Table of Contents

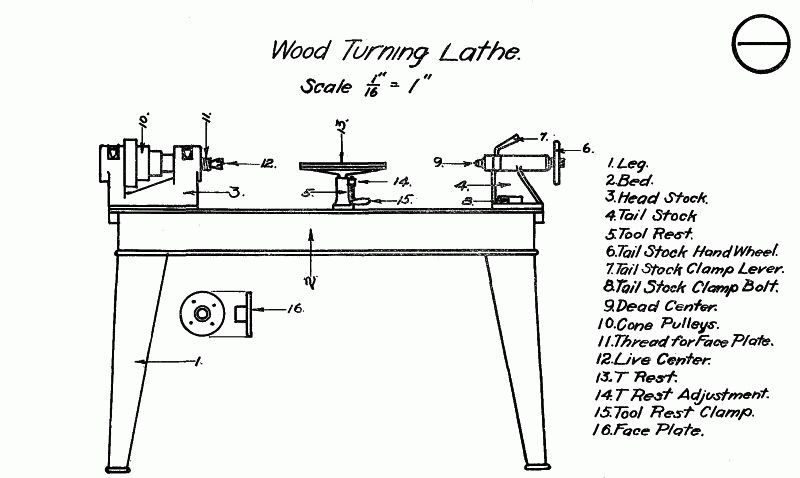

A wood turning lathe machine drawing illustrates the components and layout of the lathe. It helps in understanding the machine’s functionality.

Wood turning lathes are essential tools for shaping wood into various forms. These machines rotate the wood piece while a cutting tool shapes it. Understanding the drawing of a wood turning lathe machine is crucial for anyone working with or designing these tools.

The drawing typically includes details about the headstock, tailstock, bed, and tool rest. Each component plays a vital role in the machine’s operation. Clear and precise drawings ensure proper assembly and maintenance. They also help in troubleshooting and upgrading the machine. A well-drawn diagram enhances efficiency and safety in woodworking projects.

The Essence Of Wood Turning

Wood turning is an ancient craft that transforms raw wood into functional art. Using a wood turning lathe machine, artisans create beautiful shapes and designs. This process involves spinning the wood and shaping it with precise tools. It is both an art and a skill that has evolved over time.

Historical Significance

Wood turning has roots dating back to ancient Egypt. Artisans used simple tools to create bowls, spindles, and other items. The craft flourished during the Roman Empire. They enhanced the lathe machine with innovations. During the Renaissance, wood turning became a respected art form. Intricate designs and detailed work were highly valued.

Modern Wood Turning

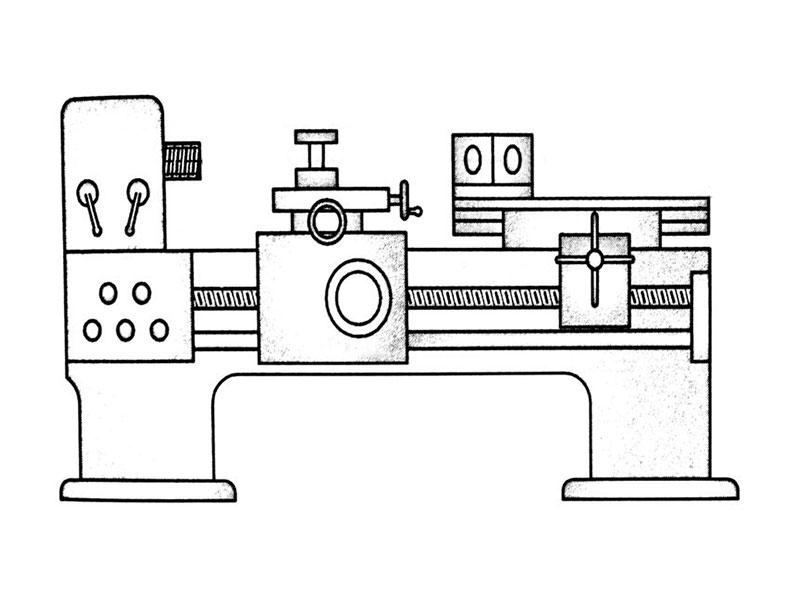

Today’s wood turning lathe machines are advanced and precise. They offer various features for both beginners and experts. The modern lathe machine allows for more intricate and detailed designs. Below is a comparison of traditional and modern lathe features:

| Traditional Lathe | Modern Lathe |

|---|---|

| Manual operation | Electronic controls |

| Basic tools | Advanced attachments |

| Simple designs | Complex patterns |

Modern wood turning involves various techniques and tools:

- Chisels and gouges for shaping

- Sandpaper for smoothing

- Finishes to protect and enhance the wood

Wood turning today is a blend of tradition and innovation. Artisans continue to push the boundaries of this timeless craft. Whether for hobby or profession, wood turning remains a cherished art form.

Credit: sawdustmaking.com

Lathe Machine Basics

Wood turning lathe machines are essential for woodworkers. They shape wood by rotating it against a cutting tool. Understanding the basics helps in producing precise and beautiful wood pieces.

Key Components

A wood turning lathe machine consists of several key components. Each part plays a crucial role in the machine’s operation.

- Headstock: This part holds the motor and spindle. It provides the power to rotate the wood.

- Tailstock: Positioned opposite the headstock. It supports the other end of the wood piece.

- Tool Rest: A horizontal bar where the cutting tools rest. It offers stability during cutting.

- Bed: The base of the machine. It connects the headstock and tailstock.

- Motor: Powers the spindle to rotate the wood.

Types Of Wood Lathes

There are various types of wood lathes. Each type serves different purposes and projects.

| Type | Description |

|---|---|

| Mini Lathes | Small and portable. Ideal for small projects like pens and bowls. |

| Midi Lathes | Medium-sized. Suitable for slightly larger projects. |

| Full-sized Lathes | Large and powerful. Used for big projects like table legs. |

Choosing the right type depends on your project needs. Always consider the size and power before making a decision.

Preparing For Lathe Machine Drawing

Before starting with your wood turning lathe machine drawing, it’s crucial to prepare adequately. Proper preparation ensures accuracy and efficiency. Let’s dive into the essential steps for a successful drawing session.

Selecting The Right Materials

Selecting the right materials is the first step. Choose high-quality paper and pencils. Use a mechanical pencil for finer lines. Keep an eraser handy for corrections. Consider using graph paper for precise measurements. The table below lists the materials you need:

| Material | Description |

|---|---|

| Pencil | Mechanical pencil for fine lines |

| Eraser | For corrections |

| Paper | High-quality or graph paper |

| Ruler | For straight lines |

Understanding Machine Anatomy

Understanding the machine’s anatomy is essential. A lathe machine has several parts:

- Headstock: Holds the spindle and motor.

- Tailstock: Supports the other end of the workpiece.

- Tool Rest: Supports the cutting tools.

- Bed: The base of the machine.

Knowing these parts helps in accurate drawing. Label each part clearly. Use diagrams for better understanding. Below is a simple code snippet to illustrate a basic lathe machine anatomy:

Headstock

|

| Tool Rest

|_________

/ \

/ \

| |

| Bed |

| |

|_____________|

|

Tailstock

Focus on each part’s dimensions. Ensure all parts are proportionate in your drawing. This preparation step ensures a clear and accurate drawing. Happy drawing!

Step-by-step Drawing Guide

Drawing a wood turning lathe machine can be exciting. This guide will help you create a detailed and precise drawing. Follow each step to get the best results. Let’s start with the basics and move to more intricate details.

Initial Sketching Techniques

Begin with a light sketch of the machine’s basic shape. Use a pencil for easy adjustments. Draw the main components first:

- Lathe Bed

- Headstock

- Tailstock

- Tool Rest

Ensure the proportions are accurate. Keep your lines light and smooth. Refer to reference images for better accuracy.

Adding Details And Precision

Once the basic shapes are in place, start adding details. Focus on the headstock first:

- Draw the spindle and motor.

- Add the handwheel and control buttons.

Move to the tailstock. Add the quill and handwheel. Make sure to include the locking mechanism. Draw the tool rest with its support arm. Add fine details like knobs and adjustment screws.

| Component | Details to Add |

|---|---|

| Lathe Bed | Draw the guide rails and mounting bolts. |

| Headstock | Include the spindle, motor, and control buttons. |

| Tailstock | Draw the quill, handwheel, and locking mechanism. |

| Tool Rest | Add the support arm and adjustment knobs. |

Review your drawing. Ensure all parts are proportional and detailed. Erase any unnecessary lines. Your wood turning lathe machine drawing is now complete.

Translating Drawing To Craftsmanship

Translating a drawing into a crafted wood piece is an art. It requires precision, patience, and skill. Wood turning lathe machines play a crucial role in this transformation. This section explores how to turn a drawing into a beautiful wood piece.

From Paper To Wood

The journey from paper to wood starts with a detailed drawing. This drawing includes all measurements and dimensions. You need to transfer these measurements accurately to the wood.

Tools needed:

- Calipers

- Ruler

- Marking gauge

Using calipers, you can measure the drawing. Then, transfer these measurements to the wood. Mark the wood clearly. This ensures accuracy during the turning process.

Steps:

- Measure the drawing.

- Transfer measurements to the wood.

- Mark the wood accurately.

Troubleshooting Common Issues

Sometimes, things go wrong during wood turning. Common issues include incorrect measurements, tool slipping, and wood cracking. Here are some solutions:

| Issue | Solution |

|---|---|

| Incorrect Measurements | Double-check all measurements before cutting. |

| Tool Slipping | Ensure tools are sharp and secure. |

| Wood Cracking | Choose high-quality wood and avoid knots. |

Always keep safety in mind. Wear protective gear and follow all safety guidelines. This ensures a smooth and successful wood turning experience.

Credit: www.stylecnc.com

Finishing Touches On Your Drawing

Adding the finishing touches to your wood turning lathe machine drawing can make a significant difference. This step ensures your design is polished, accurate, and ready for the next stages. Here, we discuss the final refinements and incorporating feedback to perfect your drawing.

Refining The Design

Refining the design involves looking at every detail. Make sure lines are straight and curves are smooth. Use tools like rulers and compasses to achieve precision.

- Check for any mistakes or inconsistencies.

- Ensure all components are aligned correctly.

- Make sure dimensions are accurate.

Use different colors for various parts. This helps in understanding the design better. Label each part clearly.

| Component | Color |

|---|---|

| Base | Blue |

| Spindle | Red |

| Tool Rest | Green |

Incorporating Feedback

Incorporating feedback is crucial in perfecting your drawing. Share your drawing with peers or mentors. Listen to their suggestions and make necessary changes.

- Gather Feedback: Ask for specific areas to improve.

- Analyze Comments: Look for common points mentioned.

- Implement Changes: Make adjustments based on useful feedback.

Doing this helps in identifying any overlooked aspects. It also brings new perspectives to your design.

Maintaining Your Wood Lathe

Maintaining your wood lathe ensures it works efficiently and safely. Regular maintenance can extend the life of your machine. Follow these simple steps to keep your wood lathe in top condition.

Routine Checks

Performing routine checks helps identify potential issues early. Here’s a checklist to guide you:

- Inspect the drive belt for wear and tear.

- Check the alignment of the headstock and tailstock.

- Ensure the tool rest is secure and free of damage.

- Clean the lathe bed to remove sawdust and debris.

These checks can prevent bigger problems down the road.

Longevity Tips

Want your wood lathe to last longer? Follow these tips:

| Tip | Action |

|---|---|

| Lubricate | Regularly oil the moving parts. |

| Sharpen Tools | Keep your cutting tools sharp. |

| Cover | Use a dust cover when not in use. |

| Store Properly | Store in a dry, cool place. |

These tips can extend the lifespan of your lathe.

Remember, a well-maintained lathe produces better woodwork. Keep your machine in good shape and enjoy smoother woodworking experiences.

Credit: www.youtube.com

Advanced Drawing Techniques

Advanced drawing techniques play a key role in creating precise and detailed designs for wood turning lathe machines. These techniques use modern tools like 3D modeling and animation to visualize movement. Let’s dive into these advanced methods.

3d Modeling

3D modeling allows you to create detailed and accurate representations of wood turning lathe machines. This technique helps in visualizing the final product from multiple angles.

- Precision: 3D models ensure every component is accurately depicted.

- Visualization: You can rotate and zoom in on different parts.

- Modification: Easily adjust dimensions and designs.

| Feature | Benefit |

|---|---|

| High Detail | Shows intricate parts clearly. |

| Realistic Views | Helps in better understanding the design. |

Animation For Visualizing Movement

Animation helps in visualizing the movement of the lathe machine. This technique shows how different parts move during operation.

- Clarity: Understand the machine’s function clearly.

- Efficiency: Detect potential issues before actual production.

- Presentation: Great for demonstrating to clients or team members.

Animation can be used to simulate:

- Spindle rotation

- Tool movement

- Material shaping

These techniques ensure your wood turning lathe machine designs are both functional and visually appealing.

Frequently Asked Questions

What Are The Two Basic Methods Of Turning Wood On A Lathe?

The two basic methods of turning wood on a lathe are spindle turning and faceplate turning. Spindle turning shapes long, narrow pieces like table legs. Faceplate turning is used for wider objects like bowls and plates.

What Are The Disadvantages Of Wood Turning?

Wood turning can be hazardous due to flying debris and dust. It demands significant skill and practice. Wood may crack or warp. Equipment and tools can be expensive. Maintenance is required to keep tools sharp and machines in good condition.

Some woods may cause allergies or respiratory issues.

How Much Does A Cnc Wood Lathe Cost?

A CNC wood lathe typically costs between $3,000 and $10,000. Prices vary based on features and brand.

What Are The Parts Of A Wood Lathe Machine?

A wood lathe machine has several key parts: headstock, tailstock, bed, tool rest, and motor. These components work together for effective woodturning.

Conclusion

Mastering wood turning lathe machine drawing enhances your woodworking skills. Accurate drawings lead to better craftsmanship. Practice and precision are key. Invest time in learning techniques. Your projects will show remarkable improvement. Embrace the art of wood turning, and watch your creations come to life with finesse.

Happy woodworking!