Table of Contents

A wood turning lathe stand provides stability and support for your lathe, ensuring precise and safe woodturning. It is crucial for both hobbyists and professionals.

A wood turning lathe stand is essential for anyone serious about woodturning. It offers a stable and secure base, which is vital for accurate work and safety. The stand minimizes vibrations, allowing for smoother and more precise cuts. Choosing the right stand depends on the size and type of lathe you use.

Many stands come with adjustable features to accommodate different heights and preferences. Some even include storage options for tools and accessories, enhancing your workspace organization. Investing in a quality lathe stand can significantly improve your woodturning experience, making it more enjoyable and efficient.

The Core Of Woodturning: Choosing A Lathe Stand

Choosing the right lathe stand is key in woodturning. A stable stand ensures smooth turning. Without a good stand, projects can fail. This guide helps you pick the best stand.

Material Choices For Durability

Materials impact the stand’s durability. Wood, steel, and cast iron are common choices.

| Material | Pros | Cons |

|---|---|---|

| Wood |

|

|

| Steel |

|

|

| Cast Iron |

|

|

Design Features For Stability

Design features are vital for a stable lathe stand. Look for wide bases and adjustable feet.

- Wide Base: A wide base offers more stability. It prevents the stand from tipping.

- Adjustable Feet: These help level the stand on uneven surfaces. Stability improves with proper leveling.

- Weight Distribution: Heavy stands provide better weight distribution. This reduces vibration during turning.

- Tool Storage: Built-in storage keeps tools handy. It also adds weight, enhancing stability.

Consider these features when choosing a lathe stand. A stable stand makes woodturning safer and more enjoyable.

Dimensions And Ergonomics: Crafting Comfort

Creating an efficient and comfortable workspace for wood turning requires attention to dimensions and ergonomics. A well-designed lathe stand can significantly impact your productivity and reduce fatigue.

Ideal Height For Efficiency

The height of your lathe stand is crucial for efficient work. The ideal height allows you to work without bending or straining. Experts recommend a height that aligns with your elbow when standing.

To find the perfect height, stand next to the lathe. Your elbows should be at a right angle when your hands are on the lathe. This position ensures minimal strain on your back and shoulders.

| Lathe Stand Height | User Height |

|---|---|

| 40 inches | 5’5″ – 5’8″ |

| 42 inches | 5’9″ – 6’0″ |

| 44 inches | 6’1″ – 6’4″ |

Workspace Layout For Easy Access

A well-organized workspace enhances accessibility and efficiency. Place frequently used tools within arm’s reach to avoid unnecessary movement. Arrange your workspace in a U-shape or L-shape for easy access to all tools and materials.

Consider the following layout tips:

- Keep the lathe at the center of your workspace.

- Place tool racks on either side of the lathe.

- Store wood blanks and materials nearby.

- Ensure adequate lighting for detailed work.

Use pegboards or magnetic strips to organize smaller tools. This setup keeps your workspace tidy and efficient.

Assembly Tips: Building Your Stand

Creating a sturdy wood turning lathe stand is crucial for stability. Follow these assembly tips to ensure a robust and reliable stand.

Step-by-step Assembly Guide

- Gather all materials and tools before starting.

- Lay out all parts and hardware on a clean surface.

- Start by assembling the base frame using the pre-cut pieces.

- Secure the legs to the base with screws and bolts.

- Attach the top platform to the base frame.

- Double-check all connections to ensure tightness.

- Use a level to confirm the stand is even and stable.

Tools And Hardware For Construction

- Drill

- Screwdriver

- Wrench

- Level

- Screws

- Bolt and nuts

- Wood glue

Ensure all tools are in good working condition. Proper tools make assembly easier and faster.

| Tool | Purpose |

|---|---|

| Drill | Making holes and securing screws |

| Screwdriver | Tightening screws |

| Wrench | Tightening bolts and nuts |

| Level | Ensuring stand is even |

Following these tips will help you build a strong and durable lathe stand.

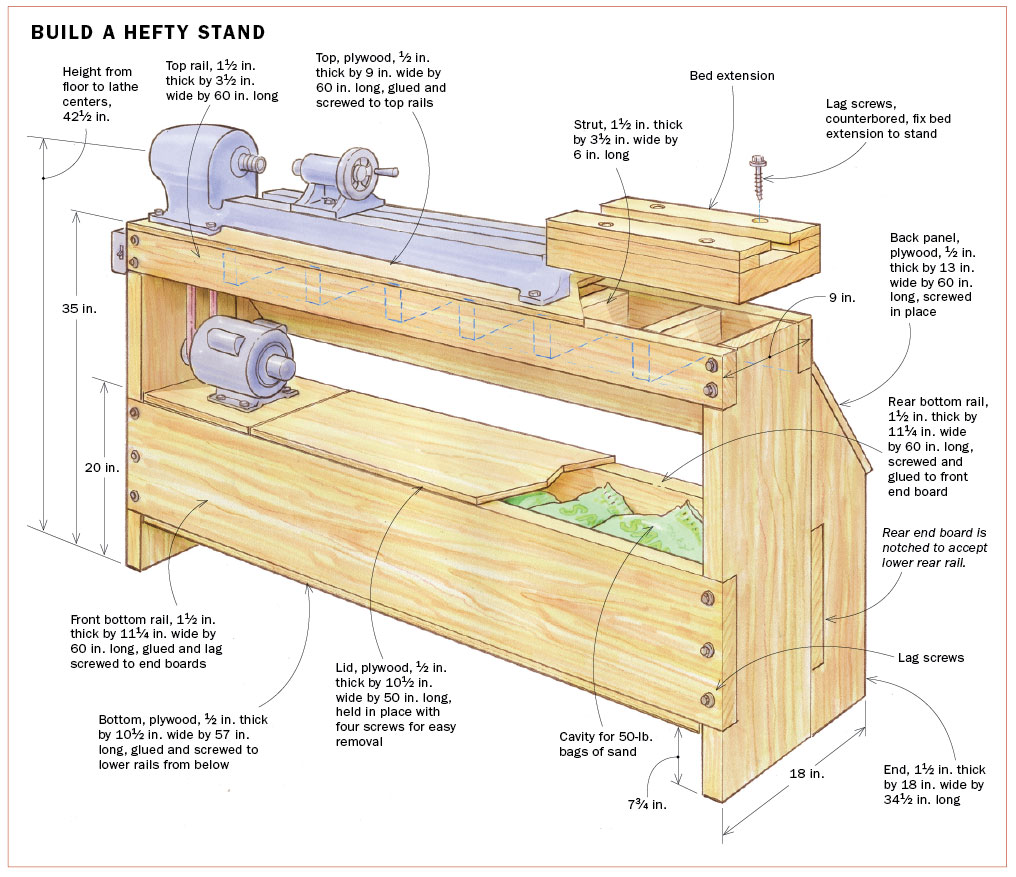

Credit: www.finewoodworking.com

Customization Options: Personalizing Your Stand

Customizing your wood turning lathe stand can enhance your woodworking experience. A personalized stand can cater to your specific needs, making your projects smoother and more efficient. This section will explore various customization options to tailor your lathe stand.

Adjustable Features For Flexibility

One of the key customization options is adding adjustable features. This flexibility allows you to modify the stand to suit different projects.

- Height Adjustment: An adjustable height feature ensures comfort during long hours of work.

- Angle Adjustment: Changing the angle of the stand can provide better control over your tools.

- Extendable Arms: Extendable arms offer additional support for larger wood pieces.

Adding Storage Solutions

Adding storage solutions to your lathe stand keeps your workspace organized. It ensures that all your tools are within reach.

| Storage Option | Benefits |

|---|---|

| Drawers | Keep small tools and accessories in an accessible place. |

| Shelves | Store larger items like wood pieces or sanding tools. |

| Tool Racks | Hang frequently used tools for quick access. |

Incorporating these storage solutions can transform your lathe stand into a more efficient workspace.

Securing The Lathe: Safety First

Wood turning can be a delightful hobby, but safety should always come first. Properly securing your lathe stand ensures stability and safety. Let’s dive into the key areas that need attention.

Mounting Techniques

Mounting your lathe correctly is crucial for safe operation. Begin by checking the stand’s base. Ensure it is level and sturdy. Use bolts to secure the lathe to the stand. This prevents any movement during operation.

Here are some steps for proper mounting:

- Place the lathe on the stand.

- Align the bolt holes with the stand.

- Insert the bolts and tighten them securely.

- Check the alignment once more.

Proper mounting minimizes the risk of accidents. This also enhances the precision of your work.

Reducing Vibration And Noise

Vibration and noise can be distracting and dangerous. It’s important to address these issues. A stable lathe stand reduces vibration significantly.

Here are some tips to reduce vibration and noise:

- Use rubber pads under the stand’s legs.

- Add weight to the stand to increase stability.

- Ensure all bolts and screws are tightly secured.

- Regularly check for loose parts and tighten them.

Reducing vibration improves the quality of your wood turning. It also protects your hearing and overall health.

Always prioritize safety when working with a lathe. Secure mounting and reducing vibration are key steps. Follow these guidelines to ensure a safe and enjoyable wood turning experience.

Credit: www.ashleygrenon.com

Maintenance And Upkeep: Longevity Of Your Stand

Maintaining your wood turning lathe stand is crucial. A well-kept stand lasts longer. Regular care prevents unexpected breakdowns. This section covers essential maintenance tips.

Regular Inspection Routines

Regular inspections help spot issues early. Follow these steps:

- Check for loose bolts and screws weekly.

- Inspect the stand’s stability monthly.

- Look for signs of wear and tear on the surface.

- Clean dust and debris after each use.

| Task | Frequency |

|---|---|

| Check bolts and screws | Weekly |

| Inspect stability | Monthly |

| Clean dust and debris | After each use |

Preventive Measures And Repairs

Preventive care keeps your stand in top shape. Follow these tips:

- Use anti-rust spray to prevent corrosion.

- Lubricate moving parts to ensure smooth operation.

- Store the stand in a dry place to avoid moisture damage.

- Replace worn-out parts immediately.

Address small repairs promptly. This prevents bigger issues later. Keep a toolkit handy for quick fixes.

Accessories And Add-ons: Enhancing Functionality

Enhance your wood turning lathe stand with the right accessories. These add-ons improve functionality and efficiency. Below are some must-have accessories.

Tool Rests And Tailstock Holders

Tool rests provide stability for your turning tools. They help in achieving precision cuts. Tailstock holders secure your workpiece in place. This ensures consistent results.

- Tool Rests: Keep your tools steady.

- Tailstock Holders: Secure your wood piece.

Both are essential for smooth and accurate woodturning.

Mobile Bases For Portability

Mobile bases make your lathe stand easy to move. This is useful for small workshops. You can rearrange your space quickly.

| Feature | Benefit |

|---|---|

| Lockable Wheels | Stability while working |

| Adjustable Height | Ergonomic comfort |

These bases provide flexibility and ease of use.

Credit: www.popularwoodworking.com

Case Studies: Exemplary Lathe Stand Designs

Exploring different lathe stand designs can inspire your next woodturning project. Whether you’re a professional or a DIY enthusiast, knowing the best designs can help. In this section, we’ll examine some standout lathe stands. You’ll find insights from professional woodturners and DIY projects reviewed.

Professional Woodturners’ Choices

Professional woodturners need sturdy and reliable lathe stands. They often choose stands made from solid hardwood for durability. Here are a few examples:

| Woodturner | Stand Material | Unique Features |

|---|---|---|

| John Smith | Maple Wood | Adjustable height, Tool storage |

| Jane Doe | Oak Wood | Heavy-duty, Vibration dampening |

John Smith prefers a maple wood stand. It offers adjustable height and tool storage. Jane Doe opts for oak wood. Her stand is heavy-duty and dampens vibrations effectively.

Diy Stand Projects Reviewed

Many woodturners enjoy building their own lathe stands. DIY stands can be cost-effective and tailored to specific needs. Here are a few reviewed projects:

- Easy to build

- Lightweight

- Cost-effective

- Environment-friendly

- Unique design

- Budget-friendly

A pine wood stand is easy to build and lightweight. It’s also cost-effective. A stand made from recycled materials is environment-friendly. It often features unique designs and is budget-friendly.

Frequently Asked Questions

How Tall Should A Wood Lathe Stand Be?

A wood lathe stand should be 36 to 44 inches tall. This height ensures ergonomic comfort and control while working. Adjust based on personal preference and height.

Should I Bolt My Wood Lathe To The Floor?

Bolting your wood lathe to the floor enhances stability and safety. It reduces vibrations, providing smoother operation. Secure your lathe for optimal performance.

What Is The Best Height For A Lathe Bench?

The ideal height for a lathe bench is around 36 inches. This height ensures comfort and better control. Adjust based on personal preference and ergonomic needs.

Why Should You Stand At The Right Height When Using A Lathe?

Standing at the right height ensures safety, precision, and comfort when using a lathe. It reduces strain and improves control.

Conclusion

Crafting a sturdy wood turning lathe stand enhances your woodworking experience. A well-built stand ensures stability and precision. Invest time in creating or choosing the right stand. It will significantly improve your projects. Enjoy smoother operations and achieve professional results with a reliable lathe stand in your workshop.