Table of Contents

Hollowing tools for woodturning are specialized instruments designed to remove material from the inside of a turned piece, such as bowls or vessels, allowing for the creation of thin-walled items and intricate shapes. These tools typically include a range of straight, bent, or curved shafts with cutting tips that can reach into deep or narrow spaces. Key types encompass hook-end hollowers, swan-neck hollowers for undercutting shoulders, and straight hollowers for general work. High-end systems may feature articulated arm mechanisms to provide control and leverage, and some are equipped with laser guides or camera systems to monitor the wall thickness. For optimal performance and safety, these tools must be used with steady rests and proper techniques to manage vibration and torque during the hollowing process.

Key Takeaways

- Choose High-Speed Steel: Consider using high-speed steel tools for woodturning due to their durability, sharpness, and ease of sharpening, which can enhance your woodturning experience.

- Select the Right Hollowing System: Explore basic hollowing systems and easily follow them to find the one that best suits your needs and skill level, ensuring a smooth and efficient woodturning process.

- Prioritize Easy Hollower #2: Understand the features and benefits of Easy Hollower #2, including its versatility and ability to handle various woodturning projects with precision and control.

- Compare Tools Carefully: When comparing hollowing tools, consider factors such as material, design, and user reviews to make an informed decision that aligns with your woodturning goals.

- Master Techniques for High-Speed Steel Tools: Learn and practice effective techniques for using high-speed steel tools to maximize performance and confidently create intricate wood-turning designs.

- Regular Maintenance is Key: Keep your hollowing tools sharp and well-maintained to ensure consistent results and a safe woodturning experience.

Comparing Hollowing Tools

Types of Tools

Woodturners use various hollowing tools for woodturning, including scrapers, gouges, and carbide-tipped tools. Each type offers unique benefits and is suitable for specific applications. For instance, scrapers are excellent for finishing cuts and smoothing uneven surfaces, while gouges excel at shaping the interior of a vessel or bowl. Carbide-tipped tools are known for their long-lasting sharpness and effectiveness in cutting through tough wood grains.

Experimentation with different types of hollowing tools is common among woodturners as they seek to find the most suitable ones for their preferences and projects. Some may prefer the versatility of gouges, while others may favor the ease of use provided by carbide-tipped tools. Personal experience plays a significant role in determining which tool works best for each individual.

High-Speed Steel vs. Others

High-speed steel hollowing tools offer exceptional hardness compared to other types of tool steel, such as carbon steel. This superior hardness allows them to withstand higher temperatures without losing their cutting edge, making them ideal for prolonged use during demanding turning projects.

In contrast, carbon steel tools require more frequent sharpening due to their lower hardness level. This fundamental difference makes high-speed steel an attractive choice for woodturners seeking durability and longevity in their woodworking equipment.

Easy Hollower vs Basic Systems

Personal preference heavily influences decision-making. While easy followers are designed for simplicity and control during operation, basic systems provide a more versatile approach by allowing users to switch between different cutting implements based on project requirements.

I have found that my preference often depends on the specific project I’m working on;

High-Speed Steel (HSS)

Purpose and Functionality

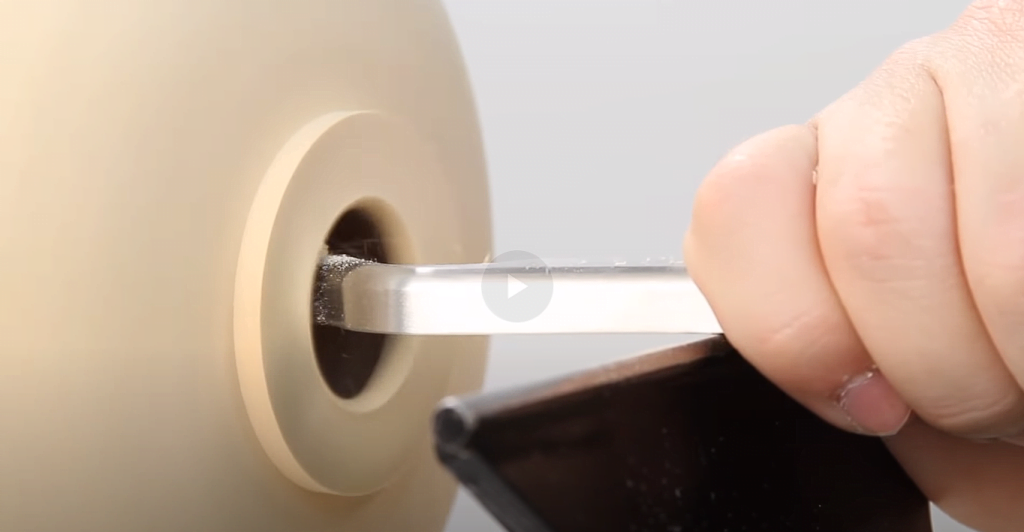

Hollowing tools for woodturning use a system to remove material from the inside of turned wooden objects. They are essential for creating hollow forms like bowls, vases, and boxes. These tools come in various shapes and sizes to accommodate different turning projects, offering versatility to woodturners.

One significant benefit of high-speed steel is its superior hardness, allowing extended use without frequent sharpening. This durability makes them a cost-effective choice in the long run. Moreover, these tools can withstand the high temperatures generated during the woodturning process, ensuring longevity even under intense heat conditions. As a result, they provide excellent cutting performance that leads to smoother finishes on turned wooden objects.

Techniques for Use

Woodturners employ various techniques when using hollowing tools, including scraping, shearing, or slicing cuts. Proper tool positioning and body movement are crucial in achieving desired results with these tools. By practicing good technique and understanding how different cuts affect the wood’s grain orientation, tear-out can be minimized while enhancing overall control during turning.

In my experience as a woodturner, I’ve found that having a deep understanding of high-speed steel has significantly improved my work quality due to its durability and cutting performance.

Benefits of High-Speed Steel Tools

Durability and Performance

High-speed steel hollowing tools are renowned for their exceptional durability. They maintain their cutting edge even after extended use, thanks to the robust nature of high-speed steel. Factors such as tool design, sharpness, and technique significantly influence the performance of hollowing tools. The right combination of these factors can result in precise and efficient woodturning.

The longevity of high-speed steel hollowing tools is a significant advantage for woodturners. With proper care, these tools can last a lifetime while maintaining cutting efficiency. This durability reduces the frequency of replacements, making them a cost-effective choice in the long run. Moreover, high-speed steel’s superior strength and resilience ensure consistent results with each use.

Personal Note: I have found that investing in high-quality hollowing tools enhances my woodworking experience and saves me money over time due to their prolonged lifespan.

Precision in Woodturning

One significant benefit of using hollowing tools is achieving precision in woodturning. These specialized tools allow woodturners to create intricate details and smooth finishes within the interior of turned objects. Through practice and attention to the point, woodturners can master techniques that result in refined craftsmanship.

Precision requires focusing on tool control, technique refinement, and selecting suitable hollowing tools for specific projects. Woodturners who prioritize precision find that high-speed steel hollowing tools offer consistency and reliability when working on detailed or delicate turning projects.

Longevity and Cost-Effectiveness

Investing in high-speed steel hollowing tools ensures longevity while being cost-effective in the long term due to reduced replacement needs.

Introduction to Basic Systems

Getting Started

To begin using hollowing tools for woodturning, it’s crucial to understand the different types of devices and their applications. Learning the proper technique through consistent practice is essential for achieving desired results. Starting with basic hollowing systems allows beginners to explore cutting techniques before investing in specialized tools.

When I first started, practicing with a simple carbide cutter helped me understand how to control the tool effectively. It allowed me to experiment with different angles and cuts without feeling overwhelmed by complex features right away.

System Selection

When selecting a hollowing system, consider project requirements, budget, and personal preferences. Basic hollowing systems offer versatility and cost-effectiveness for many turning projects. Specialized tools like easy Followers provide easy use and enhanced control for specific applications.

I found that starting with a basic set gave me the flexibility to try out different styles of woodturning projects without breaking the bank. As my skills improved, I was able to invest in more specialized tools tailored to my specific needs.

Learning Curve

Using hollowing tools effectively requires practice and patience to master proper technique. Beginners may experience a learning curve when starting with these tools, but seeking guidance from experienced woodturners or attending workshops can help shorten this process.

Attending workshops was incredibly beneficial as I received hands-on guidance from seasoned professionals who shared valuable tips on mastering hollow forms effectively.

Features of Easy Hollower

Hollowing tools for woodturning are designed to efficiently remove material from the interior of turned objects. Adequately sharpened tools and good technique are crucial in achieving optimal cutting efficiency. For instance, using sharp carbide cutters on hollowing tools can significantly improve their cutting performance, allowing woodturners to work quickly and precisely.

Choosing the right tool design is also essential for enhancing cutting efficiency. Different projects may require different tool designs, such as straight or curved shafts, depending on the depth and shape of the hollow area being created. By selecting the appropriate tool design for a specific project, woodturners can maximize their cutting efficiency while minimizing effort.

Ergonomic Design

Ergonomics ensures user comfort and control using hollowing tools, including easy hollowers. The ergonomic handles of these tools are designed to reduce fatigue during extended use, providing better maneuverability and control over the cutting process. Woodturners need to choose tools that feel comfortable in their hands, as this contributes to optimal performance.

Personal experience: using hollowing tools with ergonomic designs significantly reduces hand fatigue during long turning sessions. This allows me to focus more on my craft without experiencing discomfort or strain.

Tool Control

Maintaining control over hollowing tools is critical for achieving desired shapes and finishes in woodturned objects. Proper grip, body positioning, and precise tool movement all contribute to effective tool control during the hollowing process. Woodturners should practice controlled cuts to minimize tear-out and enhance overall precision in their woodturning projects.

Woodturners often develop techniques for controlling hollowing tools based on personal preferences and experiences gained through consistent practice.

Techniques Using High-Speed Steel Tools

Sharpening and Maintenance

Regular sharpening is crucial to keep the cutting edge of hollowing tools sharp, ensuring smooth and precise wood removal. Different sharpening techniques are used based on the type of tool steel, such as high-speed steel (HSS) or powdered metallurgy (PM) steel. Proper maintenance, including cleaning after use and rust prevention, is essential for prolonging the lifespan and maintaining the optimal performance of hollowing tools.

For instance, I constantly clean my hollowing tools after each use to prevent any wood residue from affecting their performance. I regularly inspect them for any signs of rust to address them promptly and maintain longevity.

Advanced Hollowing Techniques

Once woodturners have mastered basic techniques with hollowing tools, they can progress to advanced methods like undercutting or spiraling cuts. These advanced techniques enable artisans to create intricate designs within the interior of turned objects, adding a unique touch to their work. However, mastering these advanced hollowing techniques demands more skill and control due to the intricacy involved.

In my experience with woodturning using high-speed steel tools, I found that practicing these advanced hollowing techniques enhanced my skills and allowed me to explore more creative possibilities in my craft.

Safety Tips

Safety should always be a top priority when using hollow-turning tools. During operation, artisans must wear appropriate safety gear, such as eye protection and a face shield. Furthermore, securing the lathe firmly and properly fastening the workpiece before starting is crucial for accident prevention. Woodturners must also be cautious against tool catches while maintaining a safe distance from rotating parts throughout the turning process.

I prioritize safety by ensuring that all necessary protective gear is worn before operating woodworking equipment or handling materials.

Exploring Basic Hollowing Systems

System Components

Essential hollowing tools for woodturning consist of a handle, tool rest, and interchangeable cutting tools. The handle is necessary for a comfortable grip and precise control when turning. Tool rests are crucial in supporting the cutting tool while shaping the wood.

The handle of hollowing tools for woodturning allows me to maintain stability and accuracy when creating intricate designs on wooden objects. Having interchangeable cutting tools provides flexibility in adapting to different hollow form requirements.

Usage and Application

Hollowing tools for woodturning are indispensable in crafting various hollow forms such as bowls, vases, boxes, and similar objects. These tools find extensive application across both green and seasoned wood projects. Woodturners rely on these instruments to produce symmetrical and aesthetically pleasing designs.

When working with hollowing tools, I’ve found them particularly useful when aiming to craft unique shapes within my woodworking projects. Their versatility enables me to explore different design possibilities while ensuring precision.

Benefits and Drawbacks

Utilizing hollowing tools for woodturning presents numerous benefits, including expanded design options and the ability to fashion complex shapes quickly. However, beginners may encounter a learning curve while mastering their usage. Regular sharpening maintenance is also necessary but ensures consistently high performance from these specialized instruments.

Overview of Easy Followers

Design and Construction

Easy Hollowers are designed with specific angles and profiles to optimize cutting performance. The unique design allows for efficient wood removal while minimizing the risk of catches. These tools are constructed with high-quality materials, ensuring stability and longevity. Different designs cater to hollowing needs, such as straight or curved tools.

The angled shape of the tool’s shaft enables woodturners to reach deep into a vessel without constantly changing the handle position. This feature reduces strain on the turner’s body during extended use. Some Easy Hollowers come with interchangeable tips, providing versatility in achieving different cutting profiles.

The sturdy construction of these tools gives me confidence when working on intricate projects that require precision and control.

Versatility in Woodturning

Easy Hollowers offer versatility by allowing woodturners to create a wide range of hollow forms. Whether it’s making vases, bowls, or boxes, these tools provide the flexibility needed for diverse turning projects. They can be used on different types of wood, including softwoods and hardwoods.

With proper technique and practice, I’ve found that these hollowing tools enable me to achieve various shapes and sizes within my turned pieces. From gentle curves to sharp angles inside a vessel, the Easy Hollower #2 has become an indispensable tool in my wood-turning arsenal.

Closing Thoughts

After exploring the various hollowing tools for woodturning and delving into the features and benefits of high-speed steel tools, it’s evident that the choice of tools significantly impacts the woodturning experience. Understanding the intricacies of high-speed steel, basic hollowing systems, and easy hollowers equips woodturners with the knowledge to make informed decisions based on their specific needs and projects. The comparison of hollowing tools further highlights the importance of selecting the right tool for efficient and precise woodturning.

As you continue your woodturning journey, I encourage you to consider the insights shared here and evaluate which hollowing tools align best with your requirements. Experiment with different tools and techniques to discover what works best for you. By continuously refining your tool selection and honing your skills, you can elevate your woodturning craft to new heights.

Frequently Asked Questions

What are the advantages of using high-speed steel tools for woodturning?

High-speed steel tools offer superior durability, edge retention, and heat resistance compared to traditional carbon steel tools. They provide extended tool life and maintain their sharpness longer, resulting in cleaner cuts and reduced sharpening frequency.

How do basic hollowing systems differ from easy hollowers?

Basic hollowing systems typically involve a straight bar with a cutting tip that requires more manual control and skill. Easy Hollowers feature carbide cutters mounted on curved bars, offering easier maneuverability and reducing the learning curve for beginners.

What sets high-speed steel tools apart from other types of hollowing devices?

High-speed steel tools stand out due to their exceptional hardness, wear resistance, and ability to withstand high temperatures without losing their cutting edge. These qualities make them ideal for demanding woodturning applications such as deep hollowing.

Are there specific techniques recommended when using high-speed steel tools for woodturning?

Maintaining consistent tool rest support when using high-speed steel tools is essential, as utilizing light pressure while cutting prevents overheating the tool or workpiece and employing proper body positioning and movement to achieve smooth cuts with minimal effort.

How can I choose between different hollowing tools based on my skill level and project requirements?

Consider your level of experience, the complexity of your project, desired ease of use, and your budget when choosing between basic systems or easy followers. High-speed steel may be preferred for long-lasting performance in demanding turning scenarios.