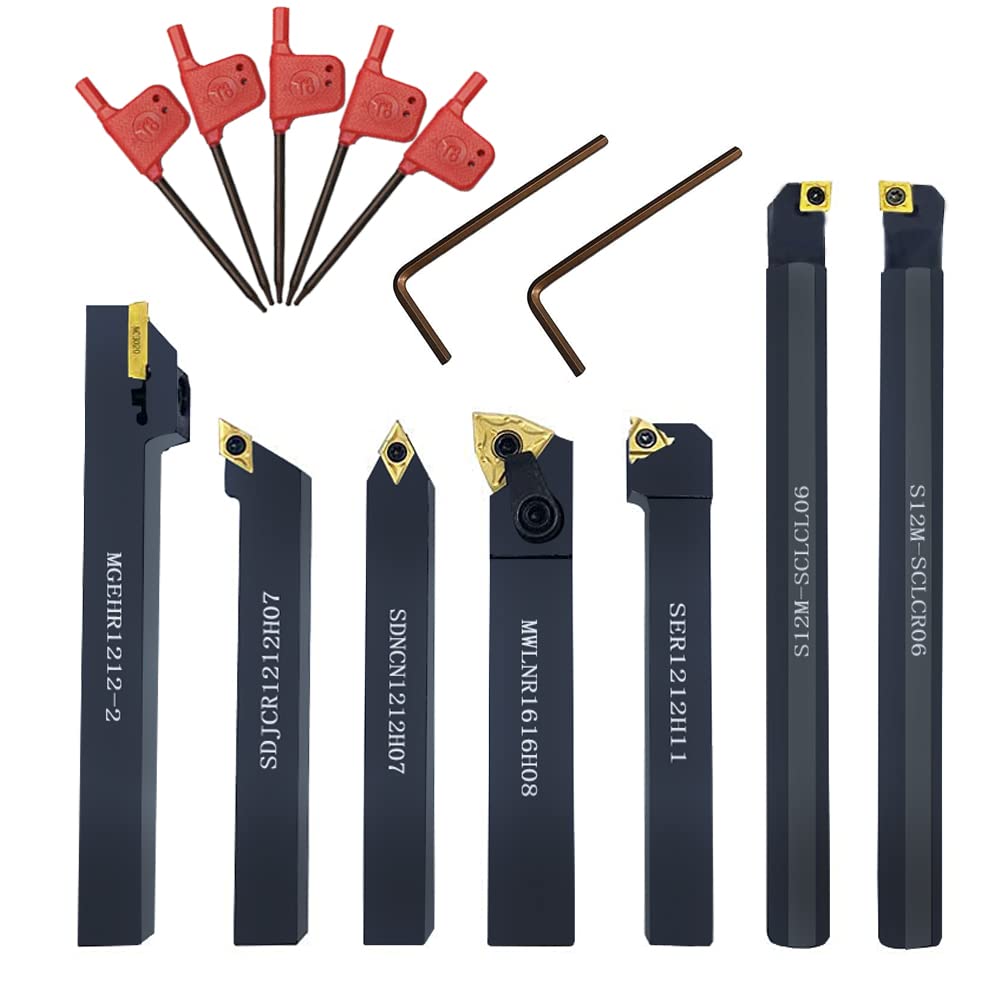

Metal turning tools play a vital role in machining processes, particularly in the manufacturing and engineering industries. These tools enable precise shaping, cutting, and finishing of metal workpieces on a lathe. They come in various types, each designed for specific operations, such as cutting, threading, or grooving.

Selecting the right tool ensures optimal performance and quality results. High-speed steel (HSS) and carbide tools are popular choices due to their durability and efficiency. Regular maintenance and proper usage of these tools can significantly extend their lifespan, ensuring consistent performance in metalworking tasks. Investing in quality metal turning tools can lead to better productivity and precision in your projects.

Credit: bigeasymart.com

Introduction To Metal Turning Tools

Metal turning tools are essential in the world of precision engineering. They shape and mold metal into desired forms. These tools are used in industries like automotive, aerospace, and manufacturing. Understanding their use can greatly improve efficiency and product quality.

The Art Of Metal Turning

Metal turning is a skillful process. It involves rotating a piece of metal while a cutting tool shapes it. This technique can create intricate designs and precise components. The art of metal turning requires a steady hand and sharp tools.

There are different types of metal turning processes:

- Facing: Creates a flat surface on the end of the workpiece.

- Parting: Cuts off a section of the workpiece.

- Grooving: Creates a groove in the workpiece.

Key Components In Precision Metalworking

Precision metalworking relies on several key components. Each plays a vital role in achieving accuracy and quality.

| Component | Description |

|---|---|

| Lathe | A machine that rotates the workpiece. |

| Cutting Tool | A tool that shapes the metal. |

| Chuck | Holds the workpiece in place. |

| Tailstock | Supports the end of the workpiece. |

Using the right components ensures precision and efficiency. Each part must be in good condition and properly aligned.

Maintaining metal turning tools is also crucial. Regular maintenance extends their lifespan and ensures consistent results. Clean and sharpen tools frequently. Inspect machines for wear and tear. Proper care leads to better performance and safety.

Categories Of Metal Turning Tools

Metal turning tools come in different types. Each type has a specific use. Understanding these categories helps in choosing the right tool. This ensures better precision and efficiency in your projects.

High-speed Steel Vs. Carbide Tools

High-Speed Steel (HSS) tools are commonly used. They are known for their durability. They can withstand high temperatures. This makes them ideal for cutting at high speeds.

Carbide tools are another popular choice. They are harder than HSS tools. They can cut faster and last longer. Carbide tools are great for tough materials.

| Feature | High-Speed Steel Tools | Carbide Tools |

|---|---|---|

| Durability | High | Very High |

| Heat Resistance | Good | Excellent |

| Cutting Speed | Moderate | High |

Specialty Tools For Unique Jobs

Specialty tools are designed for specific tasks. Each tool has a unique purpose. They help in achieving precision in complex jobs.

- Threading tools: Used for creating threads.

- Boring bars: Ideal for enlarging holes.

- Grooving tools: Perfect for cutting grooves.

Choosing the right tool is crucial. It ensures the success of your project.

Lathe Machine Basics

A lathe machine is essential for metal turning. It shapes materials with precision. Understanding its basics can enhance your metalworking skills.

The Heart Of Metal Turning

The lathe machine is the heart of metal turning. It’s used to rotate workpieces. This allows for precise shaping and cutting. The machine consists of several key components. Here are the main parts:

- Headstock: Houses the motor and gear system.

- Tailstock: Supports the workpiece’s opposite end.

- Bed: The base that holds all parts together.

- Carriage: Moves the cutting tool along the workpiece.

Setting Up For Success

Proper setup is crucial for effective metal turning. Here are steps to follow:

- Ensure the workpiece is securely clamped.

- Align the tailstock to support the workpiece.

- Adjust the tool post to the correct height.

- Set the lathe to the appropriate speed.

These steps ensure stability and precision. Let’s look at some tips for a successful setup:

| Tip | Details |

|---|---|

| Check Alignment | Ensure all parts are properly aligned. |

| Lubricate | Apply lubrication to reduce wear and tear. |

| Use Proper Tools | Ensure tools are sharp and suitable for the material. |

Following these tips can enhance your metal turning experience. Proper setup and maintenance lead to better results.

Essential Turning Tools And Their Uses

Turning tools are vital for anyone working with metal. These tools help shape, cut, and finish metal pieces. Understanding the different types of turning tools is crucial. Each tool has a specific function and purpose. This section will cover essential turning tools and their uses.

Cutting Tools: Shapes And Sizes

Cutting tools are the backbone of metal turning. They come in various shapes and sizes, each designed for a specific task. Here are some common cutting tools:

- Round Nose Tool: Ideal for general cutting and forming.

- Square Nose Tool: Excellent for straight cuts and facing operations.

- Parting Tool: Used to cut off pieces or make narrow slots.

- Thread Cutting Tool: Specialized for creating threads on metal pieces.

Each tool has its own unique shape. This shape determines its cutting ability. For instance, a round nose tool can perform a variety of cuts. On the other hand, a parting tool is more specialized.

Finishing Tools: Achieving Smoothness And Precision

Finishing tools are used to give metal pieces a smooth and precise finish. These tools are crucial for final touches. Here are some common finishing tools:

- Boring Bar: Used to enlarge holes and achieve smooth interiors.

- Reamer: Ensures that holes are perfectly round and smooth.

- Burnishing Tool: Provides a polished finish to the metal surface.

- Deburring Tool: Removes sharp edges and burrs for a clean finish.

Finishing tools are essential for the last step in metalworking. They ensure the final product is smooth and precise. A boring bar, for example, can make sure holes are exact in size. A burnishing tool, on the other hand, gives a shiny finish.

Advanced Tools For Complex Projects

Advanced metal turning tools are essential for complex projects. They provide precision, efficiency, and versatility. These tools help machinists achieve intricate designs and high-quality finishes. Let’s explore some of the advanced tools used in metal turning.

Boring Bars And Thread Chasers

Boring bars are essential for enlarging holes in metal workpieces. They ensure accuracy and smooth finishes. Machinists use them to create precise cylindrical shapes. Boring bars come in various sizes and materials. They are adaptable for different machining tasks.

Thread chasers are used to cut or repair threads on metal parts. They ensure accurate thread dimensions. Thread chasers are ideal for creating internal and external threads. They come in different shapes and sizes. They are crucial for maintaining thread quality in complex projects.

Grooving And Parting Tools

Grooving tools are used to cut grooves in metal workpieces. Grooves are essential for various mechanical applications. Grooving tools provide precise and clean cuts. They come in different widths and profiles. These tools are versatile for creating different groove shapes.

Parting tools are used to separate finished parts from the main workpiece. They ensure clean and accurate cuts. Parting tools are vital for achieving precise part dimensions. They come in various shapes and sizes. These tools are designed to minimize material waste.

| Tool | Function | Key Features |

|---|---|---|

| Boring Bars | Enlarging holes | Precision, smooth finishes, various sizes |

| Thread Chasers | Cutting/repairing threads | Accurate dimensions, internal/external threads |

| Grooving Tools | Cutting grooves | Precise cuts, various profiles |

| Parting Tools | Separating parts | Clean cuts, minimize waste |

Credit: www.pinterest.com

Tool Maintenance For Longevity

Proper maintenance of metal turning tools ensures they last longer. Regular care helps keep them sharp and efficient. In this section, we discuss essential maintenance practices.

Sharpening Techniques

Sharpening is crucial for metal turning tools. It keeps them effective and safe. Here are some sharpening techniques:

- Use a sharpening stone: Rub the tool on the stone at a 20-degree angle.

- Employ a honing guide: This keeps the tool at the right angle.

- Apply lubricant: Water or oil helps reduce friction.

- Check sharpness: Test by cutting a piece of paper.

Storage And Handling Best Practices

Proper storage and handling are vital for tool longevity. Follow these best practices:

- Keep tools dry: Moisture causes rust.

- Store in a tool chest: This prevents damage and misplacement.

- Use blade guards: These protect the edges from damage.

- Clean before storing: Remove debris and residue.

Regular maintenance enhances tool performance and lifespan. Following these tips ensures your metal turning tools stay in top shape.

Safety Measures In Metal Turning

Metal turning is a precise and complex process. Safety measures are essential to avoid accidents. Understanding and implementing these safety measures can save lives. Let’s delve into two key aspects of safety in metal turning.

Protective Gear Essentials

Wearing the right protective gear is crucial. Here are some essentials:

- Safety Glasses: Protect your eyes from flying debris.

- Face Shield: Provides additional face protection.

- Gloves: Shield your hands from sharp edges.

- Ear Protection: Reduce noise levels to protect your hearing.

- Apron: Wear a heavy-duty apron to protect your body and clothing.

- Boots: Wear steel-toe boots to protect your feet.

| Gear | Purpose |

|---|---|

| Safety Glasses | Eye protection |

| Face Shield | Face protection |

| Gloves | Hand protection |

| Ear Protection | Hearing protection |

| Apron | Body protection |

| Boots | Foot protection |

Operating Procedures To Prevent Accidents

Following proper operating procedures is vital. Here are some guidelines:

- Inspect the Equipment: Check tools and machinery before use.

- Secure the Workpiece: Ensure the workpiece is tightly secured.

- Use Correct Speed: Adjust speed according to the material.

- Keep Work Area Clean: Maintain a clean and organized workspace.

- Stay Focused: Always stay alert and focused on the task.

Accidents can happen if the equipment is not inspected. A tightly secured workpiece ensures stability. The correct speed prevents overheating and tool damage. A clean work area reduces risks of slips and falls. Staying focused helps in avoiding mistakes and injuries.

Credit: www.amazon.com

Future Of Metal Turning

The future of metal turning is bright and full of promise. New technologies are pushing boundaries. Automation and AI are transforming the industry. Let’s dive into these exciting changes.

Innovations In Tool Technology

Innovations in tool technology are setting new standards. Modern tools are more durable and precise. They last longer and require less maintenance.

Advanced materials like carbide and ceramics are used. These materials increase the efficiency and effectiveness of metal turning tools.

- Carbide tools: Highly resistant to wear.

- Ceramic tools: Excellent for high-speed operations.

- Coated tools: Offer increased longevity.

Smart tools are another innovation. They can monitor their own performance. This helps in reducing downtime and increasing productivity.

The Impact Of Automation And Ai

Automation and AI are revolutionizing metal turning. Robots are now handling repetitive tasks. This ensures consistency and accuracy.

AI algorithms help in optimizing the metal turning process. They can predict tool wear and suggest maintenance. This reduces costs and increases efficiency.

| Technology | Benefits |

|---|---|

| Robotics | Increased consistency and accuracy |

| AI Algorithms | Predicts tool wear and maintenance |

The future is all about smart factories. These factories use IoT and machine learning. They can adapt to changes quickly and efficiently.

Frequently Asked Questions

What Are The Common Metal Lathe Tools?

Common metal lathe tools include cutting tools, boring bars, threading tools, parting tools, and knurling tools.

What Is The Most Versatile Turning Tool?

The most versatile turning tool is the carbide insert. It offers durability, precision, and efficiency for various materials.

Which Tool Is Used For Turning On A Lathe?

The tool used for turning on a lathe is a lathe cutting tool. It shapes and sizes metal or wood.

How Do I Choose A Turning Tool?

Choose a turning tool based on material, cutting speed, tool geometry, finish quality, and cost. Ensure it fits your machine.

Conclusion

Mastering metal turning tools is essential for precise and efficient machining. Quality tools enhance performance and extend machine life. Investing in the right tools can save time and money. Always choose tools that fit your specific needs. Stay updated with the latest advancements for optimal results.